Description

DEIF IPM-1 Intelligent Power Manager – Centralised control for multi-source power systems

The DEIF IPM-1 is an Intelligent Power Manager designed to coordinate multiple power sources—diesel/gas gensets, utility mains, and energy storage—in a single, coherent control strategy. From my experience, teams choose IPM-1 when they want automatic load sharing, breaker logic, and import/export control without stitching together a dozen separate relays. You might notice that it slots naturally into DEIF ecosystems (AGC series controllers), but it also plays nicely with third-party PLC/SCADA via Modbus in many cases.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Automatic power management – Balances load across gensets, manages import/export with mains, and maintains spinning reserve where required.

- Breaker supervision & sequencing – Coordinates generator, bus-tie, and mains breakers with synch check and permissives for safe switching.

- Load sharing and droop/isochronous support – Works with DEIF genset controllers for kW/kvar sharing; helps reduce fuel burn and mechanical stress.

- Black start & load shedding – Restores power after a blackout and sheds non-critical loads automatically when capacity drops.

- Peak shaving & demand control – Limits utility import by bringing gensets online during demand spikes; often slashes demand charges.

- Scalable architecture – Typically supports multi-bus, multi-source topologies; straightforward expansion as plants grow.

- Open communications – Modbus connectivity for PLC/SCADA; coordination with DEIF AGC controllers over CAN/Ethernet is common.

- Event logging & alarms – Aids troubleshooting with timestamps for breaker events, load steps, and interlock states.

Technical Specifications

| Brand / Model | DEIF IPM-1 Intelligent Power Manager |

| HS Code | 8537.10 (Boards/panels for electric control or distribution) |

| Power Requirements | 24 VDC nominal (typically 18–32 VDC) |

| Operating Temperature | -20 to +70 °C (industrial environment) |

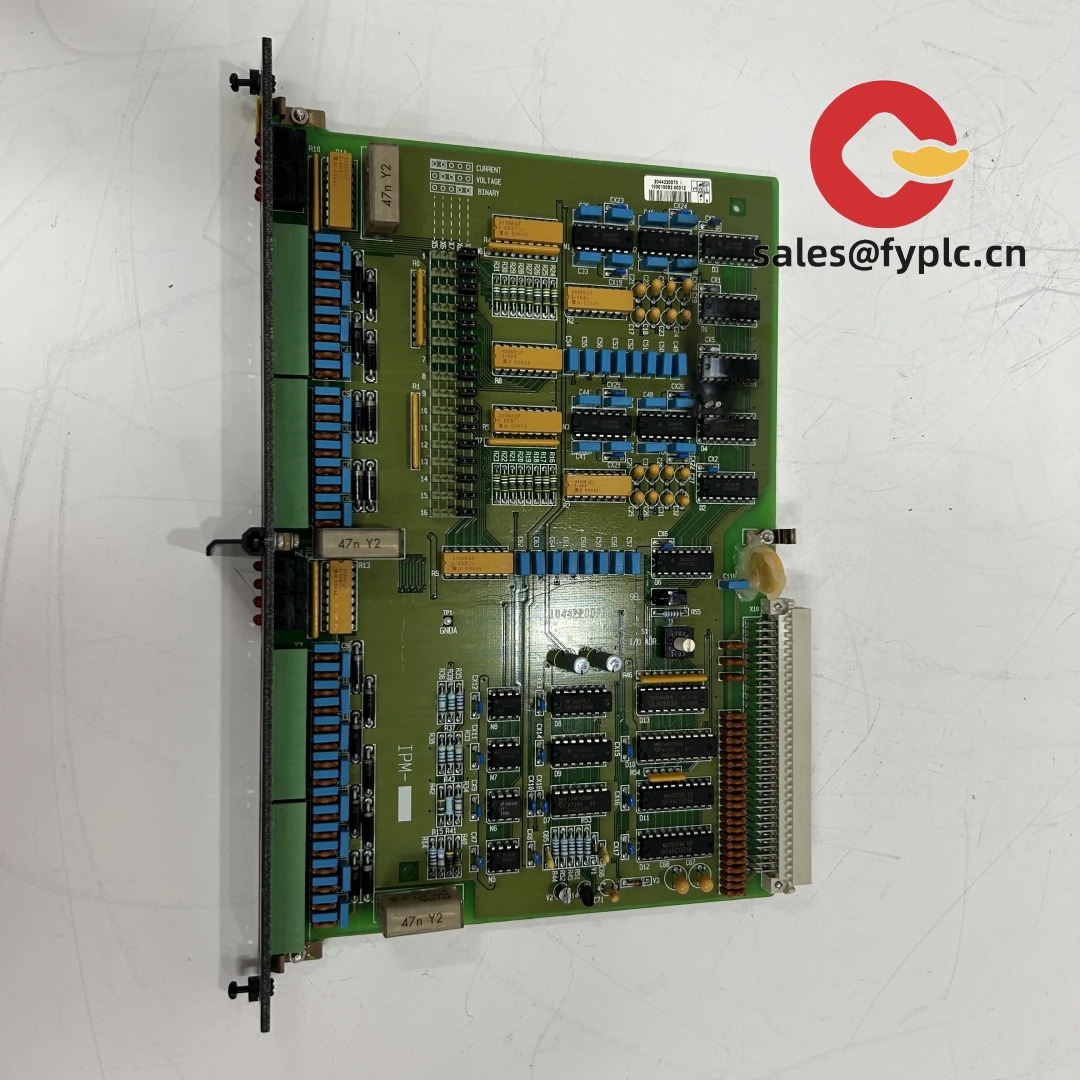

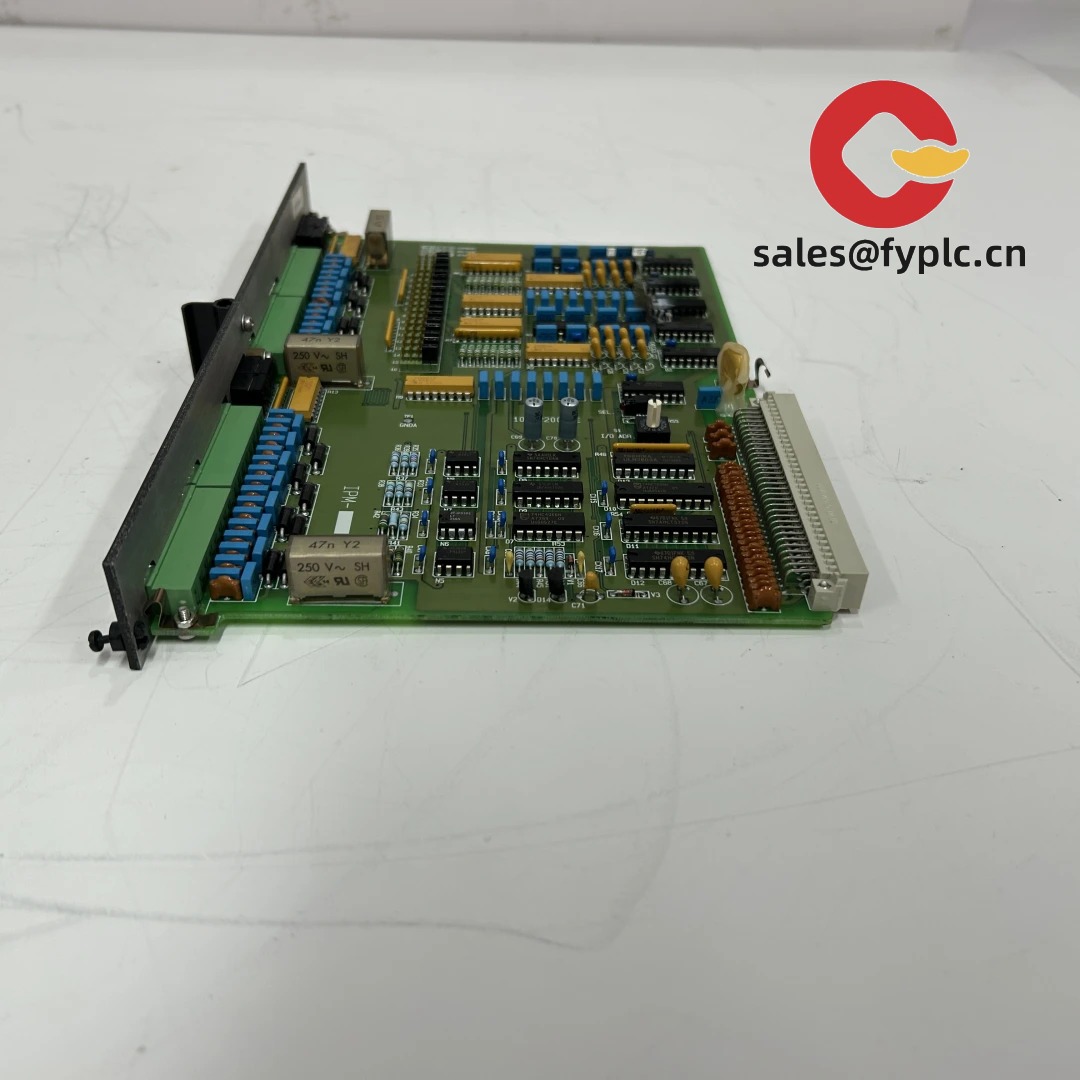

| Signal I/O Types | Digital inputs/outputs for breaker interlocks & commands; optional analog references (e.g., 4–20 mA/0–10 V) depending on configuration |

| Communication Interfaces | Modbus RTU (RS-485) and/or Modbus TCP (Ethernet); CAN-based coordination with DEIF genset controllers in many cases |

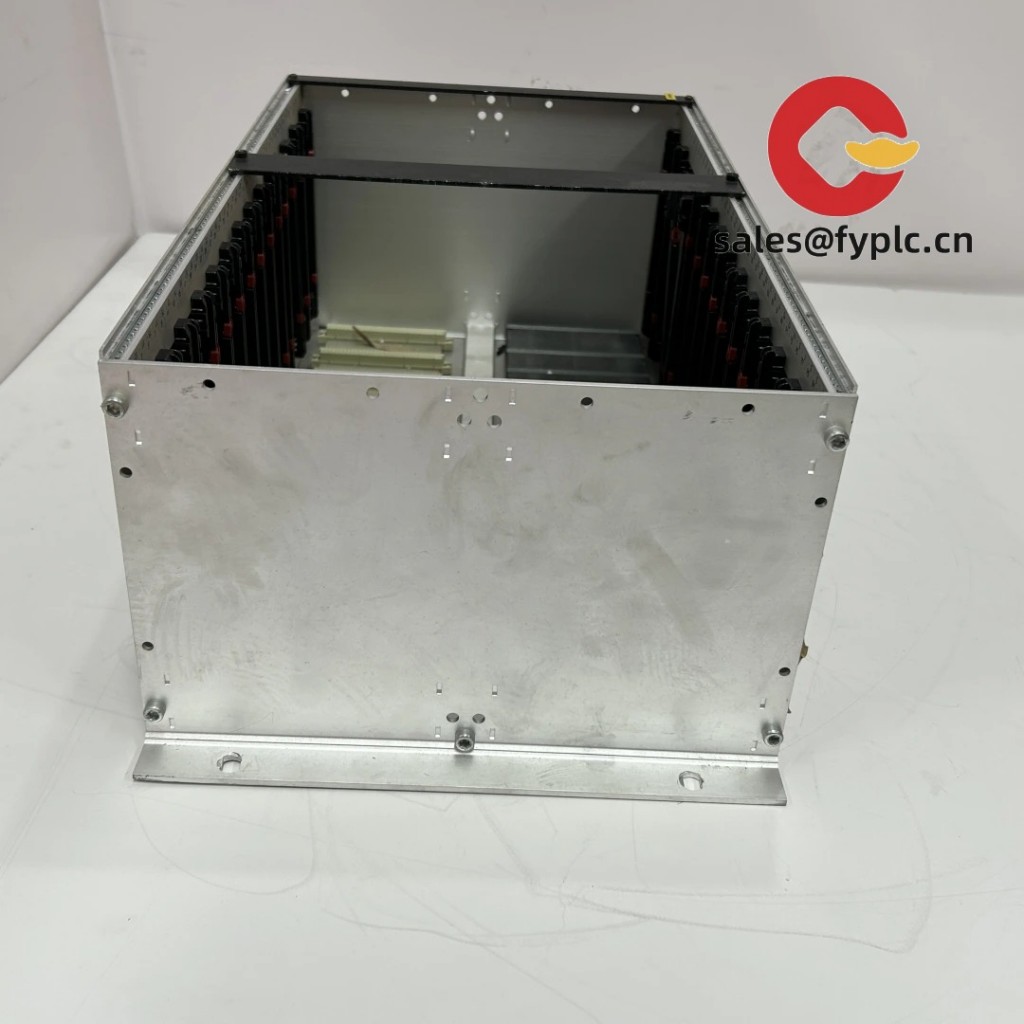

| Installation Method | Control cabinet installation, typically on 35 mm DIN rail or panel backplate; segregate power and signal wiring |

| Dimensions & Weight | Compact controller module; inquire for exact outline drawing when finalizing panel layout |

Application Fields

The IPM-1 is typically used in:

- Industrial plants with multiple gensets and a utility intertie (cement, chemicals, food & beverage)

- Hospitals, data centers, and airports requiring no-break transfer and priority load shedding

- Oil & gas and mining sites where islanded operation and black-start capability matter

- Marine and offshore power systems with multi-bus synchronization and tie-breaker logic

- Microgrids combining diesel, PV, and BESS for peak shaving and import/export control

Advantages & Value

- Reliability – Purpose-built sequencing reduces nuisance trips; breaker checks and interlocks lower operator risk.

- Compatibility – Works seamlessly with DEIF AGC series; Modbus links to existing PLC/SCADA minimize re-engineering.

- Lifecycle savings – Better load sharing and peak shaving typically cut fuel and demand charges; reduces running hours per unit.

- Faster commissioning – Parameter-based setup instead of custom code; clear status and event logs help shorten FAT/SAT.

- Support ecosystem – Firmware tools, application notes, and trained partners; spare parts availability is usually strong.

A maintenance manager at a food plant summed it up neatly: “Once we enabled spinning reserve and automatic shedding, our Monday morning starts stopped tripping the mains breaker. It seems to be doing exactly what we hoped.”

Installation & Maintenance

- Cabinet & environment – Mount in a clean, dry, ventilated control cabinet; allow space for heat dissipation and service access.

- Wiring practices – Use separate routing for power and signal; twisted pair for RS-485; shield and ground as per EMC best practice.

- Breaker interlocks – Verify permissives and feedbacks before live operation; test open/close sequences under supervision.

- Commissioning – Set power import/export limits, load priorities, and spinning reserve; validate with staged load tests.

- Routine maintenance – Back up configuration, review event logs monthly, and update firmware during planned outages; check terminal tightness annually.

Quality & Certifications

- CE compliant; RoHS aligned components

- Manufactured under ISO 9001 quality systems

- UL/cUL conformity available for selected configurations (check specific variant)

- Standard manufacturer warranty: 12 months

Suggested Complementary Components

- DEIF AGC-150 or AGC-4 genset controllers for each generator

- DEIF LS-5 breaker controller for tie/mains breaker automation

- Power meters and protection relays for feeder-level visibility and protection selectivity

If you share your single-line diagram and number of sources/buses, we can pre-validate the configuration, confirm the I/O/communications mix, and align delivery with your FAT schedule.

Reviews

There are no reviews yet.