Description

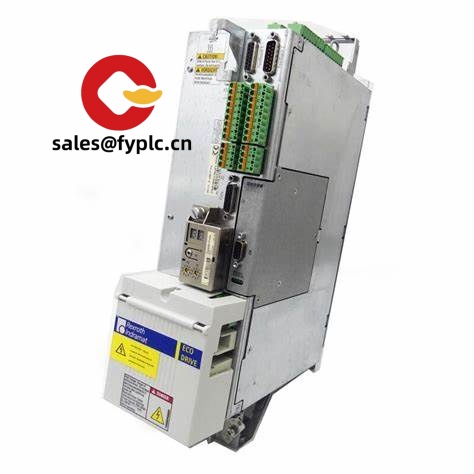

Bosch Rexroth DKC11.3-100-7-FW – High‑power ECODRIVE servo drive for reliable machine axes

The Bosch Rexroth DKC11.3-100-7-FW is part of the ECODRIVE family, built for precise motion control on medium to high‑power axes. From my experience, this unit is a solid fit when you need stable torque, clean positioning, and proven compatibility with legacy Indramat motors like MDD/MKD, without overcomplicating the control architecture. You might notice that it slots neatly into existing cabinets where an upgrade or quick swap is needed—especially in packaging, metalworking, or printing lines where downtime is costly.

Company’s Order Placement Process and Guarantees

-

- – Warranty period: 365 days

-

- – Delivery time: 1 week for in-stock; no more than one month at the latest

-

- – Payment method: 50% advance payment, full payment for delivery

- – Express delivery methods: FedEx, UPS, DHL

Key Features

- High-power “100” class stage – Suited for larger servo axes that demand strong continuous current and robust peak handling.

- 380–480 VAC mains – The “7” code typically denotes three‑phase 380–480 VAC, making it straightforward to integrate in most industrial panels.

- ECODRIVE control platform – Stable, mature control behavior with proven tuning methods for fast commissioning.

- Flexible command options – Common setups include ±10 V analog velocity/torque command, digital I/O, and a service/PC port for parameterization.

- Motor feedback support – Designed to operate with Bosch Rexroth/Indramat servo encoders used on MDD/MKD and related motors.

- Serviceable firmware module (FW) – The FW variant indicates dedicated firmware storage for easy replacement and backup.

- Cabinet-friendly footprint – Vertical panel mounting with attention to airflow; typically fits standard European cabinet layouts.

Technical Specifications

| Brand / Model | Bosch Rexroth DKC11.3-100-7-FW (ECODRIVE servo drive controller) |

| HS Code | 8504.40 (Static converters / AC drive units) |

| Power Requirements | 3‑phase 380–480 VAC, 50/60 Hz (typical for “7” mains code) |

| Power / Current Class | “100” class power stage for medium to high-power axes (consult motor/load sizing) |

| Operating Temperature | 0 to +45 °C ambient (typical cabinet conditions) |

| Signal I/O Types | Analog ±10 V command, digital inputs/outputs, motor encoder feedback (Indramat/Rexroth) |

| Communication Interfaces | Service/PC port (RS‑232) for parameterization; SERCOS or other bus options may be configuration‑dependent |

| Installation Method | Vertical panel mounting in enclosed control cabinets; maintain top/bottom clearances for airflow |

| Dimensions & Weight | Compact ECODRIVE housing; approx. 390 × 100 × 300 mm, ~9–11 kg (varies by version) |

Application Fields

This drive typically shows up in:

- Packaging and converting machines where quick indexing and repeatable positioning are critical.

- Machine tools and metal processing lines requiring steady torque control for larger axes.

- Printing and woodworking systems that need coordinated multi‑axis motion with reliable uptime.

- Material handling, palletizing, and gantry axes using MKD/MHD servo motors.

Advantages & Value

- Compatibility – Works with a wide range of Bosch Rexroth/Indramat servo motors and feedback types, which often simplifies retrofits.

- Proven reliability – ECODRIVE hardware has a solid track record in 24/7 production; spares and know‑how are widely available.

- Lower total cost – In many cases, keeping ECODRIVE architecture avoids re‑engineering your control system and new safety approvals.

- Serviceability – Parameter backup via firmware module and RS‑232 tools typically shortens recovery after a fault or replacement.

Installation & Maintenance

- Panel/cabinet requirements – Mount vertically on a metal backplate; allow ventilation clearances top and bottom; keep ambient within 0–45 °C and humidity non‑condensing.

- Power & grounding – Use 3‑phase 380–480 VAC with appropriate line protection, EMC filter, and (where required) a line reactor. Bond PE/ground with low impedance.

- Cabling – Shielded motor and encoder cables; separate power and signal routing to reduce noise. Maintain proper ferruling and strain relief.

- Commissioning – Parameterize via Bosch Rexroth tools (e.g., service RS‑232) and store backups. Run autotuning with the target load, then fine‑tune.

- Routine maintenance – Quarterly dust removal, visual checks on fans/vents, terminal torque checks, and annual parameter/firmware backup. Replace fans/electrolytics per service life if the unit runs hot.

- Safety – Isolate mains and wait for DC bus discharge before servicing. Verify that any external E‑stop, enable chains, and interlocks are wired and tested.

Quality & Certifications

- Typically CE marked for industrial environments; many variants carry UL/cUL recognition.

- Manufactured to Bosch Rexroth quality standards; firmware traceability via the FW module.

- 365‑day warranty coverage from shipment date.

Suggested Accessories & Compatible Components

- Matching Bosch Rexroth motors: MKD, MDD, MHD series (verify shaft/feedback compatibility).

- SERCOS fiber pair or control cables (if using fieldbus options), RS‑232 service cable for commissioning.

- EMC mains filter, line reactor (as required by installation), braking resistor sized for the application.

- Motor power/feedback cable sets with proper shielding and connectors.

One thing I appreciate is how the DKC11.3-100-7-FW typically shortens retrofit timelines—swap, load parameters, run a quick tune, and you’re back in production. If your axis sizing or bus configuration seems unique, share the motor typeplate and we’ll validate the exact firmware and accessory set before shipment.

Reviews

There are no reviews yet.