Description

Bently Nevada 9200-06-01-10-00 Velocity Seismoprobe – Reliable Case Vibration Sensing for Rotating Machinery

The Bently Nevada 9200-06-01-10-00 is a 9200 Series velocity seismoprobe designed for case-mounted vibration monitoring on pumps, compressors, turbines, gearboxes, and fans. From my experience, the 9200 series is a favorite on legacy and brownfield assets because it’s self-powered, rugged, and plays nicely with Bently Nevada 3500/1900 monitors and most third‑party condition monitoring systems. The “-10” option commonly corresponds to an integral cable length (typically around 10 ft), which makes installation tidy in many cabinets without needing extensions.

Our Order Process & Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Self-powered velocity sensing – Moving-coil design generates a dynamic voltage proportional to case vibration; no external power required.

- Case-mounted measurement – Ideal for bearing housings and machine casings where direct shaft probes aren’t practical.

- Industrial frequency band – Covers the typical machinery vibration range for balance, misalignment, looseness, and mechanical resonance checks.

- Integral shielded cable – The “-10” build typically indicates an integral cable length suited for neat routing to the junction box or monitor.

- Broad monitor compatibility – Works with Bently Nevada 3500/3300/1900 series and most vibration inputs expecting a velocity signal.

- Rugged build – Sealed, field-proven construction for harsh industrial environments with stable long-term sensitivity.

Technical Specifications

| Brand / Model | Bently Nevada 9200-06-01-10-00 (9200 Series Velocity Seismoprobe) |

| HS Code | 903180 (Other measuring or checking instruments) |

| Power Requirements | Self-powered moving-coil sensor; no external supply. Two-wire dynamic voltage output. |

| Signal Output Type | Dynamic velocity signal (mV per mm/s or mV per ips), polarity per wiring; shielded cable. |

| Frequency Response | Typical 10 Hz to 1 kHz band suitable for general rotating machinery vibration. |

| Operating Temperature | Typically -29 to +93 °C for standard 9200 series variants (confirm option-specific limits). |

| Communication Interfaces | None (analog passive sensor) |

| Installation Method | Stud-mount to machine case; mount on a flat, clean surface; route shielded cable to monitor/ junction box; maintain strain relief. |

| Cable / Connection | Integral shielded cable; “-10” option typically ≈10 ft length; two conductors plus shield to monitor input. |

Application Fields

You’ll typically see the 9200 on:

- Power generation – steam turbines, generator bearings, boiler feedwater pumps.

- Oil & gas – compressors, pumps, and API-compliant trains where case vibration trending is standard.

- Chemicals & petrochem – large process pumps and fans with continuous monitoring.

- Pulp & paper, mining, cement – rugged drive trains and critical conveyors/fans.

One thing I appreciate is how the 9200 series handles low-frequency machinery issues. In many cases, you get cleaner velocity trends without needing an external integrator, which keeps channel configuration simple in the rack.

Advantages & Value

- Compatibility – Drop-in fit for Bently Nevada 3500/3300/1900 monitors and widely supported by third‑party CM systems.

- Low lifecycle cost – No power supply, minimal failure modes, and straightforward spare strategy.

- Reliable trending – Stable sensitivity for long-term case vibration baselining and alarms.

- Simple wiring – Two-wire dynamic output reduces channel complexity compared to accelerometer + integrator setups.

- Procurement certainty – Mature, widely deployed product line with predictable performance and stocking options.

Installation & Maintenance

- Mounting – Stud-mount on a smooth, clean surface close to the bearing housing. Maintain consistent orientation across machines for comparable data.

- Wiring – Use the integral shielded cable; land the shield at the monitor/junction box per plant grounding practices. Keep clear of VFD and high-voltage runs to reduce noise.

- Cabinet & environment – Route into a ventilated cabinet or junction box; use proper strain relief and avoid tight bend radii.

- Safety – De-energize adjacent equipment during installation. If installed in hazardous areas, verify the exact option code approvals before commissioning.

- Upkeep – Inspect mounts and cable strain relief during outages. Verify channel sensitivity during periodic calibrations and update monitor firmware/settings as required.

Field remark from a maintenance supervisor (combined-cycle plant): “Swapped to 9200s on the main condensate pumps last outage. Cabling was straightforward, and the 3500 channels lined up with our existing alarm setpoints with minimal rework.”

Quality & Certifications

- CE conformity and RoHS compliance are available on standard 9200 series builds.

- Hazardous-area approvals (e.g., ATEX/IECEx/CSA) exist on certain option codes; confirm against 9200-06-01-10-00 before use in classified zones.

- Our warranty: 365 days from delivery.

Related Compatible Components (for a complete solution)

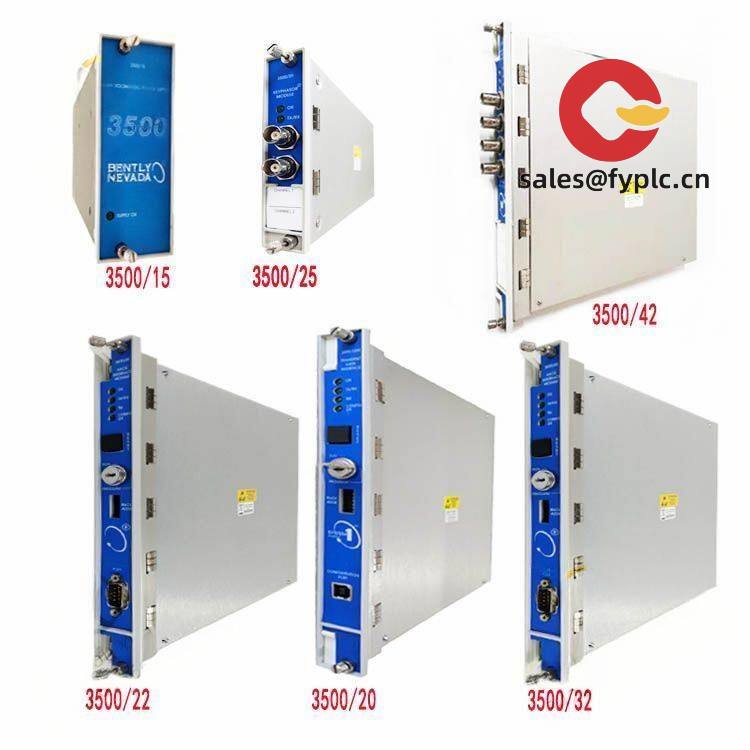

- Bently Nevada 3500 Series rack monitors (e.g., 3500/42M) for velocity channels and alarms.

- Bently Nevada 1900/65A or 1900/55 monitors for stand‑alone machine protection.

- Junction boxes and stainless mounting studs/adapters for difficult surfaces.

- Shielded extension leads and cable glands suitable for the 9200 series integral cable OD.

If you’re standardizing on case vibration for critical pumps and fans, this 9200-06-01-10-00 build hits a practical balance: fast to deploy, dependable signal quality, and in most cases no surprises during commissioning. If you’d like, share your monitor model and channel card type; I can double‑check sensitivity settings and wiring polarity so your first trend looks right from day one.

Reviews

There are no reviews yet.