Description

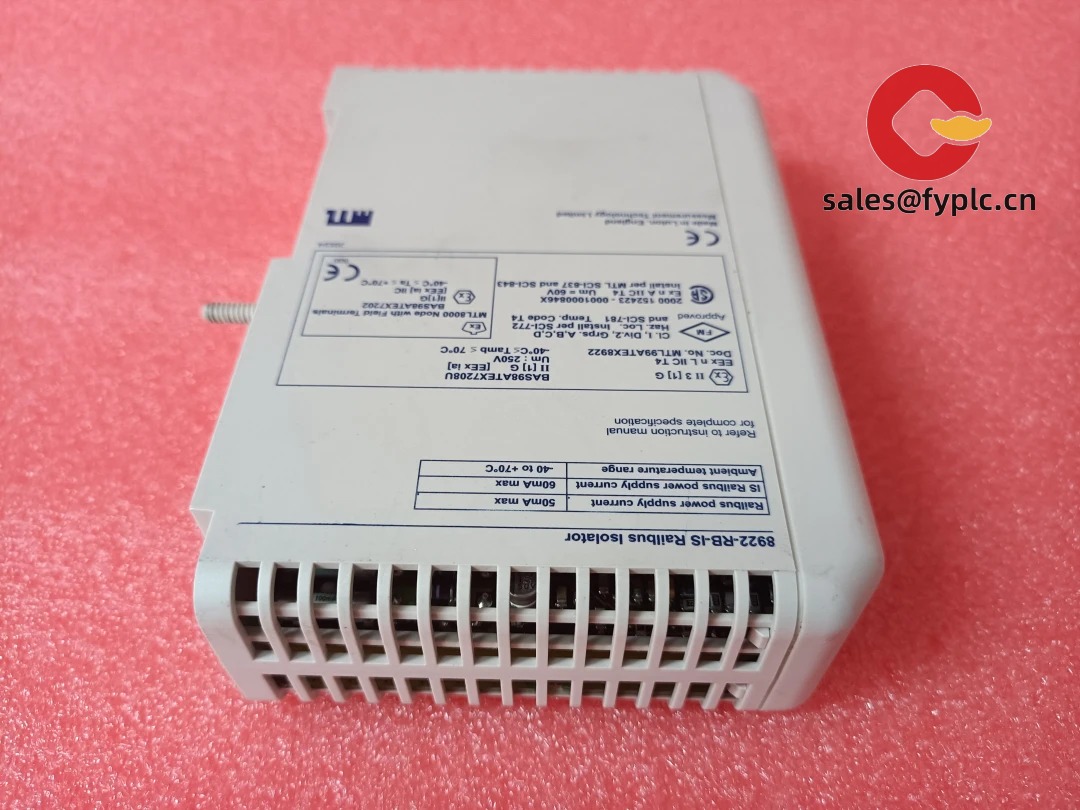

Eaton 8922-RB-IS – Intrinsically Safe Relay Barrier for Hazardous-Area Signals

The Eaton 8922-RB-IS is designed to interface field devices located in hazardous areas with control systems in the safe area. From my experience, it typically serves as an intrinsically safe (IS) relay barrier: you bring in a proximity sensor, contact, or temperature switch from Zone 0/1/2 (or Class I Div 1/2), and the module provides isolated, clean relay output back to your PLC/DCS. You might notice that this approach keeps compliance simple and wiring straightforward—especially on brownfield upgrades where replacing field devices isn’t practical.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Lead time: 1 week when in stock; no more than 1 month at the latest

- Payment terms: 50% advance; balance paid in full prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Intrinsically Safe interface – Allows direct connection of sensors/switches from hazardous areas while limiting energy to safe levels.

- Relay output (SPDT) – Provides a clean, isolated contact back to PLC/DCS/ESD systems; ideal for dry-contact inputs.

- Galvanic isolation – Breaks ground loops and reduces noise pickup between field and control room.

- DIN-rail mounting – Slim-profile module saves cabinet space and simplifies retrofits.

- Status indication – Front LEDs typically show power and channel state for quick diagnostics.

- Hazardous-area compatibility – Suited for Zone 0/1/2 or Class I Div 1/2 signals when installed per entity parameters.

- Low power draw – Runs on common 24 VDC control power; easy to integrate with existing PSU capacity.

Technical Specifications

The values below reflect the typical configuration for this model class. If you’re matching a specific loop (sensor type, gas group, cable L/C), share the details and we’ll verify entity parameters before shipment.

| Brand / Model | Eaton 8922-RB-IS |

| HS Code | 8543.70 (Electrical apparatus with individual functions, not specified elsewhere) |

| Power Requirements | 24 VDC nominal (20–30 VDC), ≤1.5 W consumption |

| Signal Input (Hazardous Area) | NAMUR proximity or dry contact; entity-limited for Zone 0/1/2 (or Class I Div 1/2), blue terminals |

| Signal Output (Safe Area) | Relay SPDT, up to 5 A @ 250 VAC / 30 VDC (resistive); status LED indication |

| Isolation | Galvanic isolation between input, output, and supply (typ. 2.5 kVrms) |

| Operating Temperature | -20 to +60 °C (typical industrial range) |

| Dimensions & Weight | Approx. 12.5 mm (W) × 99 mm (H) × 114 mm (D); ~120 g module weight |

| Communication Interfaces | Not applicable; front LEDs for diagnostics |

| Installation Method | 35 mm DIN rail (EN 60715); screw/plug-in terminals 0.2–2.5 mm² |

Application Fields

Typical use cases include:

- Oil & gas skids (level alarms, pressure switches, proximity sensors in Zone 1)

- Chemical and petrochemical process lines where IS loops simplify compliance

- Pharmaceutical reactors and batching systems requiring low-energy interfaces

- Paint shops and solvent storage (Class I Div 1/2) with simple contact signals

- Water/wastewater lift stations bringing float switch signals back to SCADA

- Grain handling and milling where IS proximity detection reduces ignition risk

Advantages & Value

- Compliance made practical – Intrinsic safety typically avoids heavy explosion-proof enclosures for the device itself, saving installation time and cost.

- Compatibility – Works with common NAMUR proximity sensors and mechanical contacts; easy to land on standard PLC digital inputs via relay.

- Noise immunity – Galvanic isolation helps stabilize chattering or nuisance trips on long cable runs.

- Cabinet efficiency – Narrow width means more channels per row; helpful in MCC and marshalling cabinets.

- Procurement assurance – Stable lead times and a 365‑day warranty reduce project risk, especially for shutdowns or tie-ins.

Installation & Maintenance

- Cabinet & mounting – Install on 35 mm DIN rail in a ventilated enclosure (IP54 or better recommended); allow modest airflow and avoid heat sources.

- Grounding – Bond the IS barrier earth per the manual; a solid PE connection is critical for energy-limiting performance.

- Wiring – Use blue wiring/marking for IS circuits; verify cable capacitance/inductance stays within entity limits for your gas group.

- Segregation – Maintain separation between IS and non‑IS wiring; route away from VFD cables to minimize interference.

- Commissioning – Perform loop checks at low energy, verify LED status, and document entity parameter compliance for each loop.

- Routine care – No regular calibration is typically needed; keep terminals tight, dust the module during PMs, and re‑verify bonding continuity annually.

Quality & Certifications

- ATEX / IECEx approvals for intrinsic safety (model‑dependent marking)

- UL / cUL listings for Class I, Division 2 installations (typical for this series)

- CE and RoHS compliance

- Manufacturer’s warranty: 12 months from shipment

Optional Accessories & Supporting Components

- Eaton PSG Series 24 VDC power supplies – Reliable DIN‑rail PSUs sized for multi‑channel IS barriers.

- DIN rail end stops – Prevents module movement in high‑vibration panels.

- Grounding busbar kits – Clean bonding point for IS earth and shielding.

- Field junction boxes (hazardous‑area rated) – Eaton Crouse‑Hinds enclosures to transition IS field wiring safely.

If you share your loop details (sensor type, distance, gas group, and cabinet power), we can validate the 8922-RB-IS configuration and ship with the right accessories so installation goes smoothly the first time.

Reviews

There are no reviews yet.