Description

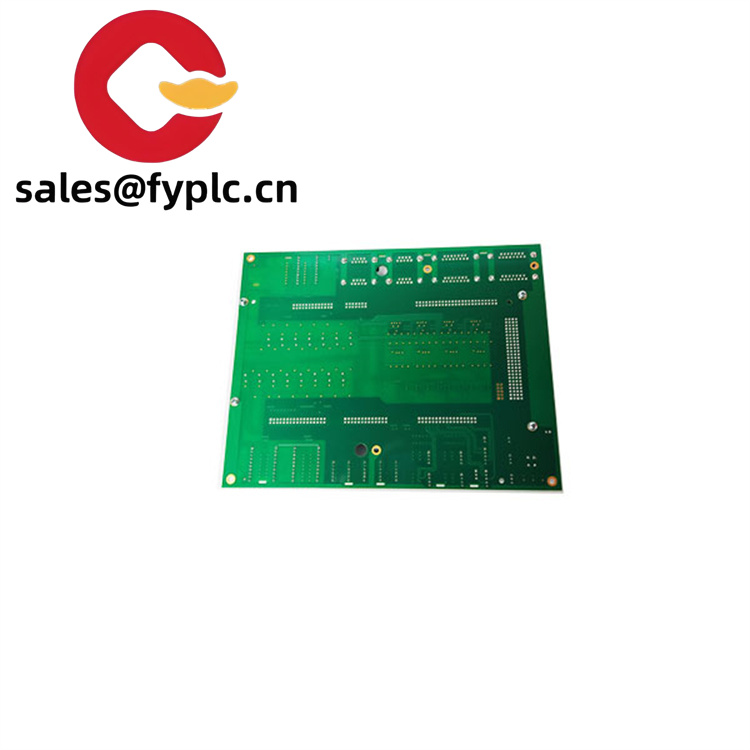

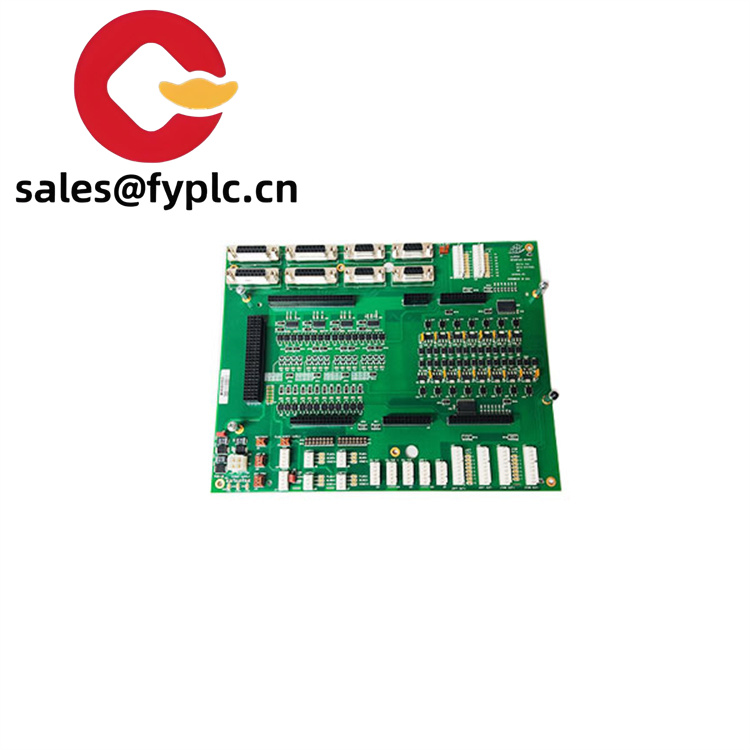

DELTA TAU CLIPPER INTERFACE BOARD 603926-101 Interface Block Controller

The DELTA TAU CLIPPER INTERFACE BOARD 603926-101 serves as a high – performance interface board designed to bridge the gap between different subsystems in an industrial automation setup. Its core function is to facilitate rapid and reliable data transfer, enabling efficient communication between motion controllers, servo drives, sensors, and other critical devices. In industrial environments, it acts as the central nervous system, coordinating the flow of information and ensuring that all components work in harmony.

|

Label

|

Specification

|

|

Model Number

|

603926 – 101

|

|

Brand

|

DELTA TAU

|

|

Type

|

Interface Board

|

|

Input Voltage

|

[Specify accurate input voltage range, e.g., 24 V DC]

|

|

Operating Temp

|

-20°C to 70°C (Operating)

|

|

Communication Method

|

Ethernet, RS – 485, CAN Bus

|

|

Mounting

|

[Describe mounting method, e.g., DIN Rail or Panel Mount]

|

|

Weight

|

Approximately [X] kg

|

|

Certifications

|

CE, UL

|

|

Dimensions

|

[Length] x [Width] x [Height] mm

|

|

Data Transfer Rate

|

Up to [X] Mbps

|

|

Number of I/O Channels

|

[Specify the number, e.g., 32 digital I/O channels]

|

|

Supported Protocols

|

TCP/IP, Modbus RTU, CANopen

|

For more information, please click on the following link:

AB 2711 series 2711-K6C15 touch screen accessories

Rockwell 1762-OW16 Safety Output Module Relay

Triconex 3009 Enhanced Main Processor (UMP) Module

Triconex 3101/Triconex3201 Triple Modular Redundant Main Processor

AB 2711-K6C5 touch screen human-machine interface function module

Allen Bradley 1769-L32C | Processor Analog Input/Output Module

ABB UFC718AE01-HIEE300936R0001 Power Control Equipment Module

Reviews

There are no reviews yet.