Description

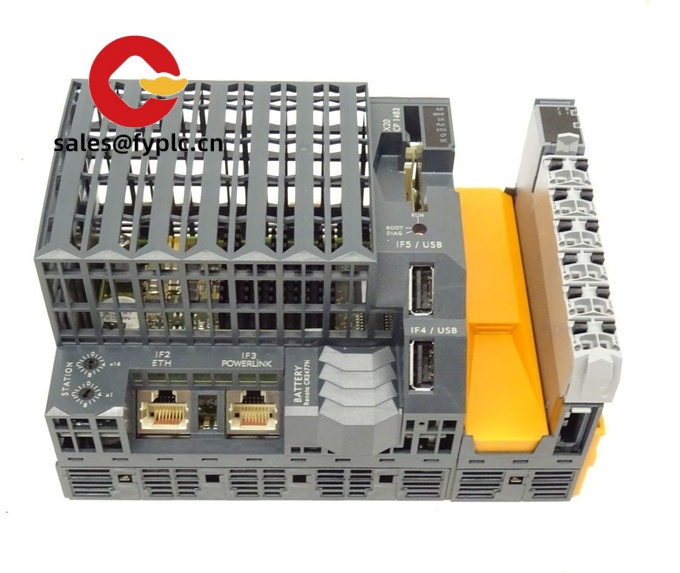

B&R X20CP1586 – Compact X20 CPU for high‑speed machine control and modular I/O

The B&R X20CP1586 is a modular PLC CPU for the X20 system, designed to drive fast, synchronized control tasks while keeping the footprint small. From my experience, it’s a solid fit for packaging machines, assembly cells, and compact lines where you want deterministic control, native X20 I/O expansion, and straightforward Ethernet connectivity—without the overhead of a PC-based controller.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Compact, modular CPU – Fits directly into the X20 backplane, keeping control and I/O in a single, tidy footprint on DIN rail.

- Deterministic control performance – Optimized for fast cyclic tasks and motion coordination on small to mid-sized machines.

- Integrated Ethernet for networking and service – Typical 10/100 Mbit/s Ethernet for programming, HMI, and line integration.

- USB service port – Convenient local service and firmware maintenance without extra adapters.

- Fieldbus flexibility – Expand with X20 interface modules to add POWERLINK, CAN, or other buses when required.

- No onboard I/O by design – Select only the X20 I/O modules you need (digital, analog, safety) and keep the system lean.

- Industry-ready build – Typically designed for 24 VDC control cabinets with good EMC resilience and solid temperature range for factory floors.

Technical Specifications

| Brand / Model | B&R X20CP1586 |

| Product Type | X20-series PLC CPU (controller module) |

| HS Code | 8537.10 (Programmable control panels for a voltage ≤ 1000 V) |

| Power Requirements | 24 VDC via X20 power module (typical, supplied through the X20 backplane) |

| Operating Temperature | Typically 0 to +55°C (cabinet-mounted; depends on installation and load) |

| Signal I/O | No onboard discrete/analog I/O; expandable with X20 I/O modules |

| Communication Interfaces | Integrated Ethernet (10/100 Mbit/s) and USB service; additional fieldbus via X20 interface modules |

| Installation Method | DIN-rail, mounted on X20 base modules within a control cabinet |

| System Compatibility | B&R X20 I/O and interface modules; Automation Studio engineering |

Where it fits best

You might notice that the X20CP1586 shines in machines that need tight loop times but not a full industrial PC. Typical use cases include:

- Pick-and-place cells with synchronized axes and compact HMIs

- Small packaging lines with distributed I/O and motion nodes

- Process skids where Ethernet integration and modular expansion are key

A maintenance lead from a food plant told us they swapped to X20CP1586 to standardize on X20 I/O and shorten changeover times—“we kept the same cabinet footprint and added POWERLINK later using an interface module when we upgraded the filler,” was the gist.

Related or Supporting Products

- X20PS2100 – 24 VDC power supply module for X20 systems; stable bus power for CPU and I/O.

- X20BM11 – X20 base module for CPU and I/O mounting; simplifies wiring and module replacement.

- X20IF10E1-1 – Ethernet interface expansion when additional network ports are needed.

- X20IF10A3-1 – POWERLINK interface for deterministic motion/drive networks.

- X20DI9371 / X20DO9322 – Popular digital input/output modules to tailor the I/O count.

- Comparable CPUs: X20CP1584 (similar class, different interface mix), X20CP1382 (cost-optimized option for lighter tasks). Interface counts and performance vary—ask which aligns with your cycle times.

Installation & Maintenance

- Cabinet & rail – Mount on DIN rail with X20 base modules; leave space for wiring bend radius and airflow. From my experience, a small top/bottom ventilation margin reduces thermal throttling in warm rooms.

- Power & grounding – 24 VDC clean supply; bond cabinet ground properly. Keep Ethernet and fieldbus away from motor cables; use shielded cables where recommended.

- Networking – Assign fixed IPs for controllers and HMIs; document addressing on the cabinet door. Many teams also segregate motion or safety networks on separate switches.

- Safety – De-energize before module changes. Validate E-stop circuits and safety I/O in accordance with your Performance Level or SIL targets.

- Routine maintenance – Back up the project from Automation Studio, check event logs monthly, clean dust filters, and schedule firmware updates during planned downtime. Replace worn DIN-rail springs if a panel sees frequent vibration.

Quality & Certifications

- CE, UL/cUL, and RoHS compliance for industrial control equipment (typical for the X20 family)

- Manufactured under ISO 9001 quality systems

- Manufacturer warranty applies; we provide a 365‑day supply warranty on deliveries

Reviews

There are no reviews yet.