Description

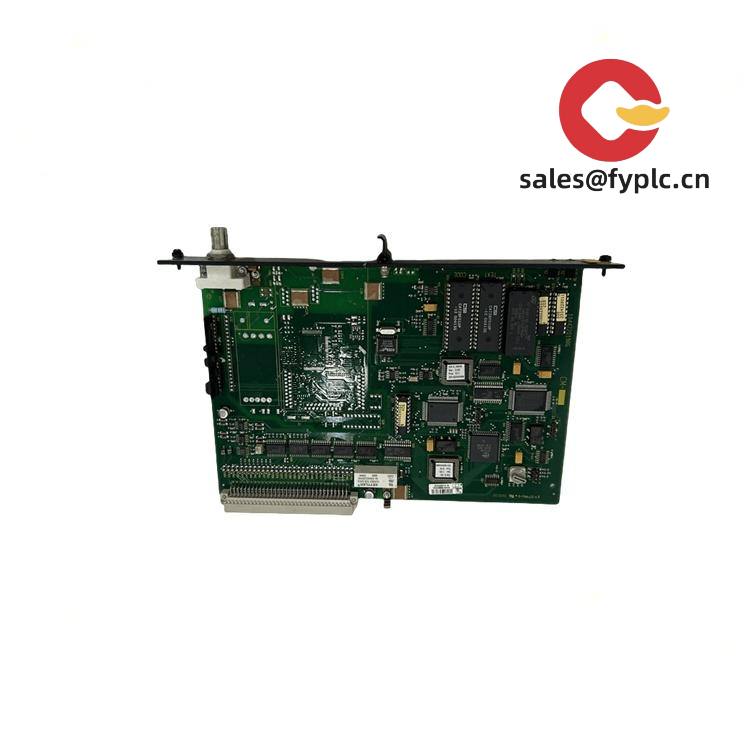

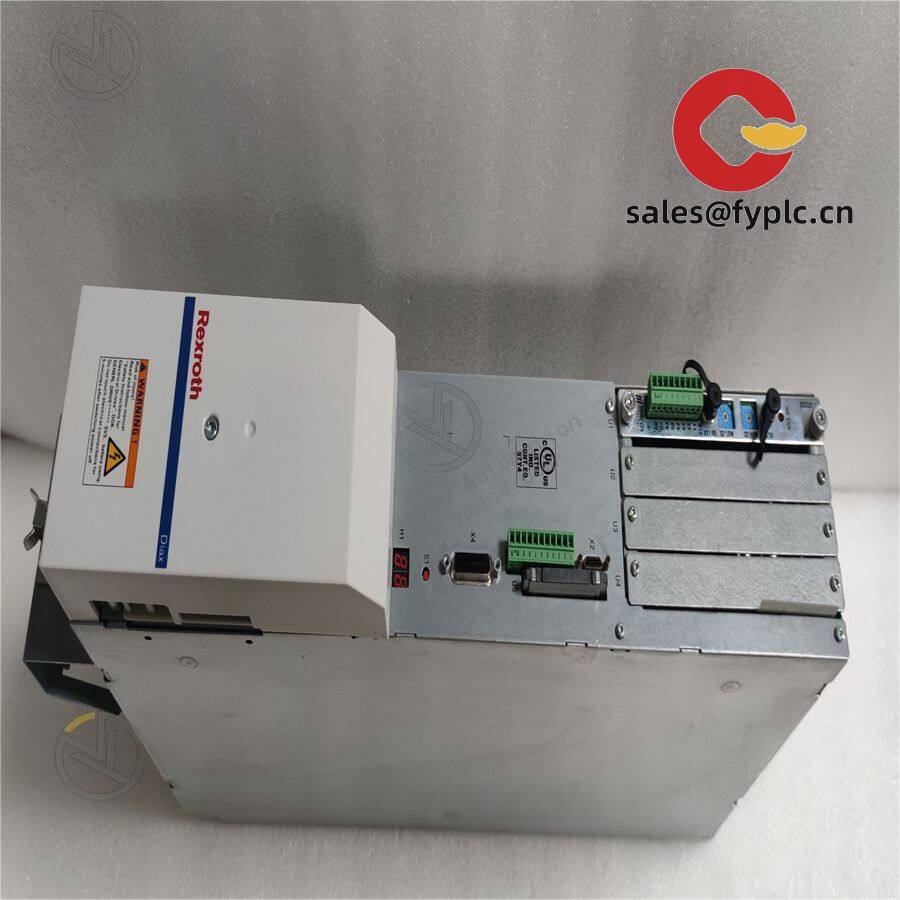

Bosch Rexroth HDS03.2-W075N-HS12-01-FW (R911190008) – Booksize Drive Controller for DIAX04 Multi-Axis Servo Systems

The Rexroth/Indramat HDS03.2-W075N-HS12-01-FW is a proven axis drive controller from the DIAX04 family, used widely in packaging lines, CNC machinery, and high-speed automation cells. From my experience, this unit shines when you need reliable multi‑axis performance on a common DC bus with clean SERCOS motion control. The “-FW” suffix indicates the firmware module is handled separately—most users reuse a known-good firmware card to maintain parameter compatibility across machines.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- SERCOS fiber-optic interface (HS12)

– deterministic motion bus for precise multi-axis coordination and straightforward parameter handling. - Common DC bus architecture

– pairs with HVR/HVE supply modules for energy sharing and compact machine panels. - Booksize form factor

– fits tightly in DIAX04 racks; ideal where cabinet space is at a premium. - Broad motor compatibility

– typically used with Rexroth MKD, MHD, and 2AD series servo motors for medium to high dynamic axes. - Service/commissioning port

– convenient serial service interface for startup, diagnostics, and tuning. - Firmware handled separately

– the -FW variant expects a matching firmware module; that’s helpful when standardizing across lines. - Industrial-grade reliability

– robust design for 24/7 operation; typically stable in harsh factory environments.

Technical Specifications

| Brand / Model | Bosch Rexroth Indramat HDS03.2-W075N-HS12-01-FW (Part No. R911190008) |

| HS Code | 8504.40 (Static converters – for reference; final classification depends on destination country) |

| Power Requirements | DC bus supplied via HVR/HVE rectifier module (approx. 300 VDC nominal); 24 VDC control supply for logic. |

| Operating Temperature | 0 to +45°C, non‑condensing (typical cabinet-mounted operation) |

| Signal I/O Types | Digital enable/ready/fault I/O; motor feedback via Rexroth encoder interfaces (e.g., digital servo feedback or 1Vpp sin/cos depending on motor). |

| Communication Interfaces | SERCOS fiber-optic (HS12); service/diagnostic serial port (typically RS‑232). |

| Installation Method | Booksize module in DIAX04 backplane; panel/cabinet mounting with vertical airflow and protective earth bonding. |

Application Fields

This controller is commonly specified for multi-axis packaging machines, woodworking lines, printing & converting, material handling gantries, and mid-range CNC retrofits. You might notice that lines moving from analog control to SERCOS often pick the HDS03.2 modules to keep the footprint tight while boosting synchronization and diagnostics.

Advantages & Value

- Drop-in compatibility – typically fits existing DIAX04 racks and cabling with minimal rewiring, reducing downtime.

- Cost control – reusing firmware cards and motor/feedback sets can save calibration time and commissioning costs.

- Reliability – these units are known to run for years; in many cases customers report steady operation with only routine cabinet cleaning.

- Technical support – parameter backups and SERCOS diagnostics speed up service calls and machine restarts after line changes.

Installation & Maintenance

- Cabinet environment – mount vertically on a grounded backplate in an IP54 (or better) enclosure; allow unobstructed airflow. Maintain ambient 0–45°C.

- Power & wiring – feed DC bus from the matching HVR/HVE module; use shielded motor/feedback cables; separate power and signal runs to reduce noise.

- Safety – lockout/tagout the supply module; discharge DC bus fully before service. Verify PE connections and motor brake wiring.

- Firmware & parameters – ensure the firmware card matches your controller option set (HS12). Keep parameter backups on file; it saves hours during swap-outs.

- Routine care – quarterly dust removal in filters and around heatsinks; check fan operation and terminal tightness; update firmware only when required by a validated change.

- Commissioning tips – perform encoder reference runs, verify SERCOS ring status, and test enable/fault interlocks before loading production recipes.

Quality & Certifications

- Manufacturer quality system: typically produced under ISO 9001 processes

- CE compliant for industrial environments (EMC/Low Voltage)

- UL Recognized (region-dependent)

- RoHS status can vary by production year; confirm if your project requires strict RoHS compliance

- Standard warranty coverage: 365 days from delivery

One thing I appreciate is how forgiving this platform is during swaps—keep the same HS12 SERCOS setup, migrate your parameter set, and the machine is usually back in cycle quickly. If you’d like, we can pre-test an HDS03.2-W075N-HS12-01-FW (R911190008) on a live SERCOS ring with a MKD motor profile so it arrives ready to drop in.

Reviews

There are no reviews yet.