Description

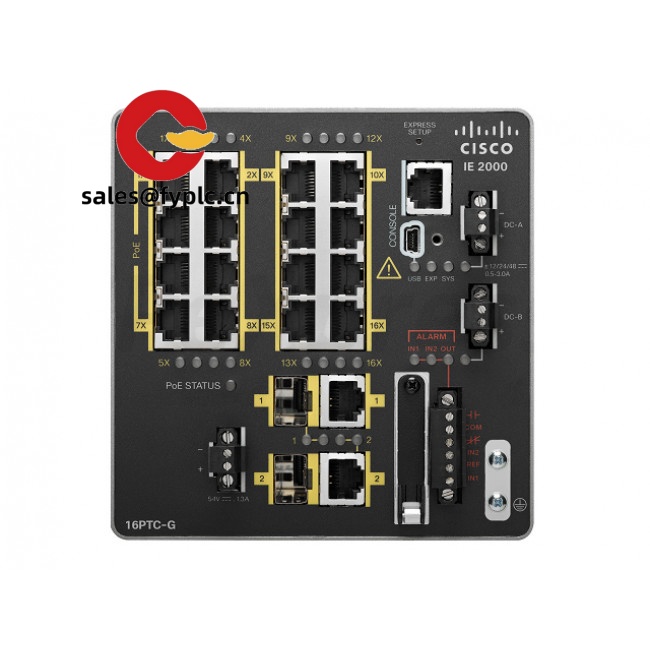

Cisco IE-2000-16TC-G-N — Rugged Industrial Ethernet Switch with Gigabit Uplinks for Factory and Outdoor Cabinets

The Cisco IE-2000-16TC-G-N is part of Cisco’s proven Industrial Ethernet 2000 Series. From my experience, it fits best where you need reliable Layer 2 switching at the edge—production lines, substations, roadside cabinets—without the noise and complexity of data-center gear. You get 16 Fast Ethernet copper ports for local devices and dedicated Gigabit SFP uplinks to backhaul traffic to your core. It’s fanless, DIN-rail friendly, and built to stay stable in temperature swings and electrical noise that typically knock consumer switches offline.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment for delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- 16x 10/100Base‑TX ports – Connect PLCs, drives, HMIs, cameras, and panel PCs without extra media converters.

- Gigabit SFP uplinks – The “G” variant provides 1G optical uplinks for clean, long-distance backhaul to your aggregation switch.

- Ruggedized design – Typically operates from -40 to +75°C with fanless cooling, helping stability in harsh cabinets.

- Dual DC power inputs – Redundant 24 VDC (wide range) input design to keep the switch alive during a supply drop.

- Industrial redundancy – Supports Cisco REP and standard RSTP/MSTP for fast ring recovery in most cases.

- Traffic control and segmentation – IEEE 802.1Q VLANs, QoS, IGMP Snooping for multicast, and storm control to contain broadcast bursts.

- Security hardening – 802.1X authentication, TACACS+/RADIUS, SSH/HTTPS management, plus port security to reduce unauthorized access.

- Alarm relay and status – You might notice the dry-contact relay helps integrate switch health into your PLC/SCADA alarming.

- Simple deployment – DIN-rail mounting, front-facing terminals, and Cisco IOS management (CLI, SNMP) shorten commissioning time.

Technical Specifications

| Brand / Model | Cisco IE-2000-16TC-G-N (Industrial Ethernet Switch) |

| HS Code | 8517.62.00 (Switching and routing apparatus) |

| Power Requirements | Dual redundant DC input, 24 VDC nominal (typically 18–60 VDC range); fanless |

| Operating Temperature | -40 to +75 °C (industrial extended temp) |

| Signal I/O Types | 16x 10/100Base‑TX (RJ‑45), 2x 1G SFP uplinks; 1x alarm relay (dry contact) |

| Communication Interfaces | Ethernet; management via Cisco IOS (CLI), SNMP, HTTPS/SSH; supports VLAN, QoS, IGMP Snooping, RSTP/MSTP, Cisco REP |

| Installation Method | DIN‑rail (standard), panel mounting available; front-facing power and alarm terminals |

| Protection / Enclosure | IP30 metal enclosure; fanless convection cooling |

A quick real-world example: a bottling line engineer told us they swapped an office-grade switch for this model and immediately stabilized camera streams and PLC updates. Ring failover with REP was under a second in their test, which seems to be more than enough for their SCADA polling cycle.

Related or Supporting Products

- Cisco IE-2000-8TC-G-* – Smaller 8-port variant with Gigabit SFP uplinks; ideal when cabinet space is tight.

- Cisco IE-2000-16PTC-G-* – Similar port count but with PoE/PoE+ on copper ports to power IP cameras or wireless APs.

- Cisco GLC-SX-MM / GLC-LH-SM SFPs – Multimode and single-mode 1G SFP transceivers for uplink flexibility.

- Cisco PWR-IE50W-AC-DC= / PWR-IE170W-AC-DC= – DIN-rail AC‑to‑DC power supplies commonly paired with IE switches.

- DIN-rail fiber patch cords and LC SFP pigtails – To keep optical uplinks clean and serviceable in the cabinet.

Installation & Maintenance

- Cabinet and environment – Use a sealed control cabinet (IP54 or better) with DIN-rail; allow vertical airflow around the chassis. Keep ambient within -40 to +75°C and humidity non-condensing.

- Power and grounding – Feed from a SELV/PELV 24 VDC source; wire dual inputs for redundancy. Bond protective earth to the chassis ground stud to reduce EMC issues.

- Wiring practice – Use industrial-grade shielded Ethernet where noise is present. Separate power, signal, and Ethernet paths; observe minimum bend radius for fiber SFP links.

- Network design – For rings, enable REP or RSTP/MSTP; segment OT traffic with VLANs; apply IGMP Snooping for multicast drives or vision streams.

- Routine maintenance – Periodically check terminal torque, clean dust with dry air, and back up the running-config. Plan IOS firmware updates during scheduled downtime after validating release notes.

- Safety – De-energize before wiring. Verify SFP module compatibility and optical budgets if links exceed typical distances.

Quality & Certifications

- Conformity typically includes CE, UL/CSA (industrial control equipment), and RoHS.

- Designed for industrial EMC; fanless IP30 enclosure for cabinet use.

- Cisco limited hardware warranty applies per Cisco policy; coverage terms may vary by region and model.

If you’re consolidating panel switches or standardizing on a rugged platform, this model usually hits a sweet spot—enough copper for local IO networks, fiber uplinks for distance, and simple, dependable redundancy. Let me know the number of cabinets, fiber type (SM/MM), and whether PoE is needed; I can tailor a parts list with SFPs and power supplies that just works.

Reviews

There are no reviews yet.