Description

EATON MP3010 Motor Protection Relay – Reliable Protection and Diagnostics for Low-Voltage Motors

The EATON MP3010 is a dedicated motor protection relay designed to safeguard three-phase motors against the common issues that typically cause downtime—overload, phase loss, unbalance, locked-rotor, and ground faults (with suitable CTs). From my experience, plants choose the MP3010 when they want dependable trip logic, straightforward wiring, and clear status indications without overcomplicating the panel. It slots in nicely for pumps, fans, conveyors, mixers—anywhere you need consistent protection and meaningful alarms that maintenance can act on quickly.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Comprehensive motor protection – Overload (thermal model), phase loss, phase unbalance, jam/stall, and ground fault (with appropriate CT), helping prevent nuisance trips and equipment damage.

- CT-based current monitoring – Works with 1 A or 5 A secondary CTs, which makes it easy to adapt to different motor sizes without changing the relay.

- Clear alarms and trip records – You might notice faster troubleshooting because the relay stores cause-of-trip details and status indicators that maintenance can read quickly.

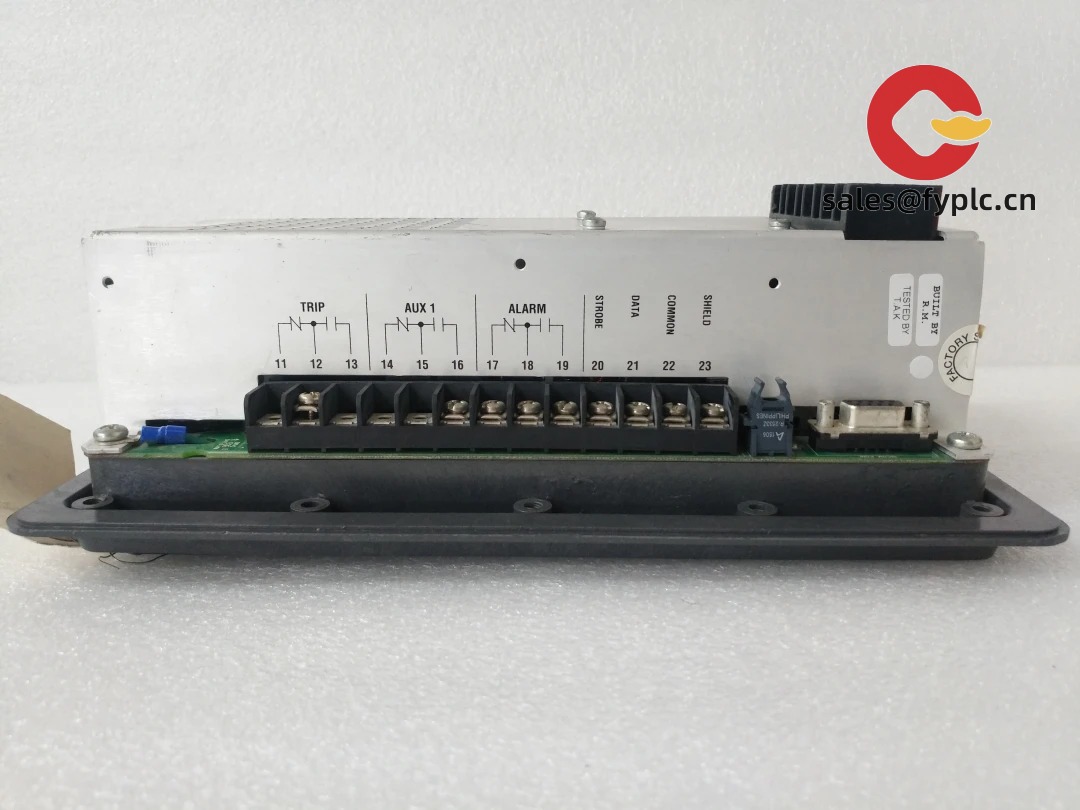

- Programmable I/O – Typically includes digital inputs and multiple Form C relay outputs, so you can tie trips and alarms to PLCs, MCC starters, or remote annunciation.

- Communication-friendly – RS‑485 Modbus RTU is common, with expandability to fieldbus (if equipped) for plants standardizing on network diagnostics.

- Flexible installation – Panel/door-mounted format with terminal blocks suits MCC buckets or wall-mount control panels; wiring is straightforward.

- Setpoints that match the process – From start-time supervision to overload class and unbalance thresholds, parameters can be dialed in to match motor duty.

Technical Specifications

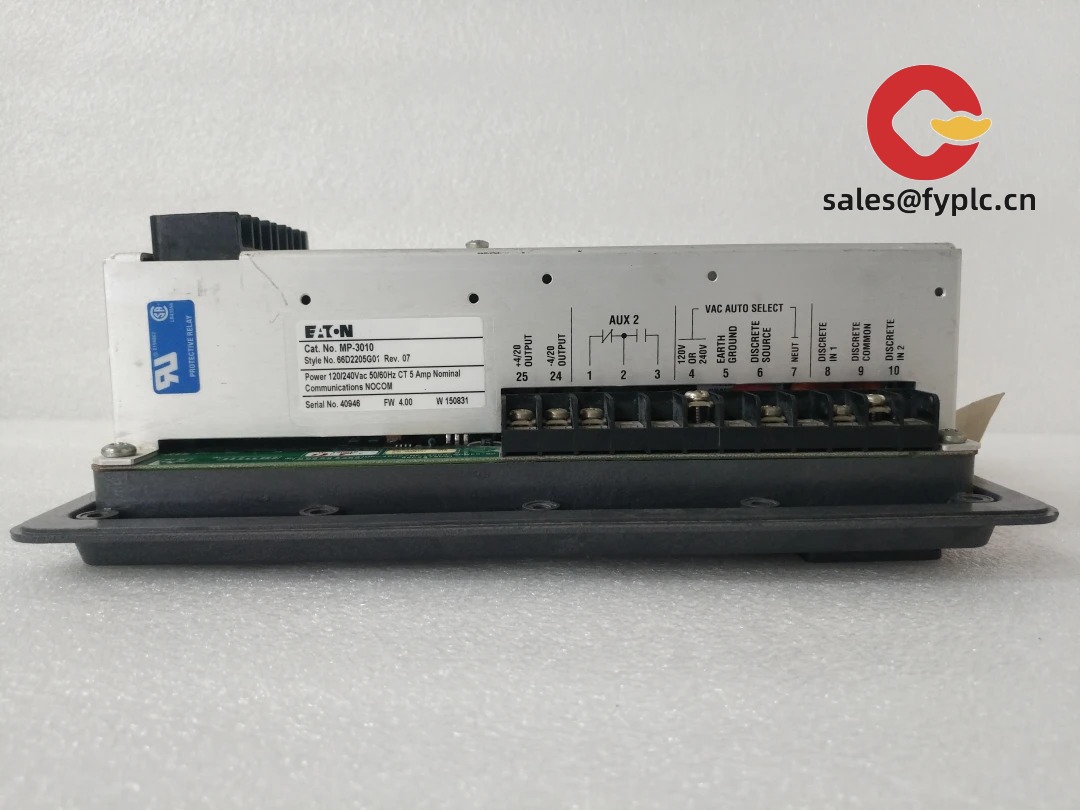

| Brand / Model | EATON MP3010 Motor Protection Relay |

| HS Code | 8536.49 (Relays for electrical control/protection, other) |

| Power Requirements | Auxiliary 24 VDC nominal (typically 18–30 VDC). Some MP3000-series variants support 100–240 VAC auxiliary—verify the nameplate for your MP3010 unit. |

| Dimensions & Weight | Panel-format relay; front ~96 × 96 mm, depth ~110 mm; approx. 0.8–1.0 kg (typical for this series). |

| Operating Temperature | -20 to +60 °C (typical application range) |

| Signal Input/Output Types | 3-phase current via CTs (1 A/5 A); digital inputs; programmable Form C relay outputs for trip/alarm; 4–20 mA analog output if equipped; optional RTD inputs on higher variants. |

| Communication Interfaces | RS‑485 Modbus RTU (commonly used). Optional fieldbus gateways (e.g., Profibus DP, DeviceNet) may be available depending on configuration. |

| Installation Method | Panel/door mounting with screw terminals. Wire CT secondaries (1 A or 5 A) and auxiliary supply as per the terminal layout. Use in an enclosed cabinet (IP54 or better recommended). |

| Protection Functions | Thermal overload, phase loss, phase unbalance, jam/stall protection, ground-fault (with appropriate sensing configuration). |

Application Fields

The MP3010 fits low-voltage motor control centers and standalone panels across water/wastewater (pumps, blowers), HVAC (chillers, cooling towers), mining and aggregates (conveyors, crushers), chemical and pharma (agitators, mixers), and general manufacturing (fans, extruders, compressors). One thing I appreciate is how predictable it is in pump stations: you can tighten the jam/stall window to protect against dry-run or blocked impellers without tripping on normal start-up inrush.

Advantages & Value

- Reliable protection – Stable algorithms reduce nuisance trips while still reacting fast to genuine faults.

- Easy retrofit – Works with standard 1 A/5 A CTs and typical MCC wiring, so upgrade projects move quickly.

- Compatibility – Integrates with PLCs and SCADA over Modbus RTU; in many cases, no gateway is needed.

- Cost control – Fewer motor failures and shorter diagnostics time generally translate to lower maintenance spend.

- Supportable long-term – Parameters are transparent; technicians can adjust setpoints without proprietary software in most cases.

Installation & Maintenance

- Panel environment – Mount in a clean, ventilated enclosure; maintain ambient within the specified temperature range.

- Wiring practices – Keep CT secondary leads twisted and short; land shielded comms cables for RS‑485. Always short CT secondaries before servicing.

- Protection coordination – Coordinate trip curves with upstream breakers/fuses and downstream contactors or soft starters.

- Routine checks – Verify tightening torque on terminals every maintenance cycle; review trip logs monthly for early warnings.

- Calibration & firmware – Confirm CT ratios and overload class after motor changes; update firmware if the unit supports it and your site policy allows.

- Safety – De-energize auxiliary supply and follow lockout/tagout procedures before making adjustments or wiring changes.

Quality & Certifications

The MP3010 series is typically supplied with CE marking and UL/cUL recognition for industrial control equipment. RoHS compliance is standard for most recent builds. Manufacturer’s warranty is 12 months (365 days) under normal use. If you need a formal certificate pack (Declaration of Conformity, UL file reference), we can include it with the shipment or provide it in advance for approvals.

From the field

A food & beverage client swapped legacy thermal overloads on their conveyor line for MP3010 units and reported fewer unplanned stops. What stood out to them was the unbalance alarm: it alerted maintenance to a loose lug before it turned into a motor failure. That seems to be where the MP3010 pays for itself—in catching issues early without constantly tripping the line.

Reviews

There are no reviews yet.