Description

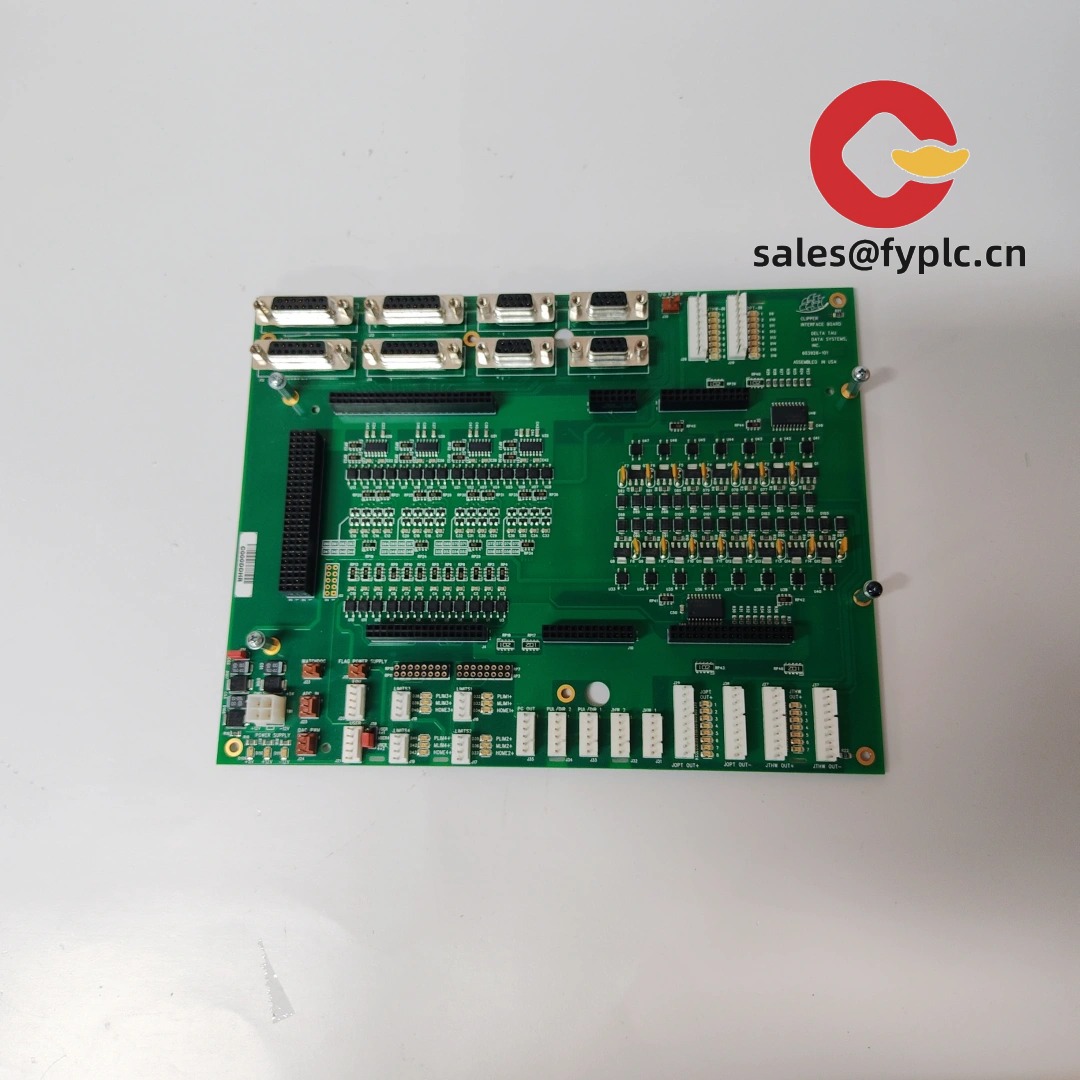

DELTA TAU 603926-101 Clipper Interface Board – Reliable Field I/O Breakout for PMAC Clipper Motion Control

The DELTA TAU (Omron Delta Tau) 603926-101 Clipper Interface Board is designed to simplify wiring and field connections for PMAC Clipper motion controllers. From my experience, this interface board makes panel work cleaner and faster, especially when you need stable connections for encoders, limits, and servo command signals. It seems to be the go-to choice in many retrofit and OEM builds where you want dependable connectivity without overcomplicating the cabinet.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express: FedEx, UPS, DHL

Key Features

- Purpose-built for PMAC Clipper – Directly mates with the Clipper controller, keeping wiring short and clean.

- Field-friendly terminals – Pluggable or screw-type terminal access for encoders, limits, home, and I/O that technicians actually like to work with.

- Supports common motion signals – Works with differential encoder feedback, ±10 V analog servo command or step/direction signals, and 24 VDC digital I/O for machine interlocks.

- Robust in industrial cabinets – Layout typically favors good separation of feedback and power wiring to reduce noise and service callbacks.

- Easy retrofit – Drop-in replacement approach typically shortens panel build time and simplifies maintenance.

- Serviceability – Clear labeling and accessible connectors help reduce commissioning time; you might notice fewer wiring errors on first power-up.

Technical Specifications

| Brand / Model | DELTA TAU / 603926-101 (Clipper Interface Board) |

| HS Code | 853890 (Parts for electrical control apparatus – typical classification) |

| Power Requirements | Powered via connected Clipper controller or cabinet field supply (no separate PSU typically required) |

| Operating Temperature | 0 to 55 °C (industrial control cabinet environment) |

| Signal I/O Types | Differential encoder feedback, ±10 V analog or step/dir command lines, 24 VDC digital I/O for limits/home/E-stop |

| Communication Interfaces | Uses Clipper controller communication (e.g., Ethernet/serial on controller); no separate comms on the board |

| Installation Method | Cabinet mount (DIN-rail or panel plate), with field wiring via terminal blocks |

| Dimensions & Weight | Compact board-level format suitable for standard control enclosures |

Application Fields

This interface board is commonly used anywhere a PMAC Clipper is controlling motion: precision machine tools, packaging and converting lines, pick-and-place and electronics assembly, semiconductor handling, and general-purpose robotics or gantry systems. One thing I appreciate is how it reduces wiring density in retrofits, especially when replacing legacy controllers but keeping existing drives and encoders.

Advantages & Value

- Reliability – Stable signal breakout helps reduce noise-related faults and intermittent encoder alarms.

- Compatibility – Built for PMAC Clipper; typically fits seamlessly into existing Delta Tau control architectures.

- Cost Efficiency – Simplifies cabinet wiring, usually saving technician hours during build and service.

- Supportability – Clear labeling and straightforward routing make troubleshooting faster for maintenance teams.

Customer note: “Our packaging line retrofit went smoother than expected—this Clipper interface board shaved about 30% off panel wiring time and we’ve had zero encoder dropouts so far.”

Installation & Maintenance

- Cabinet standards – Mount in a clean, ventilated industrial enclosure; keep encoder and signal wiring separated from high-voltage conductors.

- Wiring practices – Use shielded twisted pairs for encoders; land shields at a single-point ground. Maintain proper grounding between controller, interface board, and drives.

- Power & I/O – Use regulated 24 VDC for field I/O where required; verify polarity and I/O type (sink/source) before energizing.

- Safety – De-energize the cabinet before changing connections; validate E-stop and limit circuits during commissioning.

- Routine maintenance – Re-torque terminals after thermal cycles, keep the board free of dust, and check encoder diagnostics periodically. Firmware updates apply to the Clipper controller itself rather than this interface board.

Quality & Certifications

- CE and RoHS compliant in most configurations

- Manufactured to industrial-grade standards for continuous operation

- Warranty: 365 days (coverage as stated above)

Need a matching Clipper controller, encoder cables, or compatible Delta Tau accessories? From my experience, bundling these at the same time reduces commissioning delays and ensures connector pinouts match on day one.

Reviews

There are no reviews yet.