Description

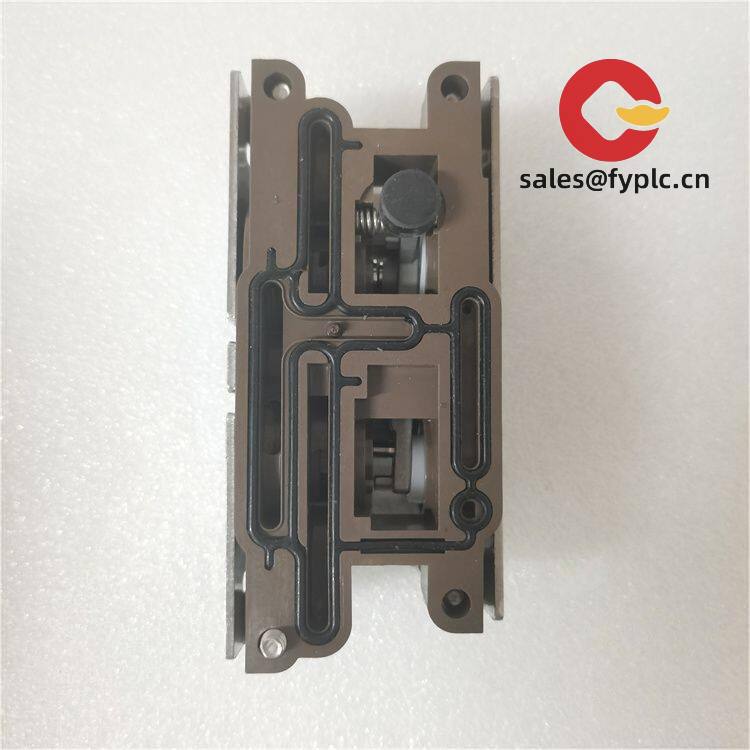

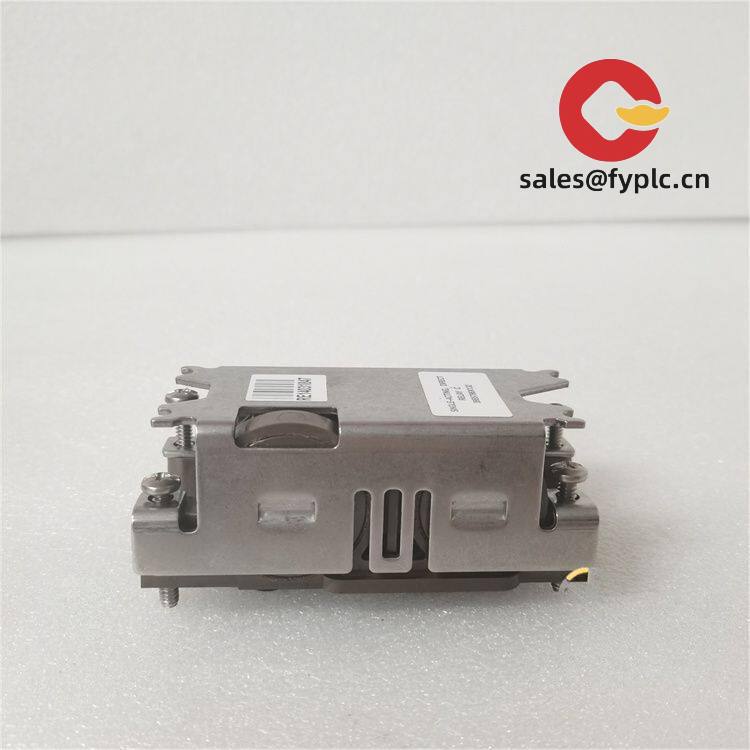

Emerson 38B5786X132 – Fisher OEM Mounting/Adapter Kit for Actuator–Positioner Integration

The Emerson 38B5786X132 is a genuine Fisher OEM kit typically used to mount or adapt a valve positioner (such as a FIELDVUE unit) to a matching Fisher actuator/yoke. From my experience, these “38B…” kits are selected to fit very specific actuator sizes and linkages, so you get the right mechanical alignment without custom machining or guesswork. If you’re replacing a damaged bracket, standardizing spares, or finishing a new control valve build, this kit helps you get the positioner seated correctly, hold calibration, and minimize commissioning time.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days (OEM quality; covers manufacturing defects)

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Genuine Emerson/Fisher part – Factory-specified kit for consistent fit and traceability.

- Application-matched geometry – Brackets and linkages are sized to the intended actuator/yoke, which helps keep the positioner arm geometry correct.

- Stable positioning – Proper mounting typically reduces vibration-related drift and rework during calibration.

- Corrosion-resistant hardware – Industrial-grade materials and finishes suited for tough plant environments in many cases.

- Complete fastener set – The kit usually includes the bolts, washers, and spacers needed, cutting downtime during changeouts.

- Supports routine maintenance – Easier access for positioner inspection and swap-outs without disturbing the actuator.

Technical Specifications

| Brand / Model | Emerson Fisher / 38B5786X132 |

| Product Type | OEM mounting/adapter kit for actuator–positioner integration |

| HS Code (reference) | 9032.90 (Parts of automatic regulating or controlling instruments) |

| Power Requirements | Not applicable (mechanical kit) |

| Operating Temperature | Follows actuator/positioner rating; suitable for typical industrial ambient conditions |

| Signal I/O Types | Not applicable |

| Communication Interfaces | Not applicable |

| Installation Method | Bracket/bolt-on to specified Fisher actuator yoke or mounting surface (per kit drawing) |

Application Fields

You’ll typically find the 38B5786X132 used where plants standardize on Fisher actuators and FIELDVUE positioners—oil & gas, petrochemical, chemical processing, power generation, pulp & paper, and water treatment. A common scenario is upgrading an aging analog positioner to a digital model, and this kit provides the right mechanical interface so the changeover doesn’t stall.

One customer comment we hear: “The bracket fit first time, no slotting or shims.” That seems to be the point—shorten the path from installation to loop check.

Advantages & Value

- Reliability – Factory geometry helps keep linkage alignment within spec, improving positioner stability.

- Compatibility – Selected to match the actuator/positioner family; reduces the risk of misfit parts.

- Lower installed cost – Less field fabrication and fewer return visits for rework or recalibration.

- Documentation and traceability – OEM part number supports maintenance records and audits.

- Support – We can help verify fitment against your valve tag, actuator model, and positioner code.

Installation & Maintenance

- Preparation: Confirm actuator model, yoke size, and positioner type against the kit drawing. Keep the mounting area clean; protect instrument ports from debris.

- Mounting: Align brackets and linkage per Fisher instructions. Tighten fasteners to the recommended torque; use thread-lock where specified.

- Pneumatics & wiring: Route air tubing and signal cables with proper bend radius and strain relief; avoid vibration points.

- Calibration: After mounting the positioner, run auto-setup or manual calibration. Verify travel limits and feedback alignment across the full stroke.

- Routine checks: Re-check fastener tightness at first shutdown, then during regular PM. Inspect for corrosion and replace any worn linkage parts.

- Firmware and diagnostics: When paired with a digital positioner, consider updating firmware and saving device signatures after installation.

- Safety: Isolate the valve, depressurize air lines, and follow lockout/tagout procedures before work.

Quality & Certifications

- Manufactured within Emerson’s ISO 9001 quality system

- RoHS compliance typically applicable for hardware kits

- When installed with certified Fisher devices, the assembly maintains original approvals (e.g., CE, ATEX, cULus), subject to application

- Manufacturer/OEM warranty practices apply; our sales warranty is 365 days

Quick fitment check tip: share your valve tag, actuator model, positioner model, and mounting orientation. We’ll verify 38B5786X132 against your configuration and advise immediately if a different 38B… kit is the correct match.

Reviews

There are no reviews yet.