Description

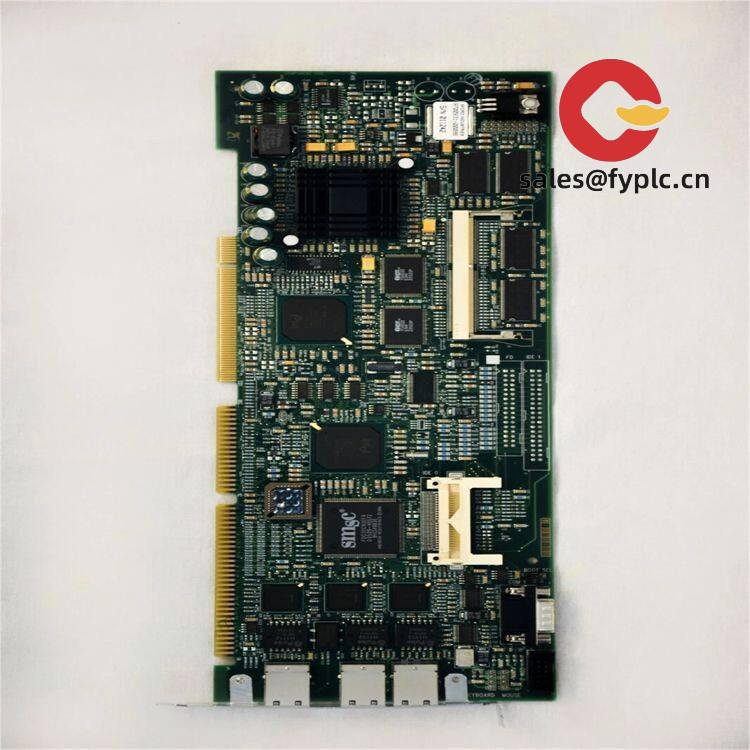

Emerson 1C31194G04 Valve Positioner Module – Precise Valve Control and Feedback for Ovation DCS

The Emerson 1C31194G04 is a valve positioner interface module designed for the Ovation distributed control system. From my experience, plants use it to drive control-valve positioners with a clean 4–20 mA command and bring back position feedback for tighter loops and faster diagnostics. You might notice that it feels purpose-built for power, water, and process units where smart positioners (like Fisher FIELDVUE) are common and uptime really matters.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Valve command and feedback in one module: Typically provides 4–20 mA drive to the positioner and returns a 4–20 mA position signal for closed-loop accuracy.

- Optimized for Ovation DCS: Backplane integration makes configuration, alarming, and diagnostics straightforward through familiar Ovation tools.

- Channel isolation and robust EMC design: Designed to reduce noise coupling from solenoids and actuators, which, in many cases, stabilizes loops during load changes.

- Status LEDs and built-in diagnostics: Clear channel/status indication so technicians can see at a glance whether the loop is healthy.

- Redundancy-friendly architecture: Works within typical Ovation redundant I/O carrier schemes to maintain availability during maintenance or faults.

- HART transparency (site-dependent): Many installations use it alongside AMS to access device parameters without lifting wires, which saves time during turnarounds.

- Hot-swap in most cabinets: In many cases, you can replace the module with the controller in run mode, minimizing process impact.

Technical Specifications

| Brand / Model | Emerson 1C31194G04 |

| Product Type | Valve Positioner Module for Ovation DCS |

| HS Code | 853890 (Parts of electrical control apparatus) |

| Power Requirements | Backplane-powered via Ovation I/O carrier; no external supply required for module logic. Field current loops may require external 24 VDC depending on site design. |

| Signal I/O Types | 4–20 mA analog output to valve positioner; 4–20 mA analog input for position feedback; channel status indicators. HART pass-through commonly supported in Ovation environments. |

| Communication Interfaces | Ovation backplane I/O bus to controller; field wiring via front terminal block/terminal assembly. |

| Operating Temperature | 0 to +55°C typical for control-room rated cabinets |

| Installation Method | Single-slot plug-in module for Ovation I/O carrier; mounted in a 19-inch control cabinet with appropriate grounding and shielding. |

| Form Factor | Compact, lightweight module; standard Ovation I/O form factor |

Application Fields

Typically used wherever precise valve actuation and dependable feedback are critical:

- Power generation (boiler, turbine, balance-of-plant loops)

- Oil & gas and petrochemical (flow/pressure control, compressor anti-surge auxiliaries)

- Water & wastewater (filter valves, clarifiers, chemical dosing)

- Pulp & paper, mining, and general process industries

Advantages & Value

- Seamless compatibility: Drop-in fit for Ovation—no adapters, no surprises during commissioning.

- Reliability under real plant conditions: Seems to be very forgiving with electrical noise from actuators and solenoids, which reduces nuisance trips.

- Lower lifecycle cost: Proven module family with readily available spares; minimizes training overhead for your maintenance team.

- Diagnostics that save time: Quick loop checks and obvious status indicators cut mean-time-to-repair during outages.

Feedback from a maintenance supervisor: “We swapped in the 1C31194G04 during a short window—no rewire—and immediately saw steadier valve response on our deaerator level. That alone paid for the effort.”

Installation & Maintenance

- Cabinet and mounting: Install in a clean, ventilated 19-inch control cabinet. Keep ambient within control-room limits and avoid direct heat sources.

- Wiring practices: Use shielded twisted pairs for 4–20 mA loops; land shields at one end only to prevent ground loops. Separate signal from high-voltage and inductive loads.

- Grounding: Bond cabinet and carrier ground properly; maintain low-impedance earth to improve EMC immunity.

- Loop power: Verify whether loops are powered by the module or an external 24 VDC supply. Check polarity on positioner terminals before energizing.

- Commissioning: Perform loop checks, simulate 0/50/100% commands, and confirm feedback tracks within expected linearity. Record as-found/as-left values.

- Maintenance: Periodically inspect terminal tightness, clean dust with dry air, and review diagnostics. Firmware/config updates should follow your Ovation MOC procedures.

- Spare strategy: Keep at least one spare module per cabinet section; the module is typically hot-swappable in redundant setups.

Quality & Certifications

- Quality system: Manufactured under an ISO 9001 quality framework (typical for Emerson process products).

- Compliance: CE marking for EMC and safety; RoHS conformity; UL/CSA recognition is common across the Ovation I/O family.

- Warranty: Supplier warranty is 365 days; manufacturer’s regional warranty terms may vary by project.

Related and Supporting Components

- Ovation I/O carrier and terminal assemblies for the 1C31194G04

- Fisher FIELDVUE DVC series positioners for smart diagnostics and HART access

- Redundant Ovation controller modules and cabinet power supplies for high availability

- Shielded terminal blocks and cable management accessories for clean routing

Specification details can vary slightly by hardware revision. If you share your current carrier and firmware levels, I can match the 1C31194G04 to your exact Ovation configuration and confirm loop powering on your valve positioners.

Reviews

There are no reviews yet.