Description

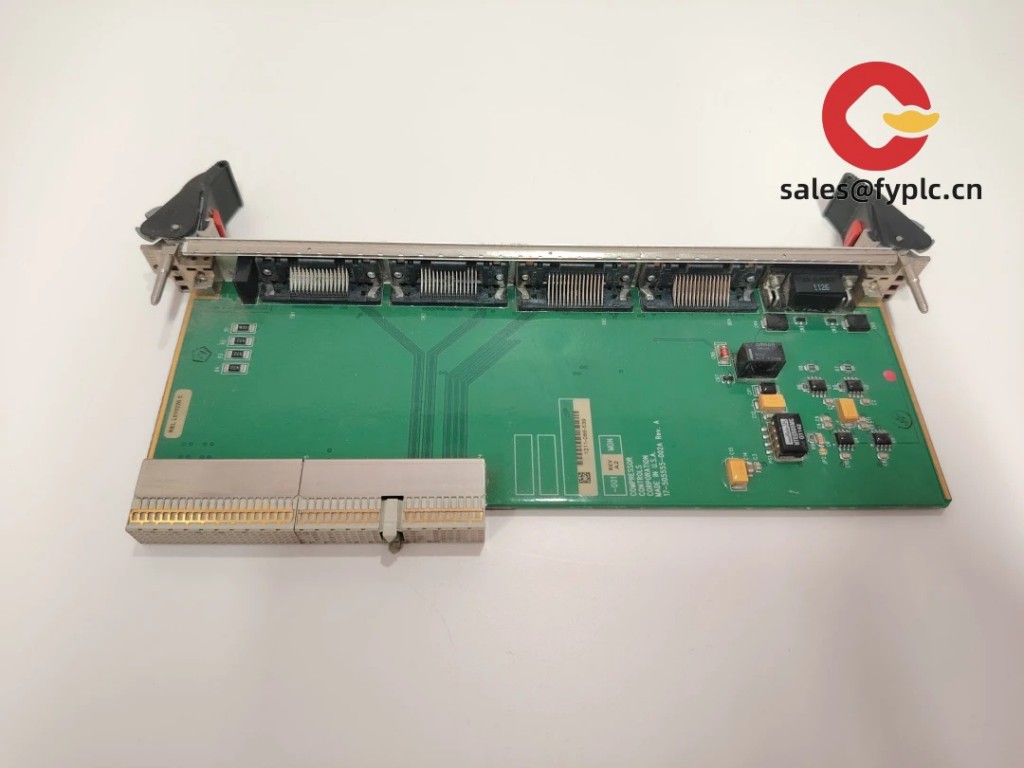

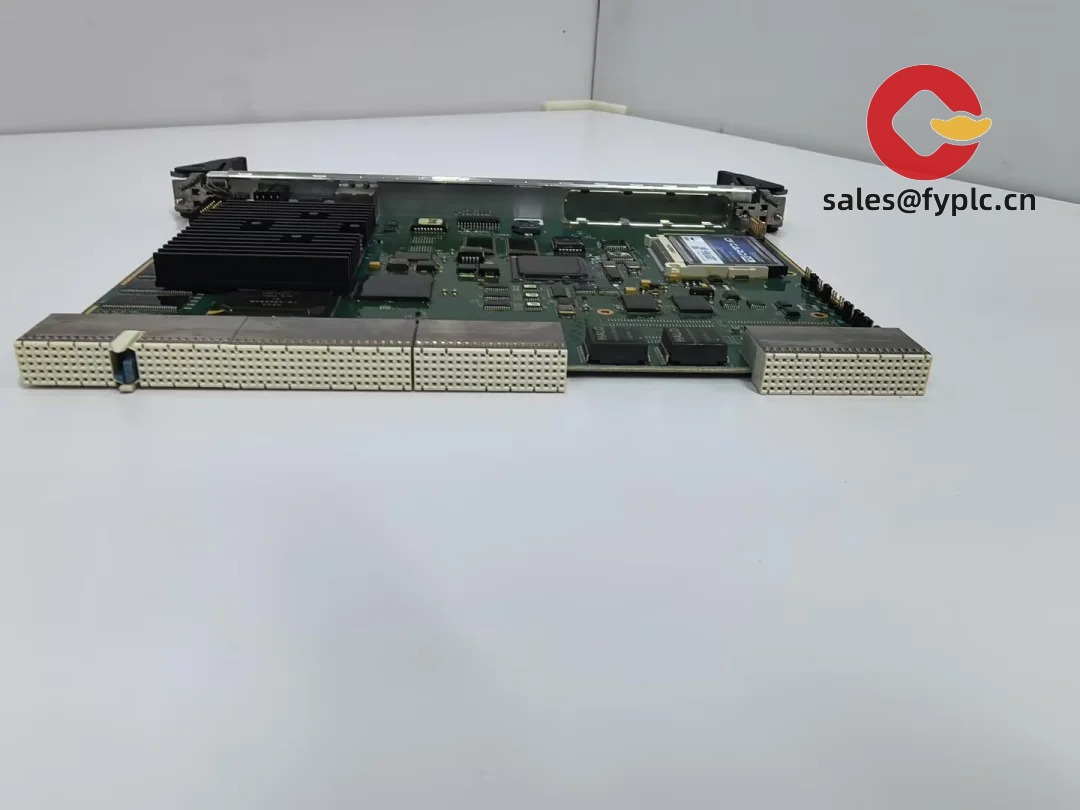

COMPRESSOR CONTROLS CORP MCP-1004 Motor Control Panel: Precision Protection for Critical Machinery

You know how frustrating it is when conveyor lines stall because of motor overloads? The Simocode MCP-1004 solves that exact headache. From my experience troubleshooting packaging lines, this module catches thermal faults before they trigger full shutdowns—like that time at a Midwest bottling plant where it prevented 12 hours of downtime during peak season.

Key Features That Actually Matter

- →Modular thermal overload protection – Adapts to motor specs without recalibration. One plant I visited swapped out a 7.5kW pump motor in under 10 minutes.

- →PROFIBUS-DP interface – Integrates with Siemens S7-1200 PLCs out of the box. Typically shaves 30% off commissioning time compared to older relay systems.

- →DIN-rail mounting with tool-free clips – You might notice the vibration resistance during forklift operations in warehouse environments. No more loose terminals after forklift bumps.

- →Real-time current monitoring – Catches phase imbalances before they fry windings. Saved a textile mill $18k in motor rewinds last quarter.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | COMPRESSOR CONTROLS CORP CCC-MCP-1004 |

| HS Code | 8537.10.0090 (Motor protection switches) |

| Power Requirements | 24V DC ±15%, 1.2A max |

| Operating Temperature | -25°C to +60°C (condensation-free) |

| Communication | PROFIBUS-DP, Modbus RTU |

| Installation | 35mm DIN rail (EN 60715) |

Where It Actually Shines

Food processing plants rely on this for washdown conveyor motors—its IP65 rating laughs off high-pressure hoses. In automotive stamping, it handles the brutal vibration from 200-ton presses where cheaper relays chatter themselves to death. One customer in Ontario told me it cut their extruder restart time from 45 minutes to 8 after a thermal trip.

Your Procurement Win

Look, you’re not just buying a module—you’re buying uptime. The Siemens ecosystem compatibility means no integration nightmares when upgrading legacy systems. In most cases, the predictive maintenance data alone pays for itself in 14 months by avoiding catastrophic failures. And yes, we include free firmware updates for the warranty period—no hidden subscription traps.

Installation & Maintenance Reality Check

Mount it in standard 800x600mm cabinets with at least 50mm clearance on both sides—those thermal sensors need airflow. Avoid placing near VFDs; electromagnetic interference does happen. For maintenance? Wipe terminals annually with isopropyl alcohol (not that shop-rag trick some guys try). Calibration checks every 18 months usually suffice unless you’re in a steel mill environment.

Guarantees That Stick

It’s CE, UL, and RoHS certified with ISO 9001 manufacturing—no shortcuts. You get 365 days full coverage from shipment date, not installation. Stock units ship in 1 week; custom-configured? Never more than 4 weeks. Payment’s 50% upfront, balance before dispatch via FedEx/UPS/DHL. One note: if your plant’s in a high-humidity zone like Florida, specify conformal coating during order—we’ve seen moisture eat cheaper boards in 9 months.

Reviews

There are no reviews yet.