Description

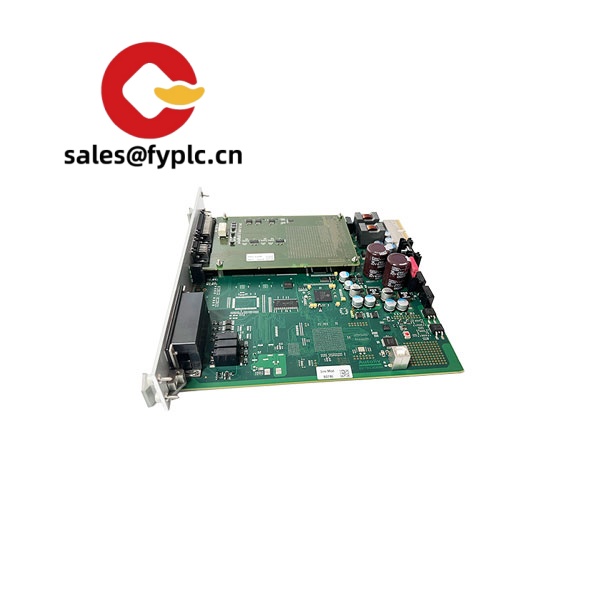

B&R 8AC120 Servo Drive – Single‑Axis Motion Control for Precise, Fast Automation

The B&R 8AC120 is part of B&R’s servo drive family designed for single-axis control with tight synchronization and quick response. From my experience, it pairs neatly with B&R PLCs and POWERLINK networks, making machine builds cleaner and commissioning faster. You might notice that it typically fits into compact panels where space and thermal headroom are limited, yet it still delivers the dynamic performance you expect for packaging, converting, and electronics assembly lines.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Single-axis servo amplification – Sized for one motor axis where precise speed/torque/position control is needed.

- POWERLINK-ready – Seamless integration with B&R controllers over Ethernet POWERLINK keeps wiring simple and diagnostics centralized.

- High dynamic response – Fast current/velocity loops help shorten cycle times on indexing, pick-and-place, and camming tasks.

- Safe Torque Off (STO) – Typically available for SIL-rated emergency stop chains, reducing external safety relay hardware.

- Compact panel footprint – Designed for cabinet installation with straightforward wiring and clear service access.

- Flexible feedback options – Supports common encoder/resolver interfaces via the applicable option, which in many cases simplifies retrofit work.

- Energy-conscious design – Brake control and DC-bus energy handling help cut heat and, in some setups, reduce external braking hardware.

Technical Specifications

| Brand / Model | B&R / 8AC120 |

| HS Code | 8504.40 (Static converters – servo drive) |

| Power Requirements | Control: 24 VDC; Main supply: 3‑phase 400 VAC class (typical for this series) |

| Operating Temperature | 0 to +50/55 °C (typical cabinet conditions) |

| Signal I/O Types | Digital enable/ready/fault; motor brake output; encoder/resolver feedback via option interface (model dependent) |

| Communication Interfaces | Ethernet POWERLINK (B&R motion networks); local service port for setup |

| Installation Method | Panel/cabinet mount on backplate; vertical orientation with ventilation clearance |

Application Fields

The 8AC120 fits single-axis tasks where repeatability and quick changeovers matter. You’ll typically see it in:

- Packaging and converting lines – form/fill/seal, feeders, seal bars, rotary knives

- Electronics assembly – PCB handling, labeling, high-speed indexing

- Intralogistics – diverters, sorters, shuttle positioning

- Machine modules – dosing screws, winders/unwinders, linear actuators

- Light machining and test equipment – spindles, fixtures, precision stages

Advantages & Value

- Integration with B&R controls – One thing I appreciate is how quickly motion axes come online in Automation Studio, which cuts commissioning time.

- Lifecycle reliability – In many cases, these units run for years with minimal drift, so maintenance windows stay predictable.

- Compatibility – Works well with B&R 8LS servo motors and POWERLINK topologies; retrofit paths are straightforward with common feedback options.

- Panel efficiency – Compact housing and efficient thermal behavior help reduce cabinet footprint and cooling load.

- Serviceability – Clear diagnostics and standard wiring lower downtime during troubleshooting.

Installation & Maintenance

- Cabinet & ventilation – Mount on a rigid backplate in a sealed cabinet; keep vertical airflow with at least 50 mm clearance above/below. Avoid direct heat sources.

- Power & wiring – Use appropriately sized mains protection, EMC line filters, and shielded motor/feedback cables. Bond shields 360° at the drive end for noise immunity.

- Grounding – Low-impedance PE connection is essential for both safety and encoder signal integrity.

- Safety – If STO is used, wire to the required SIL/PL level and verify stop behavior during commissioning.

- Routine checks – Every 6–12 months, inspect connectors, fan airflow, and dust buildup; clean with dry air and check brake function.

- Firmware & tuning – Keep firmware at a validated revision; re-run autotune after mechanical changes. Back up parameter sets via the service tool.

Quality & Certifications

- Typically compliant with CE and UL/cUL for industrial machinery environments

- RoHS conformity for restricted substances management

- Manufactured under ISO 9001 quality systems (industry standard for this category)

- Manufacturer’s warranty: 12 months from shipment

Recommended Accessories & Compatible Components

- B&R 8LS servo motors (torque classes matched to the 8AC120 rating)

- Pre-assembled motor power and feedback cables for 8LS/encoders

- External braking resistor (when high deceleration energies are expected)

- EMC mains filter and line reactor sized to mains current

- B&R PLC with POWERLINK master for multi-axis synchronization

Quick Sizing Tip

If your axis has frequent start/stop moves with short cycles, select braking and thermal options with some margin. It seems to be the easiest way to keep drive temperatures steady and avoid nuisance trips during seasonal temperature swings.

Reviews

There are no reviews yet.