Description

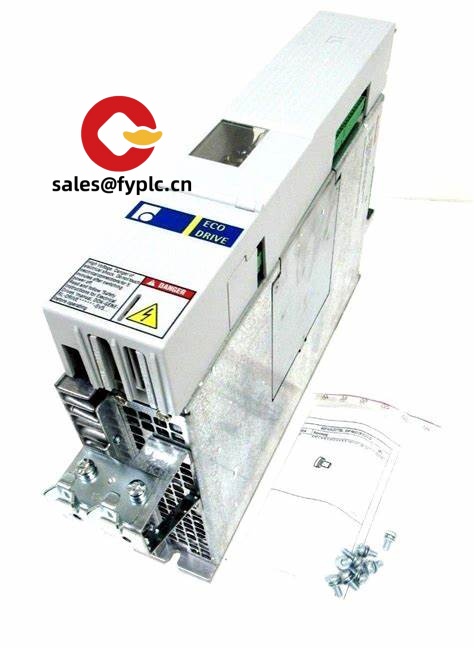

Bosch Rexroth Indramat DKC02.3-040-7-FW – ECODRIVE 03 Servo Drive Controller for 40 A Applications

This unit is part of the well-proven ECODRIVE 03 family. The DKC02.3-040-7-FW is a compact servo drive controller typically used with Rexroth MKD/MHD/MDD synchronous servo motors in packaging, printing, and general automation lines. One thing I appreciate is how straightforward it is to swap into existing panels—wiring, parameter handling, and firmware are all designed to be service-friendly, which in many cases cuts downtime to a minimum.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week when in stock; no more than 1 month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- 40 A power stage – Sized for mid-to-high torque servo axes; ideal for heavier feeders, winders, or high-inertia loads.

- ECODRIVE 03 platform – Stable, widely deployed generation with strong parts availability and predictable lifecycle support.

- Modular firmware (-FW) – Firmware supplied separately; you can match the firmware level to your installed base for consistent behavior.

- Flexible control modes – Position, velocity, and torque control for synchronous servo motors; resolver feedback supported in typical setups.

- Fieldbus options – Common interfaces (e.g., SERCOS, PROFIBUS, INTERBUS) available depending on option cards; helpful when retrofitting mixed fleets.

- Robust protection – Overcurrent, overtemperature, and DC bus monitoring functions help safeguard both drive and motor.

- Booksize, panel-mount design – Fits cleanly in standard control cabinets with top/bottom ventilation space.

- Service-friendly – Parameter backup/restore and clear diagnostics reduce commissioning time; from my experience, that’s a big win for maintenance teams.

Technical Specifications

| Brand / Model | Bosch Rexroth Indramat DKC02.3-040-7-FW (ECODRIVE 03) |

| HS Code | 8537.10 (control apparatus, ≤1000 V; typical reference for industrial drive controllers) |

| Power Requirements | 3-phase AC supply, typically 380–480 V, 50/60 Hz; integrated DC bus with braking capability (external resistor as required) |

| Current Rating | 40 A power stage (application-dependent continuous/peak values) |

| Operating Temperature | 0 to +45 °C (cabinet installation with adequate ventilation) |

| Signal I/O Types | 24 V digital I/O; analog setpoint (±10 V) supported in many configurations; resolver/encoder feedback for servo motors |

| Communication Interfaces | SERCOS, PROFIBUS, or INTERBUS via option modules (varies by installed card) |

| Installation Method | Panel/cabinet mounting (booksize); vertical orientation with top/bottom clearance for airflow; IP20 |

| Typical Pairing | Rexroth MKD/MHD/MDD servo motors; braking resistor, mains filter/choke, and shielded motor/feedback cables |

Application Fields

You’ll commonly see the DKC02.3-040-7-FW driving axes in packaging form-fill-seal machines, folder-gluers, labelers, and cartoners. It also performs well in printing lines (web tension, register control), woodworking equipment (feed and positioning axes), and general material handling. A maintenance manager told me they favor this model for retrofit projects because it “just behaves the same as the rest of our ECODRIVE rack—no surprises in tuning.”

Advantages & Value

- Drop-in compatibility – Seamless with existing ECODRIVE 03 environments; typically no cabinet redesign.

- Stable lifecycle – Parts and documentation are widely available, which seems to shorten mean time to repair.

- Cost control – Predictable commissioning and minimal engineering overhead save both time and budget.

- Supportable firmware – Separately supplied firmware lets you align versions across multiple lines to keep behavior consistent.

Installation & Maintenance

- Cabinet & ventilation – Mount vertically in a closed control cabinet to EN/IEC standards; allow unobstructed airflow above/below the heat sink.

- Wiring – Use correctly rated line protection, line reactor/filter as required, and shielded motor/feedback cables with proper grounding on the drive side.

- Braking – Size the external brake resistor for your deceleration profile; check duty cycle and ambient temperature.

- Safety – Lock out/tag out before servicing; discharge the DC bus fully; verify earthing; observe creepage/clearance.

- Commissioning – Load matching firmware, restore parameters, and run autotune. From my experience, backing up parameter sets before changes saves a lot of time.

- Routine care – Quarterly dust cleaning, connector inspection, fan check, and periodic firmware/parameter audits. Keep cabinet temperature stable to extend component life.

Quality & Certifications

- Conformity: CE; UL recognition and RoHS compliance in many cases for ECODRIVE 03 family units

- Manufacturer’s policy: standard warranty coverage typically applies when installed and operated per Rexroth guidelines

- Warranty provided here: 365 days

If you’re replacing a like-for-like unit or planning a small retrofit, share your motor type and interface card requirements. We can match firmware and option modules to keep your machine behavior identical.

Reviews

There are no reviews yet.