Description

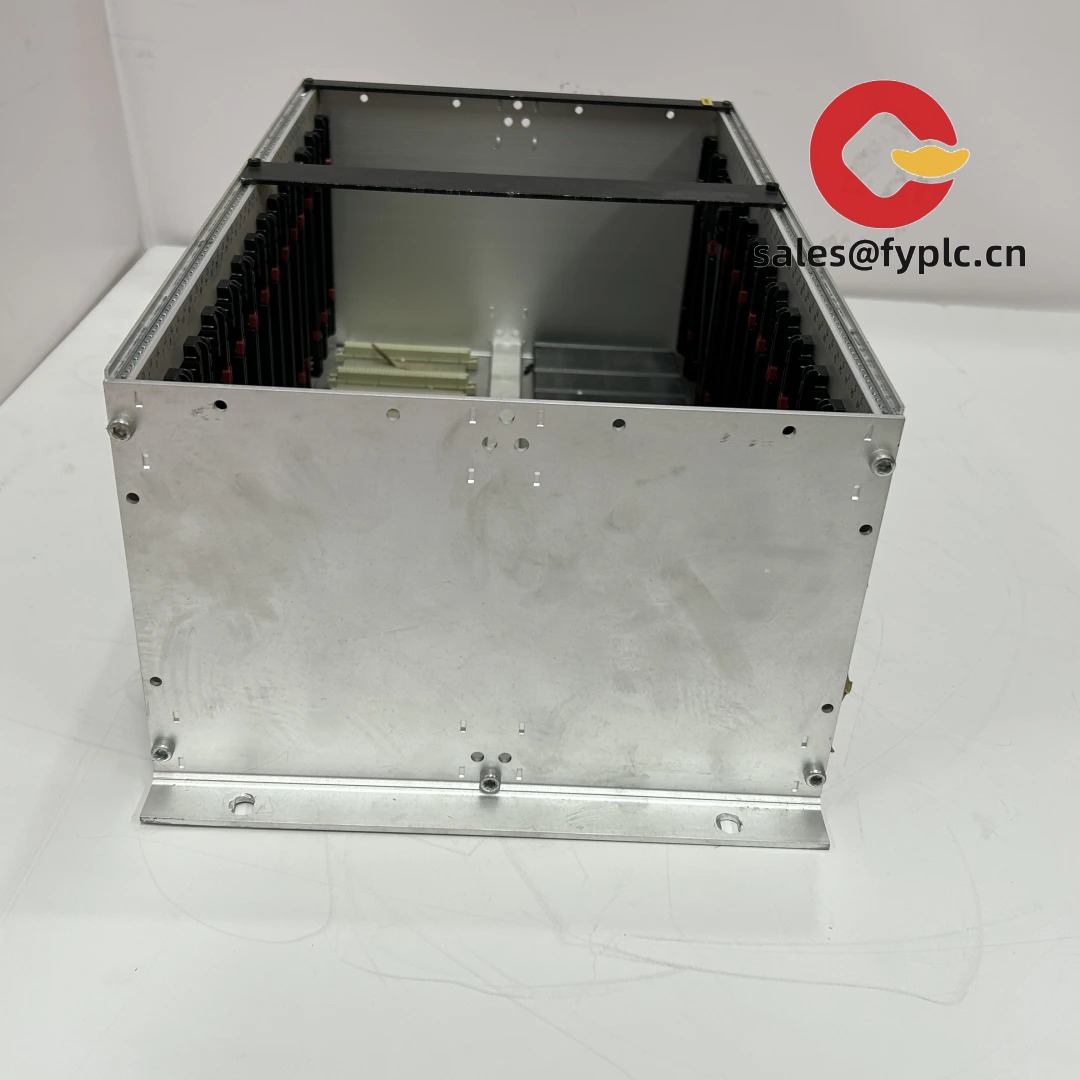

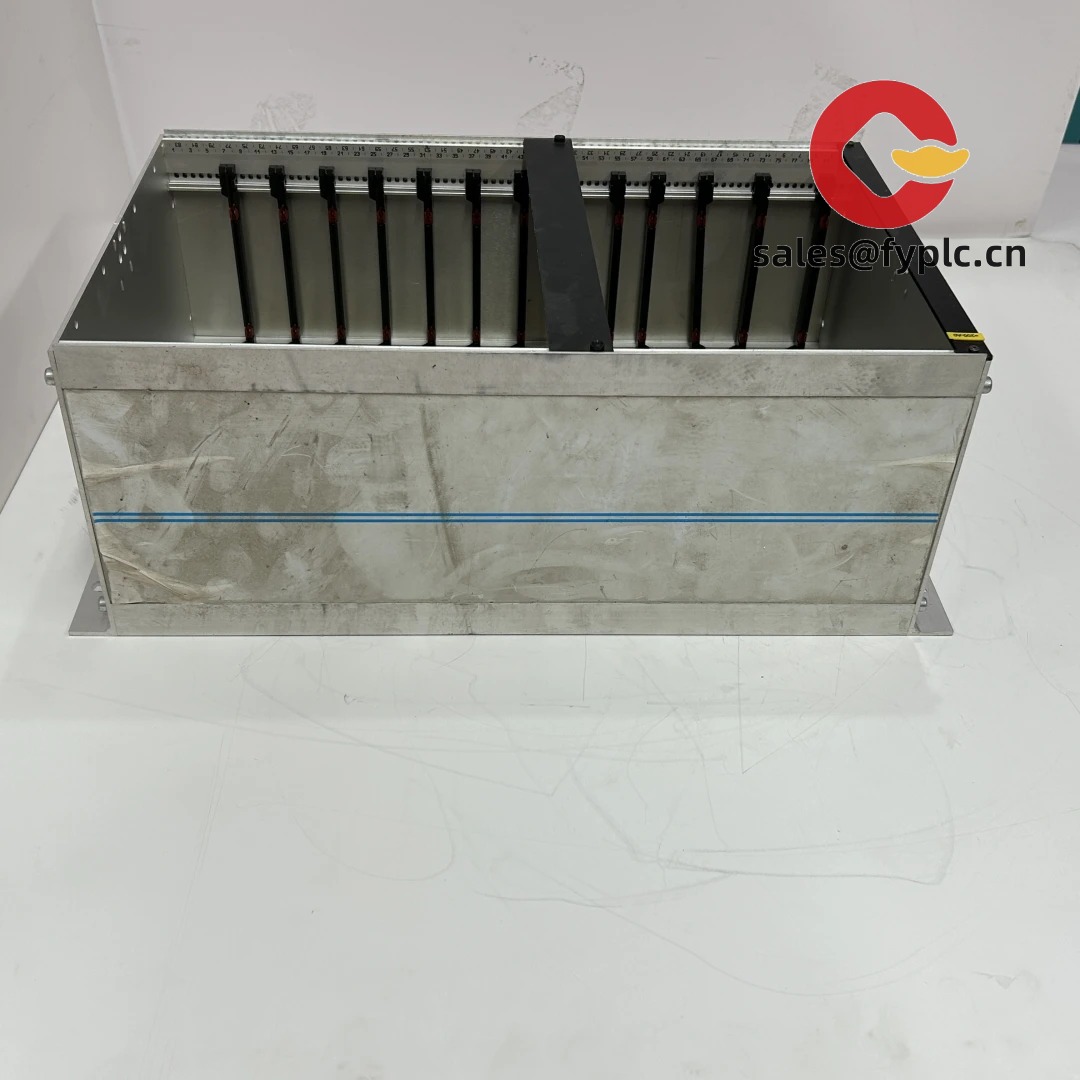

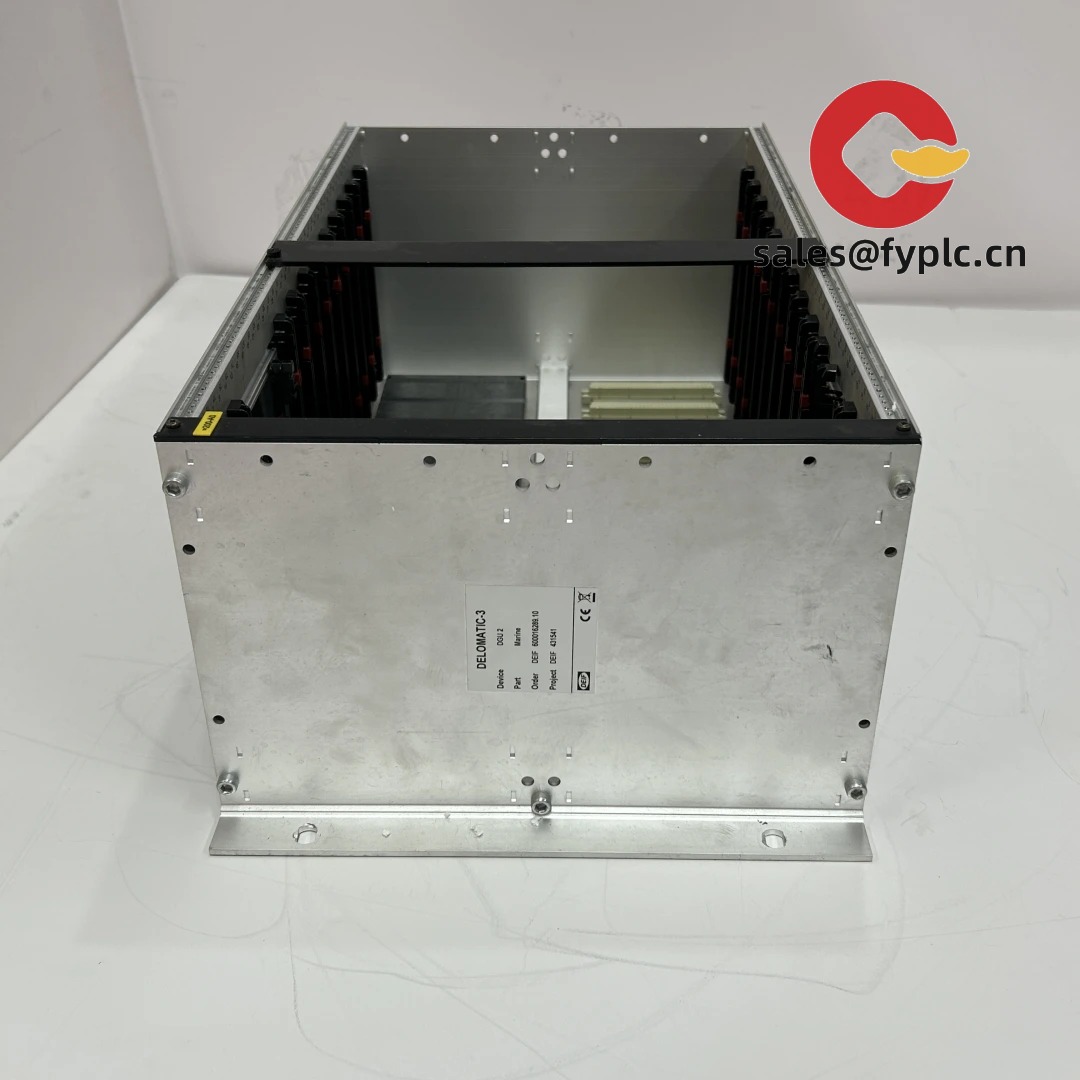

DEIF DELOMATIC-3 Printed Circuit Board – OEM spare board for marine power management and genset control

The DEIF DELOMATIC-3 Printed Circuit Board is an original replacement board for DEIF’s DELOMATIC-3 power management system, widely used on vessels and offshore platforms. From my experience, this is the part you fit when you need your switchboard to behave exactly like it did before—same firmware family, same signal handling, no surprises for the chief engineer. It seems to be the most straightforward way to restore functions like load sharing, generator protection, breaker interlocks, or measurement acquisition without redesigning your panel.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment, full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- OEM compatibility with DELOMATIC-3 racks – Plug-in form factor and backplane edge connector match existing DELOMATIC-3 positions, so wiring and terminal numbering typically remain unchanged.

- Marine-grade design – Built for switchboard environments with vibration, humidity, and electrical noise commonly found on vessels and rigs.

- Signal fidelity – Maintains the original measurement scaling and protection logic, helping avoid re-parameterization in many cases.

- Integrated system bus – Works with the DELOMATIC-3 internal bus for inter-module communication and coordinated PMS functions (load sharing, load shedding, blackout recovery).

- Service-friendly replacement – You might notice that most boards can be swapped with standard ESD precautions and routine commissioning checks—no cabinet rebuild.

- Lifecycle support – A practical way to extend the life of legacy DELOMATIC-3 installations without moving to a new platform immediately.

Technical Specifications

| Brand / Model | DEIF DELOMATIC-3 Printed Circuit Board (OEM spare for DELOMATIC-3 PMS) |

| HS Code | 8538.90 (Parts for the apparatus of heading 8537 – control/switchgear parts) |

| Power Requirements | Backplane supplied, nominal 24 V DC (typical operating window 18–32 V DC) |

| Dimensions & Weight | Plug-in board for DELOMATIC-3 rack; weight typically < 0.6 kg (varies by board function) |

| Operating Temperature | Typically −20 to +55 °C in marine switchboards |

| Signal Input/Output Types | Depends on board type; commonly includes isolated 24 V DC digital inputs, relay outputs, analog I/O (4–20 mA / 0–10 V), and generator measurement via CT/PT interfaces |

| Communication Interfaces | DELOMATIC-3 internal bus; RS‑485 (Modbus RTU) and/or CAN on specific board variants |

| Installation Method | Plug-in card to DELOMATIC-3 rack/backplane inside marine switchboard; front-panel access for service |

Application Fields

The DELOMATIC-3 PCB is typically used where a legacy DEIF PMS is already installed:

- Commercial vessels (bulk carriers, RoRo, ferries) for load sharing, breaker control, and blackout recovery

- Offshore platforms and barges managing multiple diesel or dual-fuel gensets

- Naval or coastguard fleets maintaining standardized switchboard automation

- Industrial power plants that adopted DELOMATIC-3 in earlier projects and require lifecycle spare parts

Advantages & Value

- Reliability you can quantify – OEM boards preserve existing setpoints and logic, reducing re-commissioning time and the risk of nuisance trips.

- Cost control – Swapping a single card is usually far cheaper than migrating the whole PMS to a new platform.

- Compatibility – Interfaces align with the original DELOMATIC-3 wiring and CT/PT ratios, which avoids rework on the switchboard.

- Service support – From my experience, engineers appreciate that fault-finding remains the same—same LEDs, same test points, same parameters.

Feedback from a chief engineer on a North Sea RoRo: “We replaced the I/O board and were back on auto load sharing after a single harbor test. No rewiring, no extra drawings.”

Installation & Maintenance

- Cabinet & environment – Mount in a marine-grade switchboard with adequate ventilation; keep ambient typically within −20…+55 °C and avoid salt mist ingress.

- Power & wiring – Verify 24 V DC supply stability and polarity on the backplane. Use shielded cables for RS‑485 and measurement circuits; bond shields at one end to reduce noise.

- Safety – Isolate the cabinet, discharge stored energy, and observe ESD protection (wrist strap, antistatic mat) before handling the board.

- Commissioning – After replacement, check module addressing, verify parameter set/load sharing droop, and test breaker commands with interlocks in place.

- Routine maintenance – Inspect connectors annually for oxidation, gently clean with approved electronics cleaner, and back up parameters. Firmware updates, where applicable, should match your existing system revision.

Quality & Certifications

- Standards & approvals – Supplied as an OEM spare for DEIF DELOMATIC-3 systems used on classed vessels; systems are commonly installed under marine approvals such as DNV, ABS, or LR when commissioned as part of the full panel.

- EMC & safety – Designed for industrial/marine switchboard environments; compliance is typically inherited within the certified system.

- Warranty – 12 months (365 days) against defects in materials and workmanship.

Common Supporting Components (available on request)

- DELOMATIC-3 backplane/rack hardware and front panel accessories

- Measurement transducers (CTs/PTs) matched to DELOMATIC-3 scaling

- RS‑485 isolators, marine-grade power supplies (24 V DC), and relay interface modules

- Replacement terminal blocks, harnesses, and documentation kits for legacy panels

If you can share the board position or part code within your DELOMATIC-3 rack (e.g., I/O, measurement, or breaker command module), we’ll match the exact variant and confirm compatibility including firmware revision, connectors, and any field-replaceable fuses or relays.

Reviews

There are no reviews yet.