Description

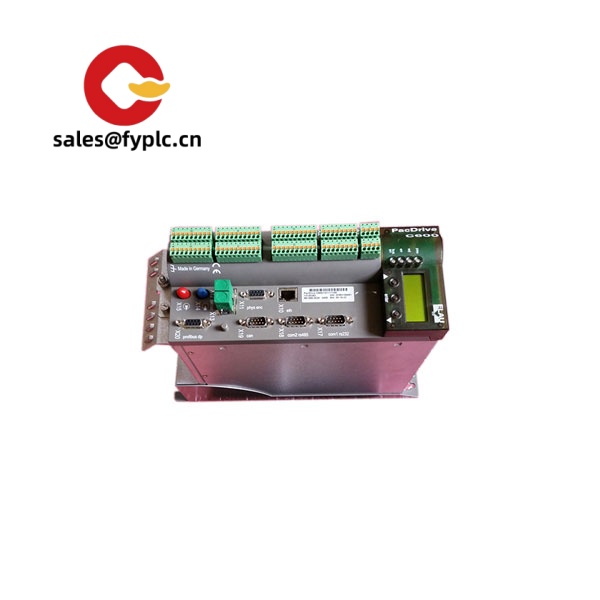

ELAU PacDrive C600/10/11/00 Motion/Logic Controller – High‑speed synchronized servo control for packaging lines

The ELAU PacDrive C600/10/11/00 (often written as C6001011100) is a proven motion/logic controller designed for machine builders who need tightly synchronized multi‑axis motion. It’s widely used on cartoners, flow‑wrappers, form‑fill‑seal machines, and delta robot cells where deterministic motion and fast product changeovers are essential. From my experience, the C600 series pairs especially well with SERCOS‑based servo drives in applications that run 24/7 and can’t tolerate jitter or drift.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days from delivery

- Lead time: typically 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

- Each unit is function‑checked before shipment; test documents can be provided on request

Key Features

- Integrated motion + logic – Coordinates multiple servo axes with deterministic task cycles, typically down to the millisecond range for precise product handling.

- SERCOS drive bus – Fiber‑optic SERCOS interface for noise‑immune, real‑time communication with servo amplifiers.

- 24 VDC control power – Simplifies cabinet design and service; common in European and North American packaging equipment.

- IEC 61131‑3 programming – Structured Text, Ladder, and Function Blocks support for clear, maintainable application code.

- Packaging‑grade robustness – Built for continuous operation; in many cases these controllers run years with minimal intervention.

- Flexible I/O architecture – Typically no onboard I/O; add modular remote I/O over the motion network to place modules where they’re needed.

- Service & diagnostics – Ethernet for engineering/HMI, plus a serial service port for low‑level troubleshooting when required.

Technical Specifications

| Brand / Model | ELAU PacDrive C600/10/11/00 (C6001011100) |

|---|---|

| HS Code | 8537.10 (Programmable controllers; control panels for ≤1000 V) |

| Power Requirements | 24 VDC control supply (typical operating range 18–30 VDC) |

| Operating Temperature | Typically +5 °C to +45 °C in a ventilated control cabinet |

| Signal I/O Types | Remote I/O via motion/fieldbus modules; no large onboard I/O block (select digital/analog modules as needed) |

| Communication Interfaces | SERCOS (fiber‑optic) for drives; Ethernet 10/100Base‑T for HMI/engineering; RS‑232 service port |

| Installation Method | Control cabinet installation; book‑size footprint, typically DIN‑rail or panel mounting with brackets |

Application Fields

You’ll see the PacDrive C600 in high‑speed packaging, food and beverage, and pharma. It seems to be a solid fit for:

- Horizontal/vertical form‑fill‑seal machines with cam‑like electronic motion profiles

- Cartoners, case packers, palletizers with coordinated conveyors and pick heads

- Delta and SCARA pick‑and‑place cells synchronized to moving webs or belts

- Labelers, flow‑wrappers, and dose/dispense stations needing precise timing

One thing I appreciate is how quickly teams can change formats. Recipe‑driven motion lets operators switch SKUs without mechanical re‑cams, which saves hours per week on busy lines.

Advantages & Value

- Reliability – Built for continuous industrial service; in most cases units run for years with only routine cleaning.

- Compatibility – Works with SERCOS‑based servo drives and modular I/O commonly found on ELAU/Schneider Electric PacDrive machines.

- Lifecycle cost – Keeping the same controller family reduces re‑engineering during retrofits, minimizing line downtime and validation effort.

- Supportability – Ethernet access simplifies backups, recipe management, and remote diagnostics.

“We swapped in a C600 controller on a flow‑wrapper line and were producing in under a day. Servo phasing matched right up, no surprises.” – Packaging OEM service manager

Installation & Maintenance

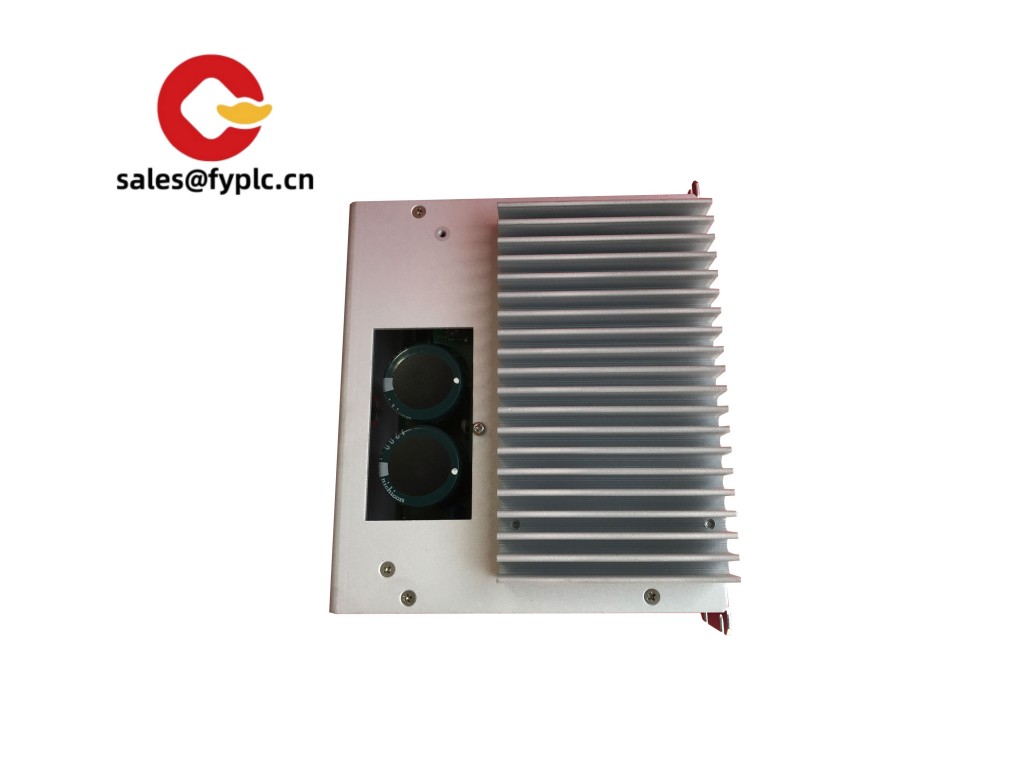

- Cabinet environment – Mount in a dry, ventilated enclosure; maintain ambient temperature within the stated range and provide airflow around the heat‑dissipating surfaces.

- Power & grounding – Use a stabilized 24 VDC supply and a low‑impedance protective earth. Keep power and signal wiring separated to reduce noise.

- Fiber handling – SERCOS uses fiber‑optic cables; avoid tight bend radii and keep ferrules clean to prevent intermittent drive comms.

- Wiring – Torque connectors per spec. Label SERCOS ring connections and Ethernet service ports for faster troubleshooting.

- Routine service – Back up application/recipes after changes, check connectors quarterly, remove dust buildup, and, where applicable, apply firmware updates during planned downtime.

- ESD & safety – Use ESD precautions when handling boards and disconnect power before plugging/unplugging modules.

Quality & Certifications

- Typically CE‑marked for industrial machinery use

- UL/cUL recognition may depend on the exact revision; confirm per nameplate if your site requires UL

- Manufacturer quality systems commonly aligned with ISO 9001

- RoHS status varies by production year; we can verify by serial/lot before shipment

- Warranty: 365 days

Recommended Supporting Components

To speed up commissioning and keep spares standardized, many teams pair the C600/10/11/00 with:

- SERCOS fiber‑optic patch cables and repeaters rated for industrial cabinets

- Remote I/O modules compatible with the PacDrive/SERCOS architecture (digital and analog variants)

- 24 VDC industrial power supplies with redundancy or buffer modules for ride‑through

- Industrial Ethernet switch (managed, 10/100) for HMI/engineering access and segmented service networks

If you’re replacing an existing ELAU PacDrive controller, you might notice that keeping the same SERCOS topology and cable lengths usually shortens validation. Send a photo of your current cabinet layout and we’ll double‑check connector styles, firmware strategy, and recommended spares before you order.

Reviews

There are no reviews yet.