Description

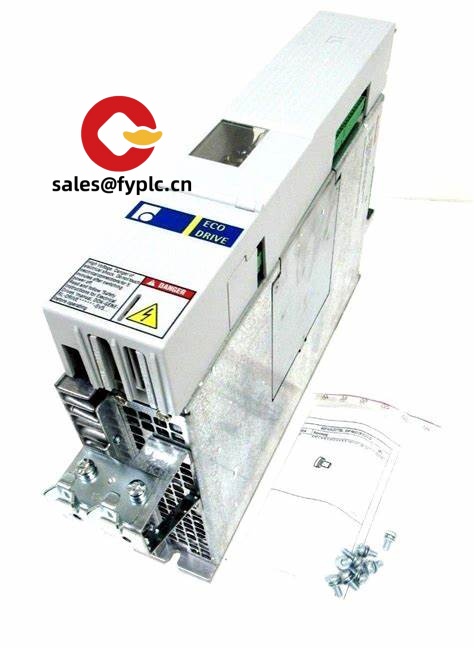

Bosch Rexroth DKC01.3-012-3-MGP-01VRS – EcoDrive 03 single‑axis servo drive for 3×230 V systems

The DKC01.3-012-3-MGP-01VRS is a compact Bosch Rexroth (Indramat) EcoDrive 03 digital servo drive, typically used to run MKD/MHD synchronous servo motors or 2AD asynchronous motors in packaging, printing, and handling equipment. One thing I appreciate is the MGP “multi-interface” firmware: it gives you straightforward analog ±10 V control and fast digital I/O without forcing a fieldbus redesign. From my experience, this variant is a safe pick for retrofits where you need a 12 A class axis on a 3×200–230 VAC supply and want predictable commissioning.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- 12 A axis rating – Sized for small to mid‑torque applications; common on feeders, unwinders, gantries, and indexers.

- 3×200–230 VAC mains – Fits low‑voltage three‑phase cabinets; simplifies brownfield upgrades on 230 V lines.

- MGP multi‑interface control – Analog ±10 V setpoint, step/direction, and fast 24 V I/O for enable, homing, limit, and mode signals.

- Motor compatibility – Works with Bosch Rexroth Indramat MKD/MHD synchronous servo motors and, in many cases, 2AD induction motors with appropriate feedback.

- Service/diagnostic port – RS‑232 for parameterization and trace with Rexroth tools; helpful during commissioning and fault analysis.

- Booksize form factor – Space‑efficient panel mounting; you might notice it fits neatly in existing EcoDrive 03 lineups.

- Integrated brake chopper – External resistor connection for dynamic deceleration on high‑inertia moves.

- Protection and monitoring – Overcurrent, overvoltage/undervoltage, and thermal monitoring to protect the drive and motor.

Technical Specifications

| Brand / Model | Bosch Rexroth DKC01.3-012-3-MGP-01VRS (EcoDrive 03) |

| HS Code | 8504.40 (Static converters / servo drive) |

| Power Requirements | 3×200–230 VAC, 50/60 Hz; axis current class 12 A; integrated DC bus and brake chopper |

| Operating Temperature | 0 to +45 °C (typical for EcoDrive 03; allow derating near upper range) |

| Signal I/O Types | Analog ±10 V setpoint; step/direction (pulse/dir); 24 V digital inputs/outputs for control and status; motor encoder feedback connections (Rexroth/Indramat types) |

| Communication Interfaces | RS‑232 service/diagnostics (DriveTop parameterization). MGP variant focuses on analog/digital control rather than native fieldbus. |

| Installation Method | Panel (booksize) mounting in a control cabinet, vertical orientation; front‑access terminals |

| Dimensions & Weight | Booksize “size 01” housing; compact footprint commonly used in EcoDrive 03 stacks |

| Protection Class | IP20 (cabinet installation) |

Application Fields

This model shows up a lot in brownfield upgrades where machine builders keep their motion profiles but refresh the axis hardware. Typical use cases include:

- Packaging machines – rotary sealers, cartoners, and intermittent index tables using analog speed or position loops

- Printing & converting – unwind/rewind tension control and register correction on 230 V panels

- Textile & woodworking – feed rollers, spindles, and positioning axes where fast I/O is sufficient

- Material handling – pick-and-place, small gantries, and tool changers with quick homing cycles

A packaging OEM told us their swap from a legacy analog amplifier to this DKC cut their changeover time because the I/O mapping and gain tuning were more forgiving—no PLC rewrite, just a tidy MGP setup and they were running.

Advantages & Value

- Reliability: EcoDrive 03 hardware has a strong field record; spare parts and knowledge are still widely available.

- Compatibility: Plays nicely with existing 230 V cabinets, MKD/MHD motors, and analog control architectures.

- Cost control: In many cases you keep your PLC code and wiring—savings come from shorter downtime and fewer new components.

- Support: We can assist with parameter backups, MGP I/O mapping, and selecting matched braking resistors and filters.

Installation & Maintenance

- Cabinet & mounting: Install vertically in an IP54 (or better) control cabinet. Allow top/bottom clearance for airflow; avoid heat sources directly beneath the unit.

- Wiring: Use shielded motor and feedback cables; bond shields 360° at the entry. Keep power and signal runs separated. Verify PE grounding and braking resistor sizing.

- Environment: Operate within 0…45 °C and low dust/moisture. If cabinet temps run high, derate or improve ventilation.

- Commissioning: Through RS‑232, save/restore parameter sets. Check motor nameplate data, feedback type, and current limits before enabling torque.

- Routine care: Annually check fan and heatsink cleanliness, terminal tightness, and brake resistor connections. Firmware updates should match MGP release “01VRS”.

- Safety: Lockout/tagout mains; verify DC bus discharge. Test E‑stop chain and hardware limits after any wiring change.

Quality & Certifications

- CE compliant; UL/cUL conformity is typical for this series

- RoHS alignment for electronic assemblies where applicable

- Manufacturer quality system: ISO 9001

- Warranty coverage: 365 days

Helpful Companion Parts (for quicker selection)

- Motors: MKD and MHD series (e.g., MKD071, MKD090) and, in many cases, 2AD induction motors

- Braking resistor: external resistor sized for the kinetic load and duty (EcoDrive 03 compatible)

- Mains line filter/reactor: to meet EMC and protect against supply disturbances

- Cabling: motor power cable with brake cores, feedback cable matched to the motor’s encoder system

If you’re replacing a legacy DKC in an older machine, send the drive ID plate and motor type. We can cross‑check the 12 A rating, MGP interface needs, and braking resistor so the new unit drops in with minimal rewiring.

Reviews

There are no reviews yet.