Description

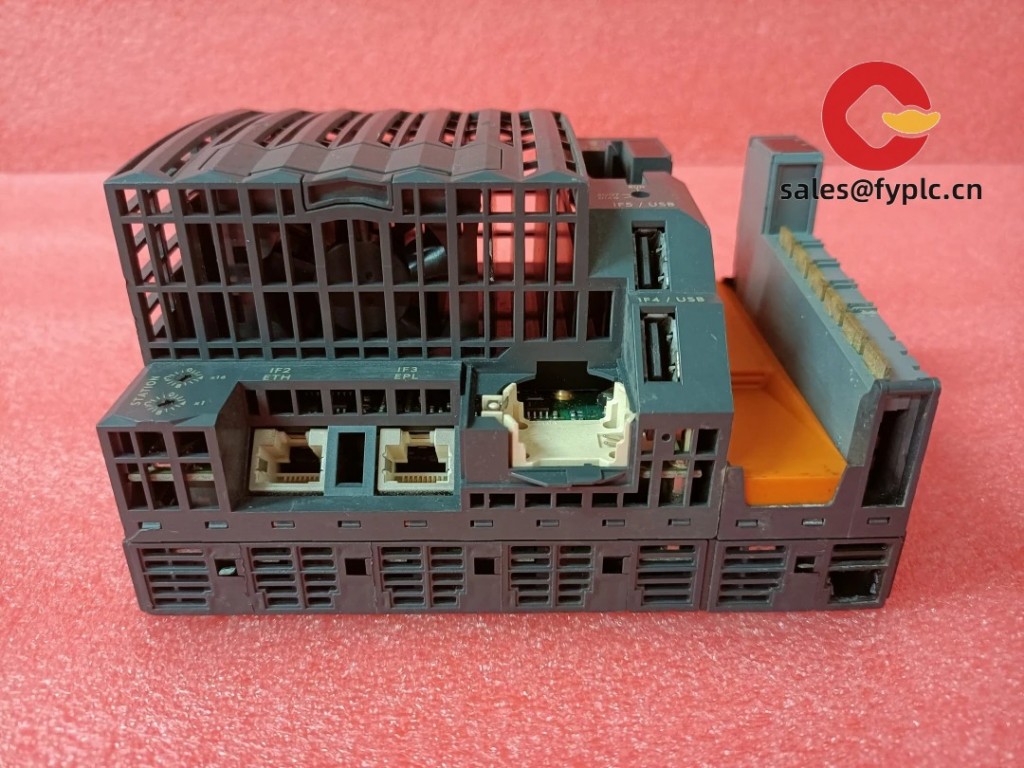

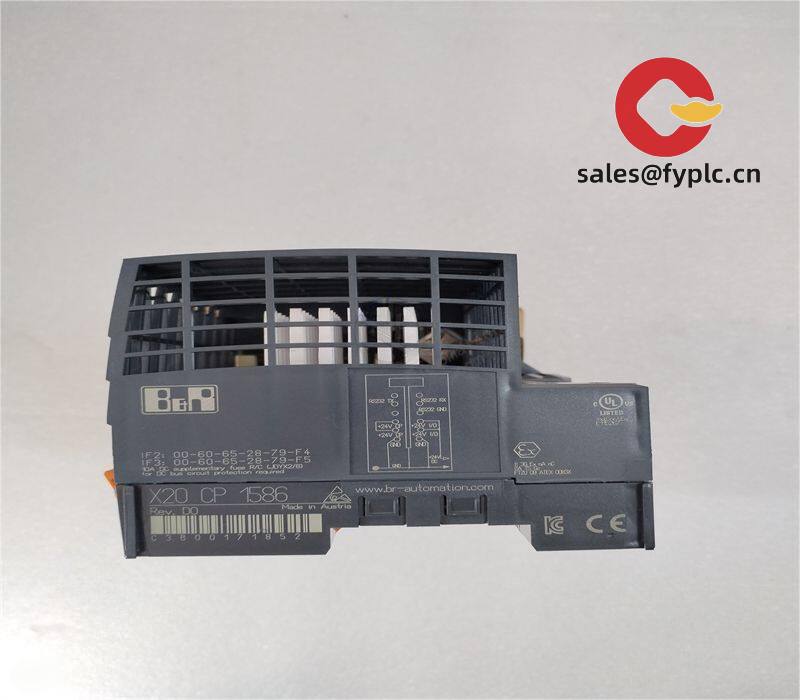

B&R X20CP1586 – Compact PLC CPU for high-performance modular machine control

The B&R X20CP1586 is a compact controller from the X20 series, built for fast, deterministic control in space‑constrained panels. From my experience, it’s a solid fit for packaging, assembly, and material handling machines where you want PC‑class performance but still rely on rock‑solid PLC behavior. You might notice that it integrates cleanly with the X20 I/O slices and common fieldbus options, so scaling the system up or down is typically straightforward.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Compact X20 CPU form factor – Saves panel space while keeping full controller functionality on DIN rail.

- Modular I/O expansion – Works natively with X20 digital/analog I/O slices; add only what you need.

- Industrial Ethernet connectivity – Typically includes Ethernet for programming, HMI, and plant networks.

- Service-friendly design – Front access to ports and status LEDs simplifies commissioning and maintenance.

- Deterministic control performance – Designed for fast machine cycles and coordinated motion in many cases.

- Flexible fieldbus options – POWERLINK, CAN, PROFIBUS, and others available via interface modules when required.

Technical Specifications

| Brand / Model | B&R X20CP1586 |

| HS Code | 8537.10 (Programmable controllers) |

| Power Requirements | 24 VDC via X20 system power module; typical consumption 5–8 W depending on configuration |

| Dimensions & Weight | Approx. 99 × 37.5 × 71.5 mm (H×W×D); around 0.13 kg |

| Operating Temperature | 0 to +55 °C (typical for this series; check exact variant and environment) |

| Signal I/O Types | No onboard I/O; supports modular X20 digital/analog I/O via backplane slices |

| Communication Interfaces | Ethernet (RJ45) for engineering/HMI; USB; serial service interface. Optional fieldbus via X20 interface modules (e.g., POWERLINK, CAN, PROFIBUS). |

| Installation Method | DIN rail (EN 60715) with X20 terminal base; side-by-side with I/O slices |

Application Fields

The X20CP1586 is commonly used in discrete manufacturing lines where fast PLC logic and modular I/O matter. Typical deployments include:

- Packaging machines and cartoners – quick cycle logic, motion coordination, and recipe handling.

- Assembly and test equipment – deterministic control with easy expansion of specialty I/O.

- Material handling and intralogistics – conveyor control, barcode/HMI connectivity over Ethernet.

- Process skids and utilities – integrates with fieldbus modules for pumps, valves, and instrumentation.

- Robotics cells – works as a cell controller with safety and motion handled via dedicated modules.

Advantages & Value for Procurement

- Reliable lifecycle and availability – The X20 platform is widely adopted; parts traceability and service typically straightforward.

- Modularity reduces TCO – Add only the I/O and interfaces you need; fewer spares and lower panel footprint.

- Compatibility – Seamless with X20 I/O, HMI panels, and common industrial networks, reducing integration risk.

- Engineering efficiency – Automation Studio support simplifies version control, diagnostics, and updates.

- Scalable performance – From small machines to multi-axis cells, you can reuse the same architecture.

A customer in food packaging told us they swapped an older rack PLC for the X20CP1586 and cut their panel width by roughly 25%, while keeping cycle times stable. That seems to be a common theme with this series.

Installation & Maintenance

- Panel and rail: Mount on EN 60715 DIN rail inside a ventilated cabinet. Keep clearance for front wiring and service ports.

- Power and grounding: Use a clean 24 VDC source via the X20 power module; bond PE properly to reduce EMI.

- Thermal considerations: Maintain ambient within 0–55 °C; avoid heat sources and ensure vertical airflow.

- Wiring: Separate signal and power wiring; use shielded cables for high‑speed comms and motion networks.

- Routine maintenance: Periodic dust cleaning, verify connector tightness, and back up project files after changes.

- Firmware and tools: Keep controller firmware and Automation Studio project versions aligned; update during planned downtime.

Quality & Certifications

- CE and UL/cUL compliance for industrial control equipment

- RoHS conformity

- Manufactured under ISO 9001 quality systems

- Manufacturer’s warranty typically 12 months; our supply warranty is 365 days

Helpful Accessories and Complementary Modules

- X20 terminal base and end cover – Required for proper DIN‑rail mounting and backplane connection.

- X20 power module (e.g., 24 VDC) – Feeds the CPU and attached I/O slices through the X20 bus.

- X20 interface modules – Add POWERLINK, CAN, or PROFIBUS where field integration is needed.

- X20 digital/analog I/O slices – Choose only the channel types and densities the machine actually needs.

Reviews

There are no reviews yet.