Description

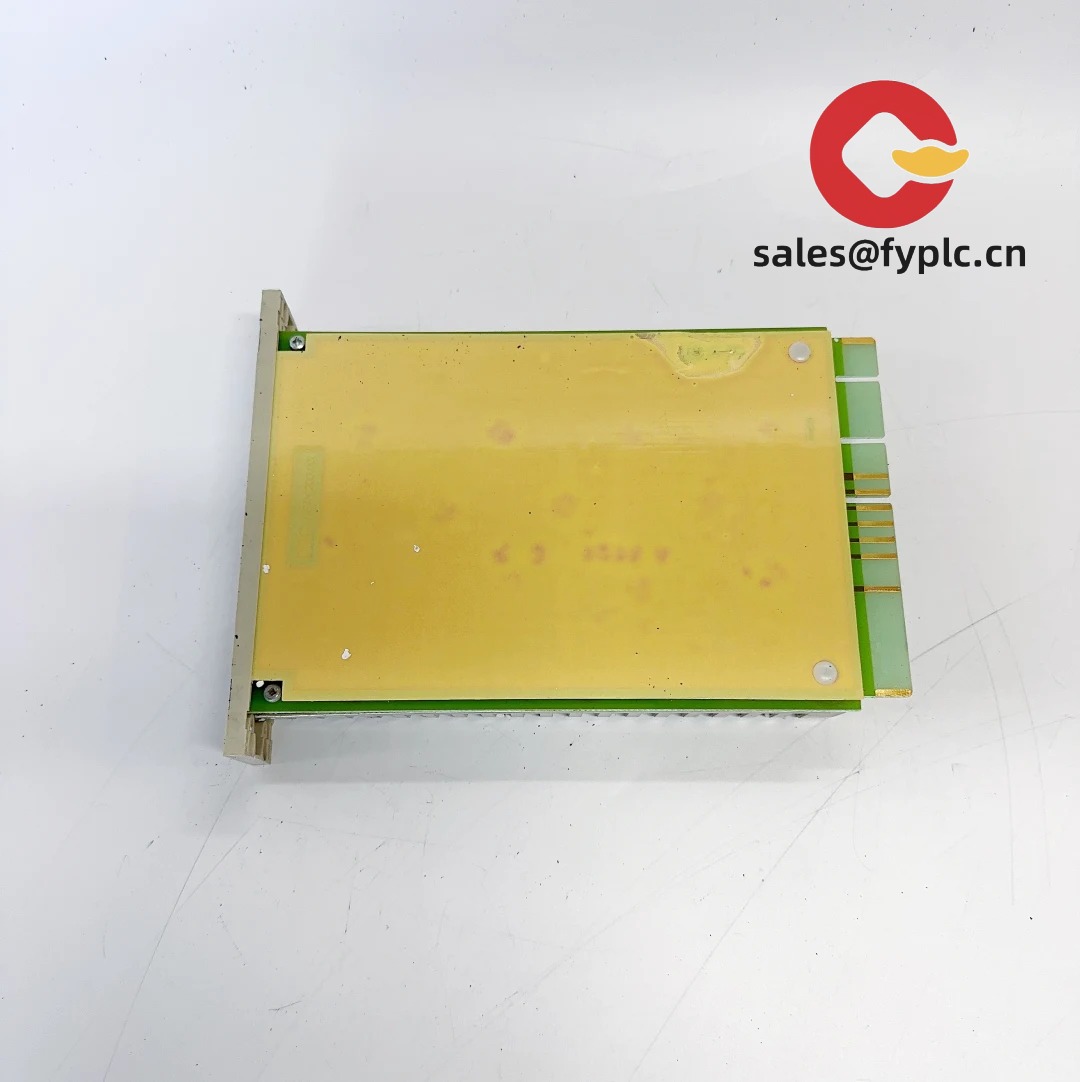

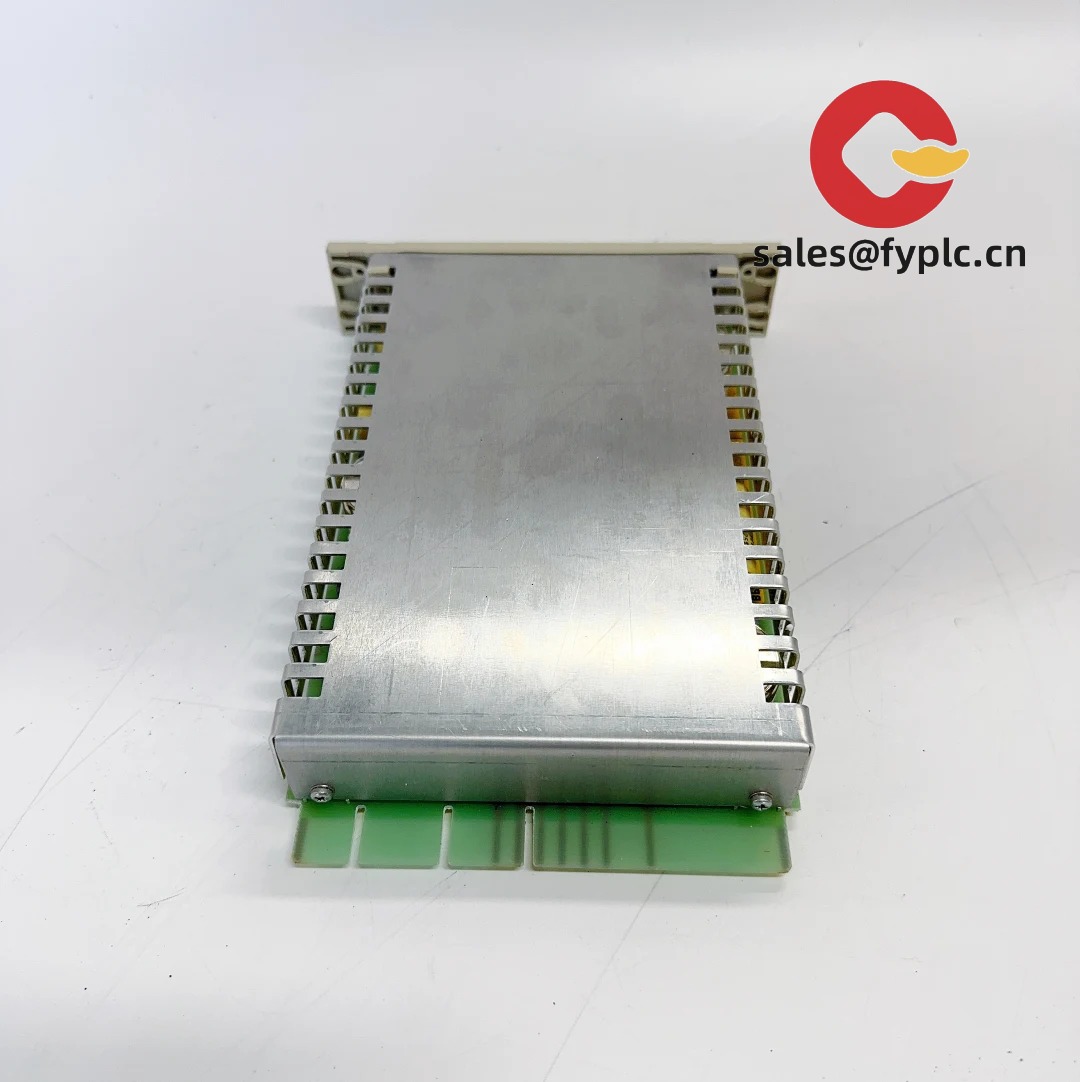

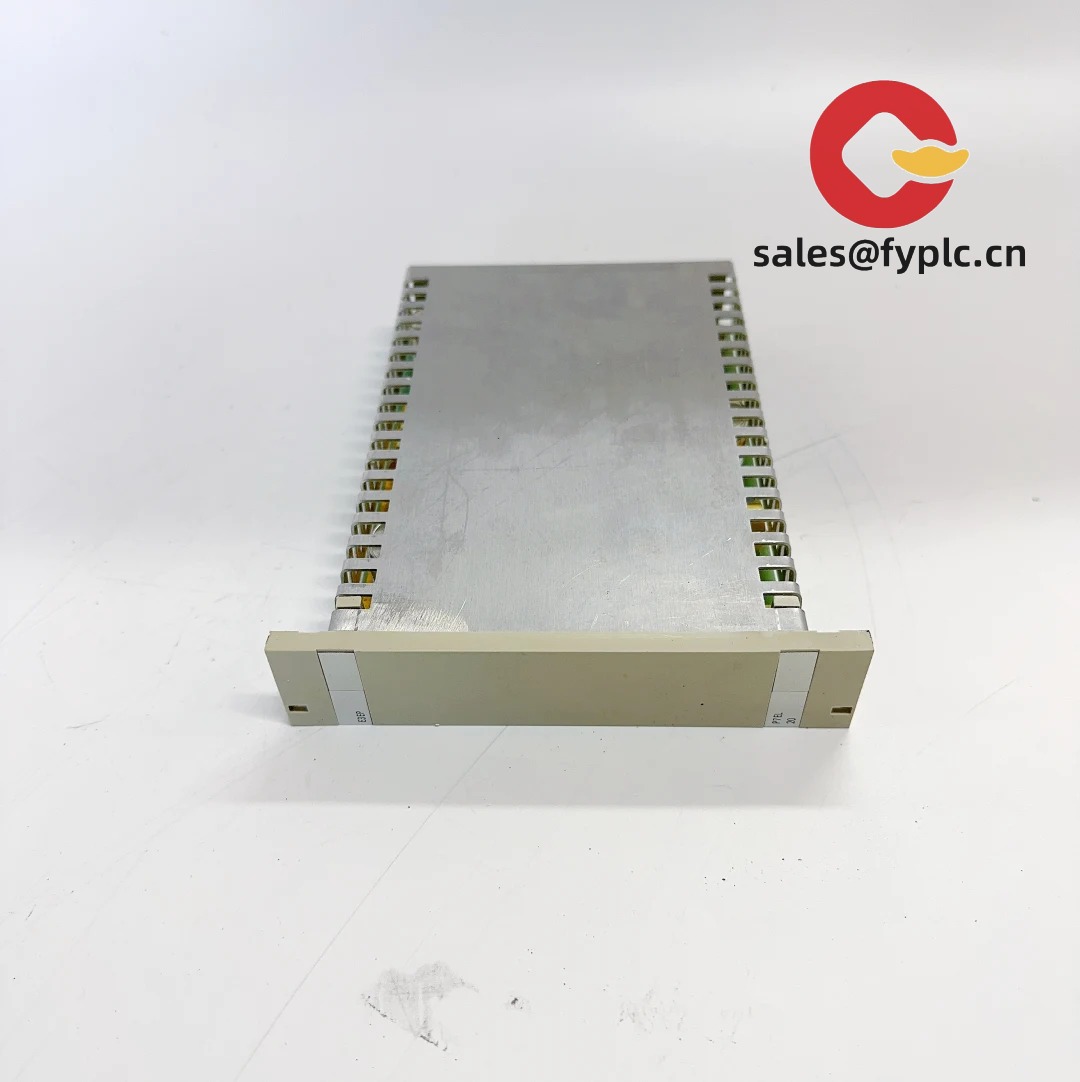

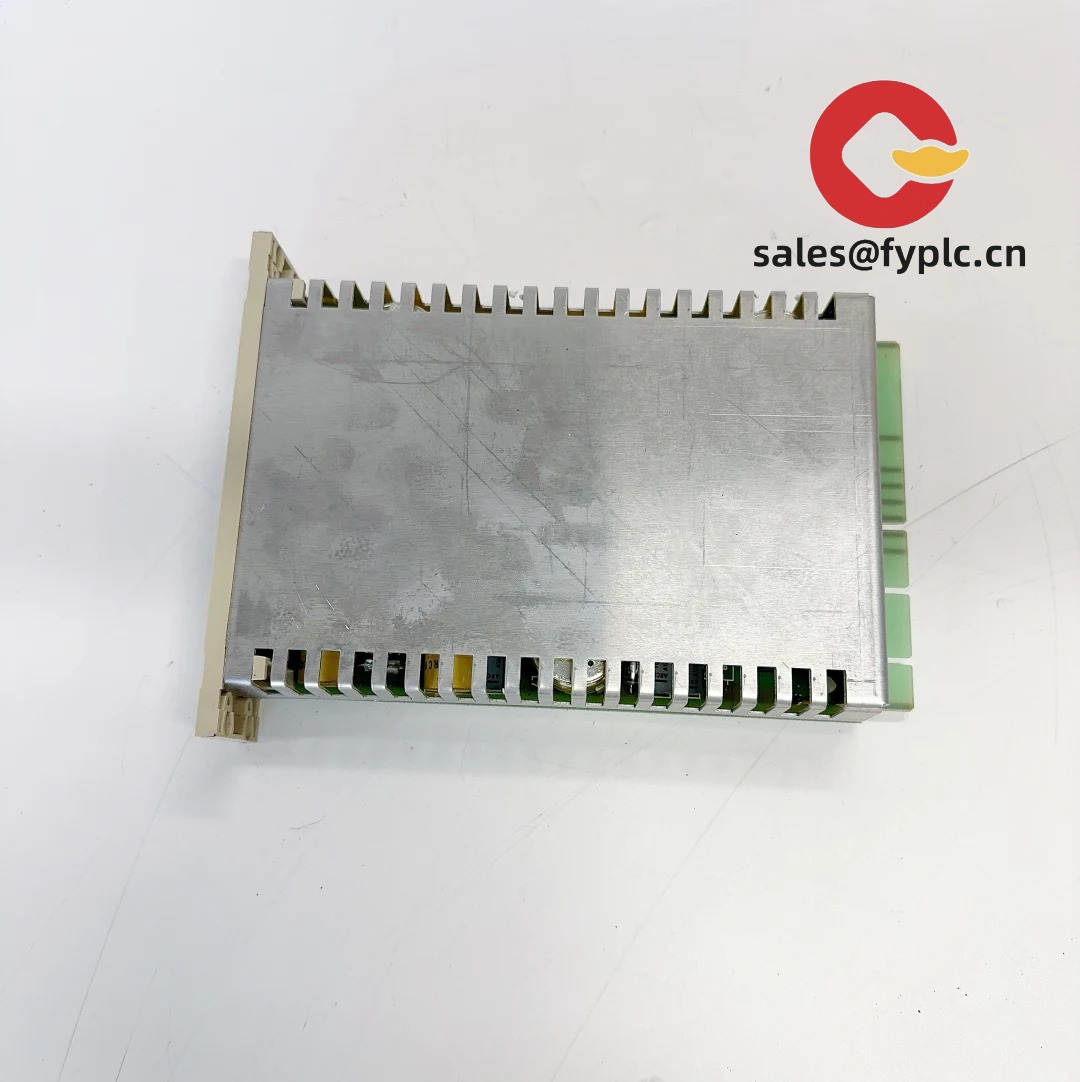

E3EP HENF315276R1 PLC – Compact control for fast, reliable machine automation

The E3EP HENF315276R1 is positioned as a compact Programmable Logic Controller (PLC) for OEM machines and small-to-mid scale process skids. From my experience, it fits best where you need dependable digital I/O, basic analog handling, and straightforward communication without the footprint of a large rack system. You might notice that it leans into practical functions—ladder-friendly logic, simple networking, and tidy DIN-rail installation—so commissioning typically stays quick and predictable.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Compact DIN-rail form factor – Fits crowded control panels and OEM enclosures without redesign.

- Discrete control made simple – Handles typical digital input/output tasks for machinery, conveyors, and packaging stations.

- Analog capability (optional) – In many cases supports voltage/current signals for temperature, pressure, or flow loops.

- Communication you actually use – RS-485/Modbus RTU is commonly available; Ethernet access via selected variants or add-on adapters.

- IEC 61131-3 logic styles – Typically supports ladder diagram and function blocks so technicians can maintain it quickly.

- High-speed counters and timers – Useful for encoders, print marks, and synchronized motion triggers on compact lines.

- Event logging and diagnostics – Basic alarms and data tags help maintenance pinpoint issues faster.

- Clean wiring – Pluggable terminals and clear labeling reduce panel assembly time and wiring errors.

Technical Specifications

| Brand/Model | E3EP HENF315276R1 – Programmable Logic Controller (PLC) |

| HS Code | 8537.10 (Programmable controllers) |

| Power Requirements | 24 VDC nominal (common for compact PLCs; confirm variant before ordering) |

| Dimensions & Weight | Compact DIN-rail module form factor, designed for shallow panels |

| Operating Temperature | Typically 0–55°C (32–131°F); verify per model option |

| Signal I/O Types | Digital inputs/outputs; optional analog (V/mA) on selected variants or expansion |

| Communication Interfaces | RS-485 (Modbus RTU) typical; Ethernet available via expansion or specific models |

| Installation Method | DIN-rail (TS-35) mounting; front-panel access to terminals |

Note: Specifications above reflect common configurations for this PLC family; we will confirm exact build options against your part code prior to shipment.

Application Fields

- Packaging and labeling cells – discrete sequencing, interlocks, and sensor handling.

- HVAC and utilities skids – fan/pump control, PID temperature loops, and alarm handling.

- Material handling – conveyor zoning, jam detection, and simple speed reference control.

- Food & beverage auxiliaries – small mixers, CIP valves, and level monitoring.

- OEM machinery – compact control where a larger rack PLC would be excessive.

A packaging OEM shared that swapping to this model cut their commissioning time by roughly a third because the wiring was straightforward and the Modbus tags matched their HMI template out of the box. That seems to be a common theme with compact PLCs that favor practical features over niche options.

Advantages & Value

- Reliable core control – Solid digital I/O performance for the majority of machine tasks.

- Cost-conscious footprint – Smaller panel space and simpler wiring typically reduce total installed cost.

- Easy integration – Modbus RTU and optional Ethernet simplify PLC–HMI–VFD connectivity.

- Lifecycle support – Long-term availability and straightforward replacement minimize downtime risk.

- Technical backup – Pre-shipment configuration checks and documentation support if you need them.

Installation & Maintenance

- Panel & environment – Install in a ventilated cabinet (IP54 or better for dusty areas). Keep clear of high-heat sources and VFD EMI where possible.

- Wiring – Use ferruled terminations, segregate I/O and power from communication lines, and ground the DIN rail to reduce noise.

- Power – A regulated 24 VDC supply with proper sizing and surge protection is typically recommended.

- Safety – De-energize the panel before service; verify lockout/tagout and use proper fusing or circuit protection.

- Routine checks – Inspect terminals quarterly, clean dust with dry air, back up the program, and document any firmware updates.

- Calibration – For analog loops and temperature/PID tasks, verify scaling and recalibrate sensors during scheduled maintenance.

Supporting Components (commonly paired)

- 24 VDC DIN-rail power supply with overload protection

- RS-485 surge protector/isolator for long Modbus runs

- Ethernet communication adapter (if your HMI/SCADA standardizes on TCP/IP)

- Analog expansion module (V/mA) for additional process signals

- Shielded sensor cables and noise filters when installed near VFDs

Quality & Certifications

- Typically conforms to CE and RoHS for industrial control equipment

- UL/cUL marking may apply depending on specific variant and market

- Warranty: 365 days from our side; factory policies may vary by region

Reviews

There are no reviews yet.