Description

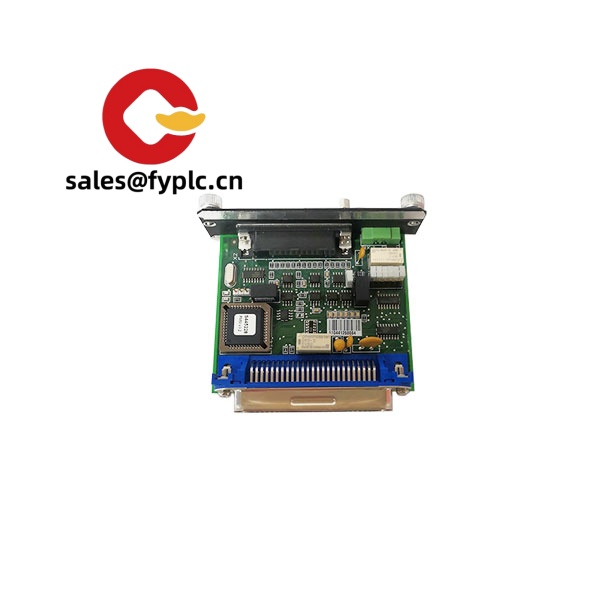

DAEWOO DASD-CT15SPXB Servo Drive Module for CNC Axis/Spindle Control

The DAEWOO DASD-CT15SPXB is a servo drive module used on many legacy Daewoo/Doosan CNC machines for axis or spindle regulation. From my experience, it’s typically installed as a drop-in amplifier within the machine’s electrical cabinet, handling closed-loop speed and torque control with stable performance. You might notice that it pairs well with existing motors and feedback cabling on Daewoo-built equipment, which saves both time and integration cost during maintenance.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock items; no more than 1 month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express Options: FedEx, UPS, DHL

Key Features

- Closed-loop control – Stable speed/torque regulation with encoder feedback for consistent machining quality.

- Drop-in replacement – Designed to fit existing Daewoo/Doosan cabinets and harnesses, reducing retrofit time.

- Versatile command types – Typically supports analog ±10 V speed/torque command and standard digital I/O for enable/alarms; many cases also accept pulse train input.

- Protection functions – Over-current, over-voltage, regen and thermal protections help safeguard the machine and the drive.

- Serviceability – Parameter backup/restore and straightforward terminal access simplify field maintenance.

- Cabinet-friendly cooling – Forced-air design intended for panel mounting with top/bottom airflow clearance.

Technical Specifications

| Brand / Model | DAEWOO DASD-CT15SPXB |

| HS Code | 8504.40 (Static converters – AC motor/servo drives) |

| Power Requirements | 3‑phase AC, voltage class varies by unit; commonly 200–230 VAC or 380–480 VAC variants |

| Operating Temperature | 0–40°C typical cabinet environment (non‑condensing humidity) |

| Signal I/O Types | Analog ±10 V command, digital I/O (enable, fault, ready); encoder feedback (incremental), model‑dependent |

| Communication Interfaces | Proprietary drive/CNC bus; service/maintenance port on some builds (confirm on nameplate) |

| Installation Method | Panel/cabinet mount with screw slots; forced‑air cooling; allow vertical clearance |

| Protection Rating | Typically IP20 open-chassis inside control cabinet |

Note: Specific voltage class, I/O mapping, and connector layouts can vary by machine build. It’s best to verify against your existing unit label.

Application Fields

- CNC machining centers and lathes originally built by Daewoo/Doosan.

- Gantry loaders, transfer lines, and retrofit projects needing a like-for-like Daewoo servo amplifier.

- Axis or spindle regulation in legacy equipment where the exact part number is required to avoid requalification.

Advantages & Value

- Reduced downtime – A direct replacement minimizes machine re-commissioning and keeps production on schedule.

- Compatibility – Works with existing motors, encoders, and harnessing in most cases, avoiding costly re-cabling.

- Predictable cost – No need to redesign the axis/spindle loop, which typically lowers total maintenance spend.

- Support – We can share wiring cross-checks, basic parameter notes, and start-up tips for faster commissioning.

One thing I appreciate is how forgiving this drive tends to be during parameter restoration. Technicians often mention that copying the key tuning and motor constants from the old unit gets them cutting parts again the same shift.

Installation & Maintenance

- Cabinet environment – Mount in a sealed control cabinet (IEC/NEMA), keep ambient ≤ 40°C, and allow 50–100 mm clearance above and below the drive for airflow.

- Power and grounding – Match the unit’s voltage class before energizing; use proper PE grounding, shielded motor/encoder cables, and a clean star-ground scheme.

- Braking & line conditioning – Size the external braking resistor appropriately; consider line reactor/EMC filter if harmonics or noise are present.

- Parameter handling – Back up parameters from the old drive when possible; restore and verify motor constants, encoder counts, and polarity before enabling.

- Routine care – Quarterly dust removal, check fan operation, and re-torque power terminals; visually inspect capacitors and connectors for heat discoloration.

- Safety – Lockout/tagout, discharge DC bus before service, and confirm motor insulation health with proper testing (motor side) prior to final tuning.

Quality & Certifications

- Manufacturer’s quality standards for industrial servo drives; typical CE compliance on production units.

- UL/cUL marking may apply depending on production batch; RoHS status can vary with revision.

- Warranty coverage: 365 days from shipment.

Recommended Supporting Components

- Matched servo motor with compatible encoder (as per the existing Daewoo/Doosan machine spec).

- External braking resistor sized to duty cycle and inertia.

- Line reactor or EMC filter for mains conditioning in noisy plants.

- Shielded encoder and motor power cables with proper grounding hardware.

If you can share a photo of your current nameplate or the machine model/axis label, we can confirm the voltage class, connector layout, and any parameter notes specific to your DASD-CT15SPXB. That small step usually speeds up replacement and avoids guesswork on power and I/O.

Reviews

There are no reviews yet.