Description

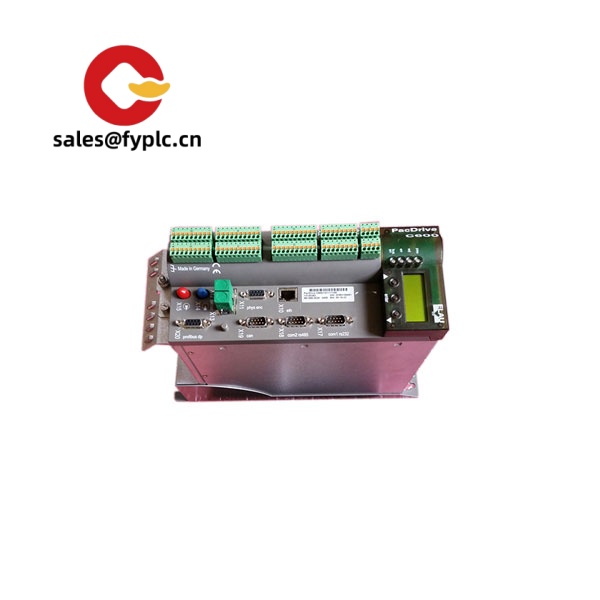

C1000100STD Industrial Control Module – Standard I/O interface for automation panels and PLC systems

The C1000100STD is a compact, standard I/O module designed for integrating field signals into existing PLC/SCADA architectures. It fits neatly on a DIN rail, runs on a 24 VDC supply, and typically handles common 24 V digital signals with industrial EMC immunity. One thing I appreciate is how straightforward the wiring usually is—clearly labeled terminals, a sensible layout, and enough isolation to keep noise out of your control cabinet. In many cases, it’s used to expand I/O without touching the main PLC CPU, which helps keep downtime to a minimum during upgrades.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days from delivery

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Pre‑shipment services: functional check, physical inspection, and packaging photos upon request

Key Features

- Standard 24 VDC operation – Typically powered from a regulated 24 VDC bus, making it easy to drop into most control cabinets.

- DIN‑rail friendly – Compact footprint for TS‑35 rails; you might notice the mounting latches make swap‑outs quick.

- Industrial I/O handling – Suited for 24 V digital inputs and outputs; in many cases available with transistor or relay output variants.

- Robust isolation – Galvanic isolation between field I/O and logic side helps reduce noise and ground loop issues.

- Open protocols – Commonly supports Modbus RTU (RS‑485) and, in some configurations, Modbus TCP for easy PLC/SCADA integration.

- Serviceable design – From my experience, field wiring can be landed with removable terminal blocks, which speeds maintenance.

Technical Specifications

| Model | C1000100STD (Standard I/O Module) |

| HS Code | 8537.10 (Boards, panels, consoles for electric control, ≤1000 V) |

| Power Requirements | 24 VDC nominal; typical consumption <10 W |

| Dimensions & Weight | Compact DIN‑rail footprint; typically <0.30 kg |

| Operating Temperature | -20 to +60 °C (typical industrial environment) |

| Signal Input/Output Types | 24 V digital inputs; transistor or relay digital outputs (varies by variant) |

| Communication Interfaces | RS‑485 (Modbus RTU); some versions support Ethernet (Modbus TCP) |

| Installation Method | DIN‑rail (EN 60715) or panel mount with screws |

| Isolation & Protection | Channel‑to‑logic isolation and surge suppression on I/O (typical) |

Application Fields

This model is typically chosen for discrete automation tasks where reliable 24 V I/O is needed:

- Packaging and material handling lines (photoeyes, limit switches, solenoids)

- Process skids and OEM machinery needing quick I/O expansion

- Retrofit projects adding alarms, interlocks, or counters to existing PLCs

- Utilities and building services (pumps, fans, dampers, safety interlocks)

Quick example from a customer: a beverage plant dropped in the C1000100STD to expand 16 digital inputs and 8 outputs without re‑writing their main PLC logic. Downtime stayed under 90 minutes, and diagnostics through Modbus RTU made commissioning smoother than expected.

Advantages & Value

- Reliability – Industrial‑grade power and isolation design helps reduce nuisance trips and field noise issues.

- Compatibility – Modbus support typically allows pairing with Siemens, Schneider, Allen‑Bradley (via gateways), Emerson, and others.

- Cost efficiency – Expand I/O where it’s needed; no need to change a working PLC CPU.

- Service & supply – We stage units for quick dispatch and can pre‑configure addressing on request.

Installation & Maintenance

- Mounting: Install on TS‑35 DIN rail in a clean, dry control cabinet; allow 25 mm clearance for ventilation.

- Power: Use a regulated 24 VDC supply with proper grounding; separate noisy loads (VFDs/solenoids) from logic power where possible.

- Wiring: Use ferruled conductors; shield and ground RS‑485 at one end; keep signal and power cabling segregated.

- Safety: De‑energize before service; confirm polarity on I/O commons; follow local electrical codes.

- Routine care: Inspect terminals quarterly, clean dust, and verify I/O status LEDs. Firmware updates, if applicable, should be performed during scheduled downtime.

Quality & Certifications

- CE conformity for EMC and Low Voltage (typical for this class of module)

- RoHS compliance for restricted substances

- Manufacturer’s warranty: 12 months (365 days)

- Production and testing typically aligned with ISO 9001 quality systems

Supporting Components You May Need

- 24 VDC DIN‑rail power supply (60–100 W, depending on I/O load)

- TS‑35 DIN rail and end clamps

- Shielded RS‑485 cable and an unmanaged industrial Ethernet switch (if using Modbus TCP)

- Appropriate fusing or circuit breakers for field circuits

- Removable terminal blocks and ferrules for tidy wiring

If you’re matching an existing installation, share your current protocol, I/O mix (DI/DO), and enclosure temperature. From my experience, a quick check upfront avoids surprises and keeps commissioning smooth.

Reviews

There are no reviews yet.