Description

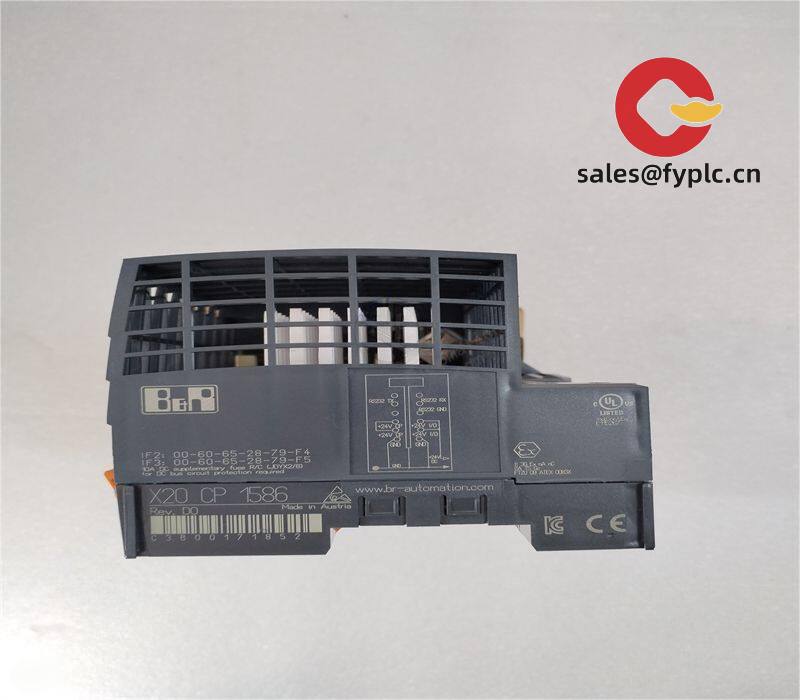

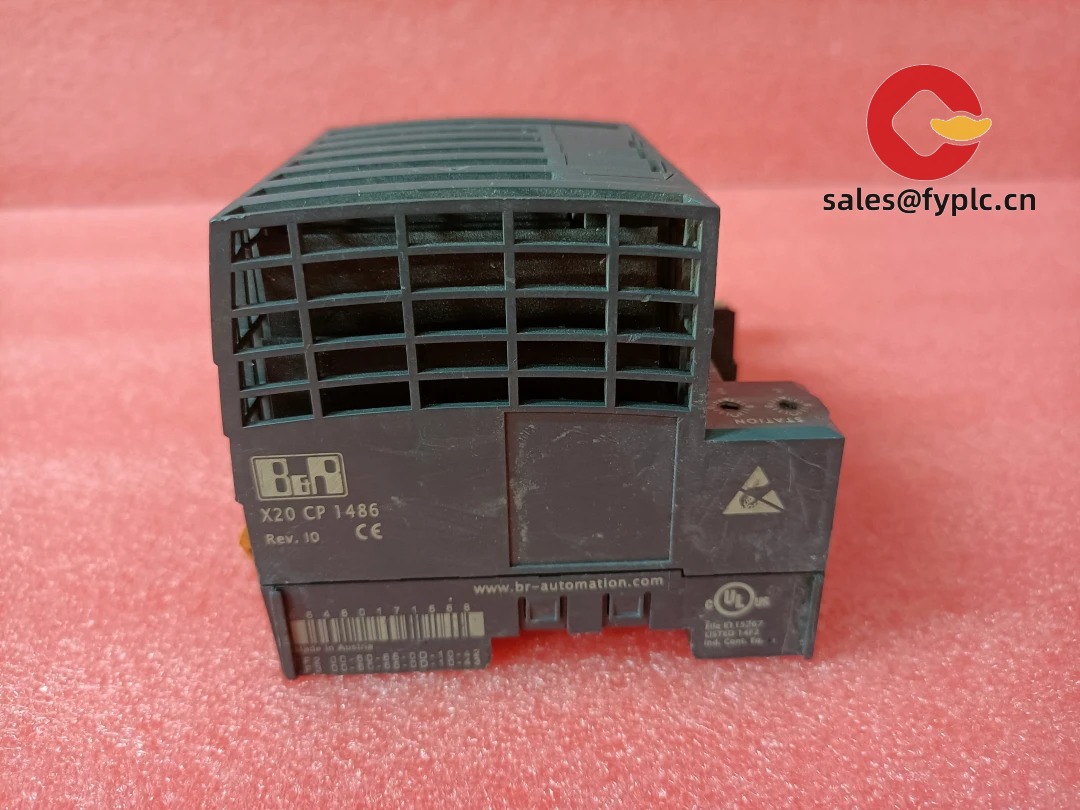

B&R X20CP1486 – Modular PLC CPU for high-speed machine control and POWERLINK-based motion

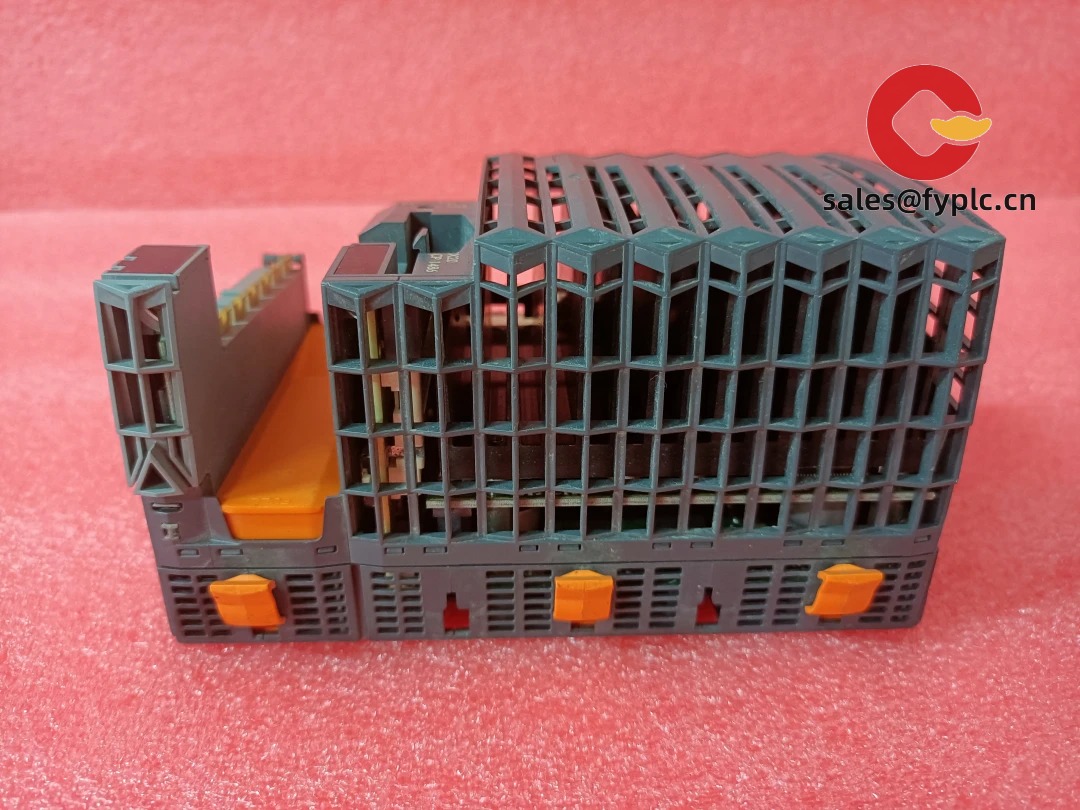

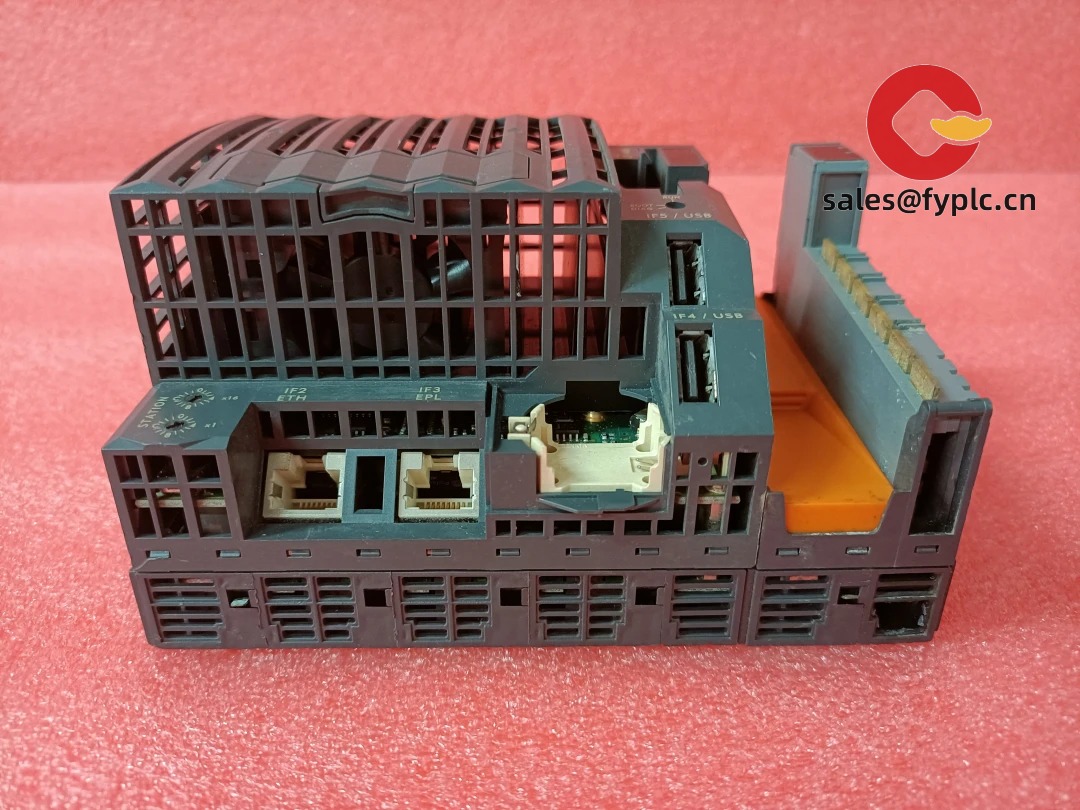

The B&R X20CP1486 is part of the X20 modular control platform, designed for compact, fast PLC control with real-time Ethernet. From my experience, it fits best where you need IEC 61131-3 logic, synchronized motion, and scalable I/O in one clean DIN-rail package. You might notice that it’s often the controller of choice in packaging, plastics, and material handling lines where POWERLINK and standard Ethernet coexist without drama.

One thing I appreciate is how quickly you can build a complete system around it: slide on the X20 I/O slices you need, add an interface module if you want serial or CAN, and you’re ready to deploy. A maintenance lead told us this model “just runs”—startup is quick, and the fanless design typically means fewer service calls.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Modular X20 architecture – Add digital/analog I/O, safety, and interface slices directly; keeps cabinets tidy and scalable.

- Real-time networking – Typically includes standard Ethernet plus POWERLINK for synchronized motion and deterministic control.

- Fanless, cabinet-friendly design – Robust, low-maintenance operation for 24/7 production environments.

- IEC 61131-3 control with motion – Seamless logic and motion task execution in Automation Runtime for machine builders.

- Service-friendly – USB service port and removable storage (on applicable variants) simplify commissioning and backups.

- Wide X20 ecosystem – Easy pairing with X20DI/DO/AI/AO, X20IF (serial/CAN), and POWERLINK drives.

Technical Specifications

| Brand / Model | B&R X20CP1486 |

| HS Code | 8537.10 (Programmable controllers) |

| Power Requirements | 24 VDC (typically 18–30 VDC); fanless, low power consumption |

| Dimensions & Weight | Approx. 99 × 72 × 62.5 mm (H × D × W), ~0.25 kg (typical for X20 CPU form factor) |

| Operating Temperature | Typically −25 to +60 °C (cabinet installation; actual limit depends on configuration) |

| Signal I/O Types | No onboard I/O; expandable via X20 I/O modules (digital, analog, safety, motion) |

| Communication Interfaces | Ethernet 10/100 (typically 2 ports with switch), POWERLINK (real-time), USB service; optional serial/CAN via X20IF modules; X2X Link for local/remote I/O |

| Protection / Mounting | IP20; DIN-rail mounting on X20 terminal base in control cabinet |

Application Fields

The X20CP1486 is widely used in:

- High-speed packaging machines with synchronized conveyors and servo axes over POWERLINK

- Plastics processing (extrusion, thermoforming) where consistent cycle times and reliable temperature loops matter

- Material handling and intralogistics – shuttle systems, sorters, and AS/RS with distributed I/O

- Food & beverage filling/labeling lines that need deterministic control and easy expansion

- General machinery retrofits replacing legacy PLCs while reusing existing field wiring

“We dropped the X20CP1486 into a compact cartoner and trimmed cabinet depth by almost 20% while keeping POWERLINK motion. Commissioning felt straightforward.”

Advantages & Value

- Reliability in harsh duty – Fanless and solid-state design reduces moving parts and unplanned stops.

- Compatibility – Works seamlessly with the full X20 I/O family and POWERLINK drives; standard Ethernet for MES/SCADA connectivity.

- Lifecycle savings – Modular I/O lets you scale channels without redesigning the cabinet; spares are easy to hold and swap.

- Engineering efficiency – Reusable function blocks in Automation Studio typically cut commissioning time.

- Supportability – Clear diagnostics and hot-swappable I/O slices minimize downtime during maintenance.

Installation & Maintenance

- Cabinet standards – Install on DIN rail inside an IP54+ control cabinet; allow vertical mounting with adequate clearance.

- Power & grounding – Use a regulated 24 VDC supply with proper PE bonding; separate clean 24 VDC logic from noisy loads when possible.

- Ventilation – Provide airflow to keep ambient within the specified temperature range; avoid heat sources directly below the CPU.

- Wiring – Use shielded twisted-pair for Ethernet/POWERLINK; route signal and power cables separately to reduce EMI.

- Routine maintenance – Periodic dust removal, check terminal tightness, verify firmware consistency, and back up application data after changes.

- Firmware & backups – Standardize firmware versions across lines; keep an image on removable media (where applicable) for quick swap-outs.

Quality & Certifications

- CE compliant for industrial environments

- UL/cUL listed (typical for B&R X20 system controllers)

- RoHS conformant

- Manufactured under ISO 9001 quality systems

- Manufacturer’s warranty: typically 12 months; our sales warranty period is 365 days

Commonly Paired X20 Modules

- X20DI/DO series – Discrete input/output slices for sensors, valves, and interlocks.

- X20AI/AO series – Analog modules for temperature, pressure, and drive reference signals.

- X20IF modules – Interface options (e.g., RS232/RS485/CAN) when additional serial or fieldbus links are needed.

- X20PS power modules – 24 VDC supply integration with status diagnostics.

Need help verifying your exact X20CP1486 interface set?

Interface availability can vary by configuration. Share your current part list or photos of the existing rack, and we’ll confirm compatibility and shipping options the same day.

Reviews

There are no reviews yet.