Description

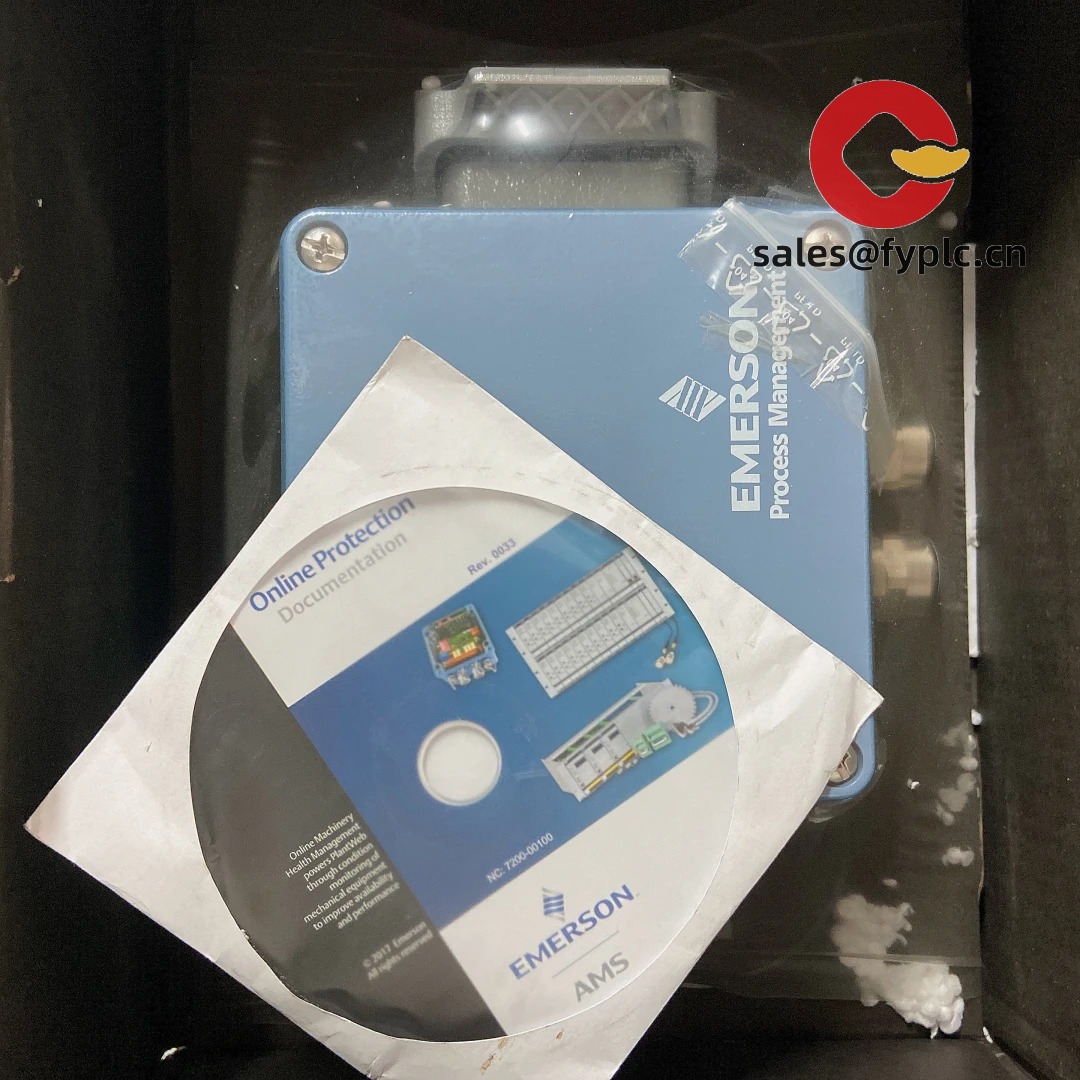

EMERSON A3120022-000 (CSI 3120) – Portable vibration analyzer for route-based machinery health

The EMERSON A3120022-000 appears to be a CSI 3120-series portable vibration analyzer/data collector kit, geared for technicians who need dependable route-based data without dragging a laptop into the plant. From my experience, teams choose this when they want straightforward, repeatable measurements tied into AMS Machinery Manager, plus a rugged handheld that survives long days on the floor. It’s built for rotating assets—motors, pumps, fans, gearboxes—where trending spectra and overall values typically catches issues before they turn into downtime.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Portable vibration data collection – Route-based acquisition of overall values, spectra, and time waveforms for trending in AMS Machinery Manager.

- Dual sensor channels with tach – Typically supports two IEPE/ICP accelerometer inputs and a tach/trigger for speed and phase (useful for balancing tasks).

- Bearing and fault detection tools – Demod/envelope analysis to highlight early-stage bearing defects in many cases before they’re audible.

- Rugged handheld design – Built for field use with gloved operation; you might notice battery life easily covers a normal route.

- Seamless workflow – Simple USB transfer and route sync; minimizes time between collection, diagnosis, and work orders.

- Accessory ecosystem – Works with standard IEPE accelerometers, laser tachs, magnetic bases, and mounting studs to match your machine mix.

Technical Specifications

| Brand / Model | EMERSON A3120022-000 (CSI 3120 handheld vibration analyzer/data collector) |

| HS Code | 9031.80.00 (Measuring or checking instruments; vibration analyzers) |

| Power Requirements | Rechargeable Li‑ion battery; external AC adapter 100–240 VAC, 50/60 Hz |

| Dimensions & Weight | Handheld form factor; typically around 240 × 160 × 60 mm; approx. 1.8–2.2 kg (varies by kit) |

| Operating Temperature | 0 to +50 °C (typical portable analyzer rating) |

| Signal Input/Output Types | 2 × IEPE/ICP accelerometer inputs (BNC), 1 × tachometer/trigger input; headphone/aux out (model dependent) |

| Communication Interfaces | USB device for data transfer and route sync; supports AMS Machinery Manager workflow |

| Installation Method | Field‑portable handheld; used with magnetic bases, adhesive pads, or stud‑mounted accelerometers |

Application Fields

- Refining, chemicals, and midstream – routine routes on pumps, compressors, and cooling fans to flag bearing and imbalance issues early.

- Power generation and utilities – trending turbine auxiliaries, ID/FD fans, and condensate pumps to reduce forced outages.

- Pulp & paper, mining, metals – heavy-duty assets where envelope analysis typically pays for itself with one saved bearing change.

- Water & wastewater – standardize on IEPE sensors and simple routes to keep aeration blowers and lift stations in check.

A maintenance lead at a packaging plant told us their techs picked up a gearbox defect two weeks before a peak run. “Route took 40 minutes with the CSI handheld. We scheduled the repair on our terms,” was his summary—simple but telling.

Advantages & Value

- Proven platform – Emerson’s CSI line is widely used; in many cases it plugs straight into existing AMS workflows.

- Cost control – Route-based monitoring cuts contractor spend and helps avoid unplanned shutdowns.

- Compatibility – Works with standard IEPE accelerometers and common tach sensors, so you can reuse much of your kit.

- Practical support – We can advise on sensor mounting, cable selections, and balancing accessories to shorten your learning curve.

Installation & Maintenance

- Environment – Keep the handheld dry and clean; store in the case when not in use. Avoid direct contact with hot housings.

- Sensors & cabling – Use shielded IEPE leads; clean magnetic bases; apply consistent placement for baseline repeatability.

- Battery & power – Fully charge before routes; carry a spare pack for long shifts. Use the 100–240 VAC adapter in safe areas.

- Calibration – Verify sensors annually on a reference shaker; run the instrument’s self-check before critical data collection.

- Firmware & software – Keep firmware current and synchronize routes with AMS Machinery Manager. One thing I appreciate is the straightforward USB workflow.

Quality & Certifications

- Typical compliance for this category includes CE, FCC, and RoHS.

- Manufacturer coverage varies by region; our supplied units carry a 365‑day warranty.

Recommended Accessories & Add-ons

- IEPE/ICP accelerometers (100 mV/g) with magnetic bases and stud kits for permanent points.

- Laser or optical tachometer probe for speed/phase reference during balancing.

- BNC sensor cables (low-noise) and a compact USB data cable for quick offloads.

- Hard carrying case and spare Li‑ion battery for field shifts.

If you’re mapping out a predictive maintenance program or replacing older collectors, send your asset list and sensor plan. You might notice that a tight bundle—handheld, two accelerometers, tach, and mounts—covers 80% of routine routes with room to grow.

Reviews

There are no reviews yet.