Description

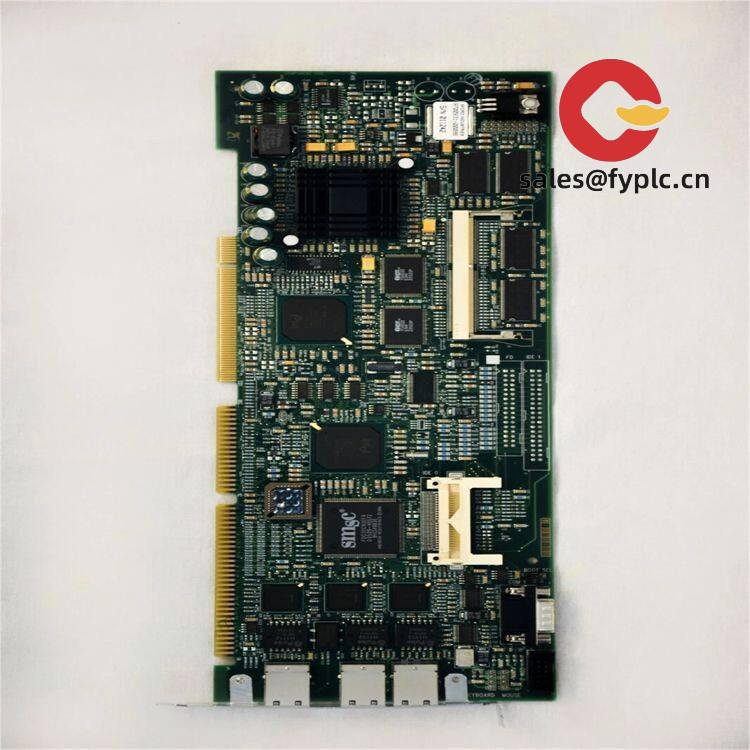

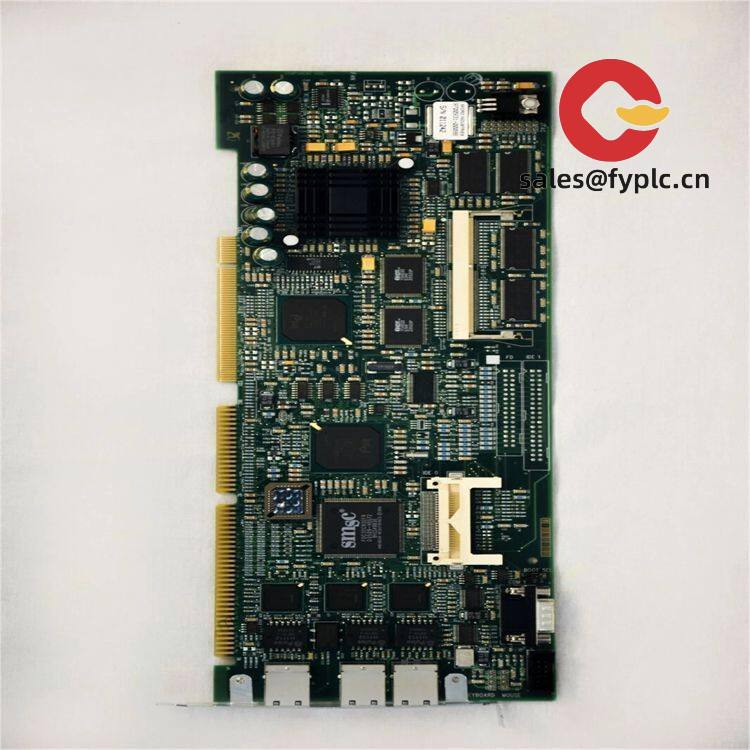

Emerson 5X00105G14 High‑Performance CPU Module – Reliable Controller Core for Ovation DCS Upgrades and Spares

The Emerson 5X00105G14 is a high-performance controller CPU module used in Emerson Ovation distributed control systems. From my experience, it’s favored as a stable, drop‑in replacement in power plants and process facilities that need deterministic scan times, robust redundancy, and clean integration with existing Ovation I/O and engineering tools. You might notice that it’s designed for single‑slot rack installation, which keeps migrations simple and downtime short.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock; no more than one month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express options: FedEx, UPS, DHL

Key Features

- Ovation DCS compatibility: Designed for Emerson Ovation racks and backplanes, keeping existing I/O and graphics intact.

- Deterministic control performance: Consistent scan times for critical loops and logic, typically with stable time base behavior.

- Redundancy support: Pairs with a second CPU for bumpless transfer, so planned maintenance becomes far less disruptive.

- Backplane-powered: No separate power feed; simplifies cabinet wiring and reduces points of failure.

- Flexible communications: Controller network and Ethernet ports, with common integrations to plant historians or Modbus gateways where needed.

- Diagnostics and watchdogs: Front-panel indicators and internal watchdog improve visibility and recovery in most cases.

- Field-upgradable firmware: Updates can typically be performed via the engineering workstation following standard Ovation procedures.

- Long lifecycle spare strategy: Stable hardware platform that seems to be widely stocked for utility and process customers.

Technical Specifications

| Brand / Model | Emerson 5X00105G14 |

| HS Code | 853890 (Parts for industrial control equipment) |

| Power Requirements | Powered via Ovation backplane; 5 VDC nominal, typical consumption < 15 W |

| Dimensions & Weight | Single-slot, approx. 6U rack height; typical weight < 0.6 kg |

| Operating Temperature | 0 to 60 °C (typical), 5–95% RH non‑condensing |

| Signal I/O Types | Controller CPU; field I/O handled via Ovation I/O modules through the backplane (no direct field terminations on the CPU) |

| Communication Interfaces | Controller network ports, 10/100 Ethernet (typical), service/diagnostic serial port; Modbus TCP commonly via gateway or designated controller port |

| Installation Method | Plug-in module for Ovation rack backplane; supports redundant pairing for high availability |

Application Fields

Typically deployed in utility and process automation where deterministic control matters:

- Power generation (coal, gas, combined cycle, biomass) – turbine auxiliaries, boiler controls, BOP

- Water and wastewater – filtration, chemical dosing, pump stations

- Oil & gas – compressor stations, dehydration, utilities control

- Chemicals and refining – reactor, distillation, utilities, flare systems

- Pulp & paper – digester, recovery boiler, steam systems

A maintenance supervisor at a 2×300 MW plant told us they swapped a failed CPU with a 5X00105G14 during a 20‑minute outage window; once the redundant pair resynchronized, the unit returned to load with no loop retuning. That’s fairly typical when firmware and configuration baselines are prepared in advance.

Advantages & Value

- Reliability: Proven hardware design with watchdogs and clear diagnostics—helps cut mean time to repair.

- Compatibility: Works within the Ovation ecosystem, so graphics, logic, and historian tags usually remain unaffected.

- Reduced downtime: Redundant pairing and plug‑in design enable quick changeouts and staged upgrades.

- Cost control: Extends existing DCS life without a rip‑and‑replace project; spares strategy is predictable.

- Technical support: We assist with pre‑ship testing, firmware matching, and start‑up checks to keep risk low.

Installation & Maintenance

- Cabinet & rack: Install in the designated Ovation rack slot; maintain clear airflow and follow 19‑inch cabinet ventilation best practices.

- Power & grounding: Ensure clean, stable backplane supply; bond cabinet ground and follow plant EMC guidelines.

- Wiring: Keep Ethernet and controller network cables in separate routes from high‑noise power wiring; use shielded, properly terminated cables.

- Redundancy: For online replacement, verify the standby is healthy; match firmware/application versions before switchover.

- ESD & handling: Use antistatic protection when inserting/removing the module; avoid touching connector pins.

- Routine care: Quarterly dust cleaning with dry air, check status LEDs/diagnostics, backup controller configuration after any changes.

- Firmware: Update during planned outages; in many cases, align with the site’s validated baseline to avoid compatibility issues.

Quality & Certifications

- Manufactured under ISO 9001 quality systems (typical for Emerson hardware)

- CE and UL compliance on the Ovation platform level; RoHS conformity for electronic assemblies in most markets

- Supplied with a 12‑month warranty (365 days)

One thing I appreciate is how straightforward the changeover tends to be: confirm the slot assignment, verify redundancy health, and keep a tested configuration image ready. If you want, we can pre‑load the required firmware to match your fleet standard so the card arrives “ready to slot.”

Reviews

There are no reviews yet.