Description

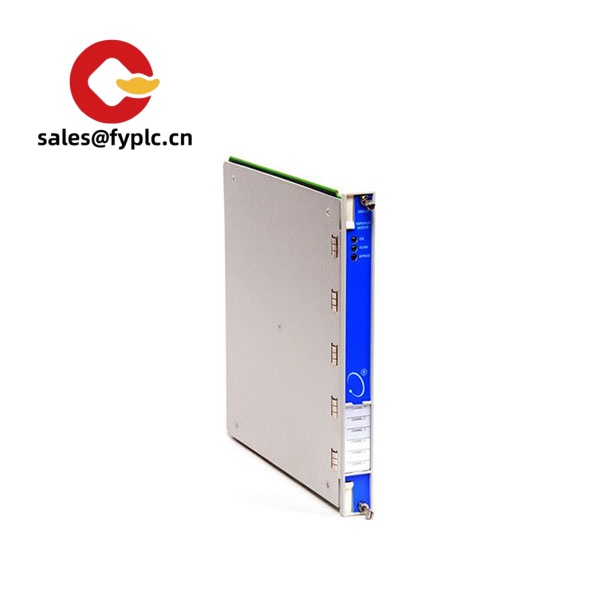

Bently Nevada 350061-01-00 (3500/61 Temperature Monitor) – Multi‑channel temperature monitoring for the 3500 rack

The Bently Nevada 350061-01-00 corresponds to the 3500/61 Temperature Monitor, designed for precise, rack‑based temperature measurement using RTDs and thermocouples. It drops into a 3500 rack and pairs with the dedicated rear I/O module to bring plant temperatures into System 1 software and plant historian links. From my experience, it’s the go‑to option when you want reliable temperature trending alongside vibration and speed data in one platform.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Shipping: Express options via FedEx, UPS, or DHL

Key Features

- Temperature inputs (RTD & thermocouple) – Supports common industrial RTDs (e.g., Pt100, typically 3‑wire) and standard thermocouple types (J/K/E/T/R/S/B), depending on I/O option set.

- Multi‑channel monitoring – Designed for multiple temperature points in a single slot, which in many cases reduces rack footprint per point.

- Seamless 3500 integration – Works within the 3500 rack, with alarming, voting logic, and display consistent with other Bently Nevada monitors.

- System 1 connectivity – Configuration and trending through the rack’s TDI; data sharing to DCS/PLC via a 3500/92 Modbus gateway if fitted.

- Field‑proven reliability – Typically deployed on turbines, compressors, large motors, and gearboxes where stable temperature trending matters.

- Serviceable design – Front card pairs with a dedicated rear I/O module; field terminations remain intact when swapping the front card.

- Alarm flexibility – Setpoints, OK status, and channel bypass functions consistent with the 3500 platform.

Technical Specifications

| Item | Details |

|---|---|

| Brand / Model | Bently Nevada 350061-01-00 (3500/61 Temperature Monitor, option code -01-00) |

| HS Code (reference) | 9031.80 – Measuring or checking instruments; final classification may vary by country/region |

| Power Requirements | Powered via the 3500 rack backplane; no external field power to the front module |

| Signal Input Types | RTDs (e.g., Pt100) and Thermocouples (J/K/E/T/R/S/B), depending on the matched 3500/61 I/O module |

| Signal Outputs | To 3500 rack backplane; alarms and values available via rack display, TDI/System 1, and (if installed) 3500/92 Modbus gateway |

| Communication Interfaces | Through 3500/22 TDI (for configuration and System 1); optional 3500/92 for Ethernet/Modbus data to DCS/PLC |

| Installation Method | Front plug‑in monitor for 3500 rack; mates with a dedicated rear I/O module for field wiring |

| Dimensions & Weight | Standard 3500 monitor form factor (single front slot); compact footprint; weight typical for 3500 monitor cards |

| Operating Temperature | Typically 0°C to +65°C (indoor, panel‑mounted); use within published 3500 rack environmental limits |

Application Fields

You’ll usually see the 3500/61 tied to critical rotating assets and auxiliary systems where temperature is an early indicator of trouble:

- Steam and gas turbines – bearing metal temperature, casing, and seal temperature trending

- Compressors, expanders, and large motors – windings, bearing housings, and cooler outlet temperatures

- Gearboxes – oil sump and bearing metal temperatures for load/viscosity shifts

- Balance‑of‑plant skids – lube oil, seal oil, and process line temperatures integrated with vibration

- Refining, petrochem, power generation – where central condition monitoring and alarm management are already on the 3500 platform

Advantages & Value

- Unified platform – Temperature in the same rack as vibration and speed simplifies spares, training, and cybersecurity considerations.

- Lower installed cost per point – In many cases, multi‑channel density reduces panel space and wiring compared to stand‑alone temperature transmitters.

- Data fidelity – Alarm logic and OK/status handling are consistent with 3500 best practices; fewer false trips when configured correctly.

- Lifecycle support – Mature ecosystem with documented spares; compatible with System 1 for diagnostics and asset strategies.

Feedback we hear a lot: “We swapped the front card in under 10 minutes and didn’t have to touch the field terminations—trending picked up right away.” That’s usually how maintenance wants it.

Installation & Maintenance

- Cabinet & rack – Install in a Bently Nevada 3500 rack mounted in a clean, ventilated enclosure; keep ambient within the rack’s specified limits.

- Wiring – Route RTD/TC cables separately from high‑voltage lines; maintain correct shielding and polarity for thermocouples; observe 3‑wire/4‑wire practices for RTDs.

- I/O pairing – Match the front 3500/61 monitor with the correct rear I/O module; cold junction compensation for thermocouples resides at the I/O.

- Hot‑swap practice – The 3500 platform supports online replacement, but it’s best to follow site MOC and silencing procedures to avoid nuisance alarms.

- Commissioning – Verify channel types, ranges, linearization, and alarm setpoints; validate with a calibrator or simulated inputs.

- Routine care – Periodic point checks, terminal re‑torque, dust cleaning of the rack, and firmware updates through the TDI as recommended.

- Documentation – Keep as‑built channel lists and option codes (-01-00 here) on file for quicker spares matching.

Quality & Certifications

- Certifications: CE; UL/cUL for industrial control equipment; RoHS compliance on most recent builds (specific marks may vary by batch)

- Hazardous area: commonly available 3500 rack certifications for Class I, Div 2/Zone 2 installations when used as a system; verify nameplate

- Manufacturer’s warranty: typically 1 year from the factory; we provide a 365‑day warranty on supply

Compatible/Supporting Components

- 3500/22 TDI – Rack interface for configuration and System 1 connectivity

- 3500/92 Communications Gateway – Ethernet/Modbus data link to DCS/PLC

- 3500 Racks & Power Supplies – Standard 19″ racks with single or redundant supplies

- Appropriate 3500/61 I/O Modules – Matching rear I/O to suit RTD or thermocouple applications

If you’re refreshing spares, the 350061-01-00 seems to be a safe, widely deployed option for temperature points in a 3500 system. Share your existing rack configuration or channel list and we’ll cross‑check the option code and I/O pairing to avoid any surprises at install.

Reviews

There are no reviews yet.