Description

Bosch Rexroth VT2000-52-A – Analog Amplifier Card for Proportional Valve Control

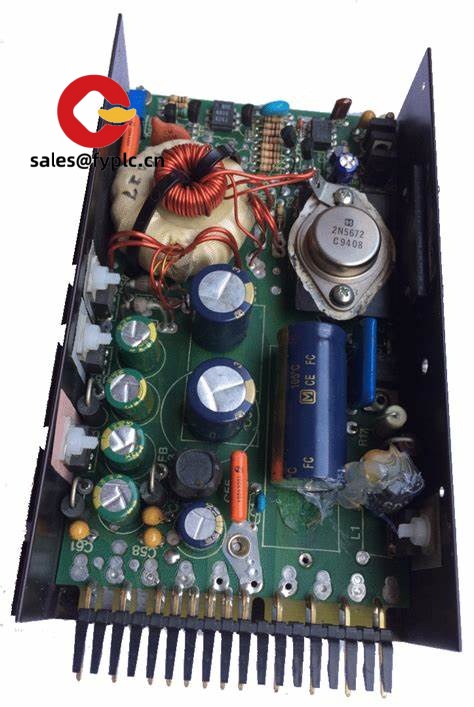

The Bosch Rexroth VT2000-52-A is an analog amplifier card designed to drive hydraulic proportional valves with stable, repeatable performance. It’s a Eurocard plug-in module that typically drops into a 19-inch subrack, giving you straightforward setup, fast commissioning, and dependable current control for one proportional solenoid. From my experience, it’s the kind of “fit-and-forget” card many maintenance teams rely on when they need to stabilize a circuit and keep machines running.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment method: 50% advance payment, full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Stable current control for proportional valves – Helps reduce hunting and improves repeatability on pressure or flow control loops.

- Analog command input – Typically accepts ±10 V or 0…10 V signals, making it easy to integrate with PLCs and motion controllers.

- Adjustable dither and gain – You can tune dither amplitude/frequency and gain to smooth out stick-slip and match valve dynamics.

- Ramp/acceleration functions – Gentle acceleration and deceleration minimize hydraulic shocks when setpoints change.

- Eurocard plug-in design – Quick swap in a 19-inch subrack; minimal wiring time and simplified service.

- Status indication – On-card LEDs (power/fault) help you diagnose at a glance, which in many cases saves a service call.

- Robust industrial build – Designed for typical machine environments where electrical noise and vibration are part of daily life.

Technical Specifications

| Item | Details |

|---|---|

| Brand / Model | Bosch Rexroth VT2000-52-A |

| HS Code | 8537.10 (Boards/panels for electric control, ≤1000 V) |

| Power Requirements | 24 V DC nominal (typical in industrial racks) |

| Dimensions & Weight | Eurocard 100 × 160 mm; approx. 0.25 kg |

| Operating Temperature | 0…+50 °C (typical for control electronics) |

| Signal Input/Output Types | Analog command input ±10 V or 0…10 V; current-controlled output to one proportional solenoid |

| Communication Interfaces | None (analog control; no fieldbus) |

| Installation Method | Plug-in Eurocard; DIN 41612 backplane connector in a 19″ subrack |

Where it typically fits

You’ll see the VT2000-52-A used on proportional pressure or directional valves in presses, injection molding machines, test rigs, and web processing lines. One thing I appreciate is how quickly it dials in a stable loop on older hydraulic power units where newer digital drives are overkill. A maintenance lead told us they swapped one into a 19″ rack and, after a short dither and gain tweak, the jitter they’d fought for months disappeared.

Related or Supporting Products

- Bosch Rexroth VT 3002-2X Subrack – 19″ rack for Eurocard amplifier modules; provides the DIN 41612 backplane and power distribution.

- Bosch Rexroth VT-HACD-1-2X – Digital axis/valve controller; often used as a modernization path when you need fieldbus, recipes, or closed-loop profiles.

- Rexroth proportional valves (e.g., 4WRZ / 4WRA series) – The VT2000-52-A is commonly paired with these for open-loop proportional control.

If you’re replacing a legacy VT2000 card, the VT-HACD-1-2X offers more diagnostics and profile control, but the analog VT2000-52-A is quicker to commission in many cases and keeps the original wiring intact.

Installation & Maintenance

- Cabinet/rack: Install in a 19″ Eurocard subrack with good airflow. Keep power and signal wiring separated to minimize noise coupling.

- Power & grounding: Use a regulated 24 V DC supply and a clean protective earth. You might notice improved stability with shielded command lines grounded at one end.

- Wiring: Follow DIN 41612 pinout. Use twisted, shielded pairs for analog inputs and valve leads; route away from motor cables.

- Tuning: Set zero, gain, ramps, and dither with the machine stationary, then verify under load. Small adjustments often make a big difference.

- Safety: De-energize the system before insertion/removal. Observe ESD precautions when handling the board.

- Routine care: Dust the rack periodically, check connector tightness, and re-verify tuning after valve replacement or hydraulic oil changes.

Quality & Certifications

- CE-compliant industrial electronics; RoHS-conform components in most series

- Manufactured under ISO 9001 quality systems

- Manufacturer’s warranty practices apply; our supply is backed by a 365-day warranty

Need help confirming compatibility with your valve coil resistance or command signal range? Share the valve model and the rack type you’re using, and we’ll validate the VT2000-52-A setup and the correct pinout before you place the order.

Reviews

There are no reviews yet.