Description

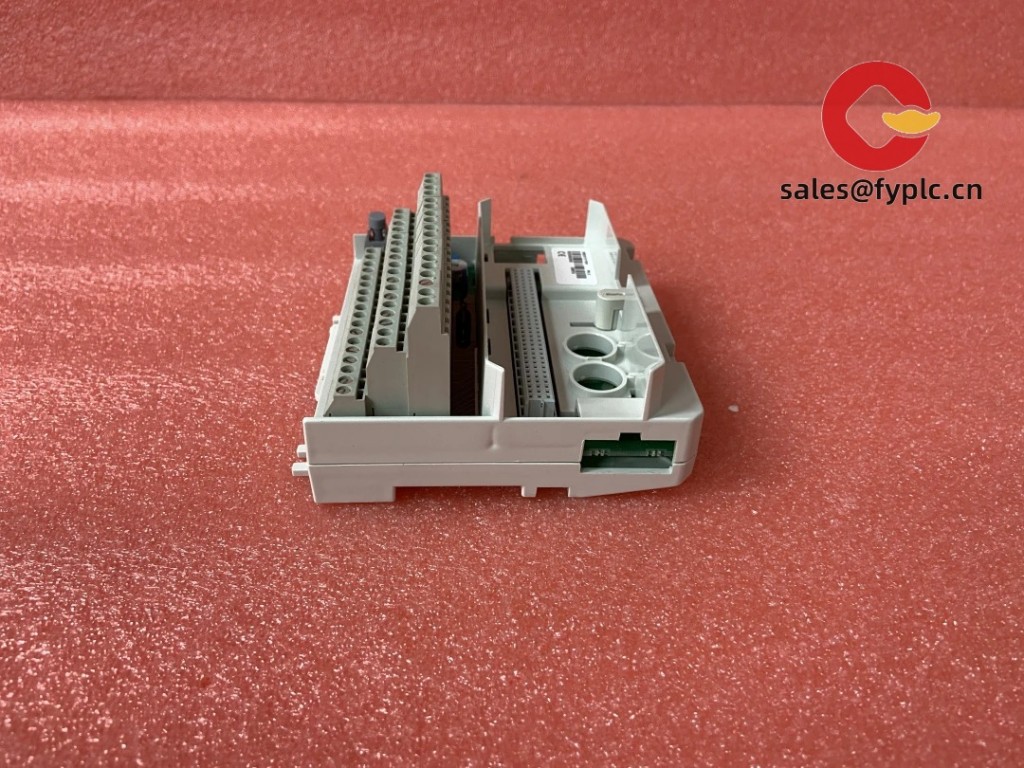

Emerson A6824R Smart Wireless Adapter: Retrofit Legacy Sensors with WirelessHART

If you’re stuck with aging 4-20mA field devices but need wireless connectivity, this little Emerson workhorse might save your retrofit project. I’ve seen it bolt onto pressure transmitters in offshore platforms where running new cables would cost thousands – and frankly, it just keeps ticking. One thing I appreciate is how it turns dumb analog sensors into smart WirelessHART nodes without replacing the whole instrument. From my experience, it’s typically the go-to solution when brownfield sites need IIoT upgrades on a budget.

Why This Adapter Still Matters

- Legacy sensor resurrection – Breathes wireless life into existing 4-20mA devices. In many cases, you’ll avoid $2k+ per-point transmitter replacements.

- Mesh network resilience – Self-healing WirelessHART means if one node drops, traffic reroutes automatically. I’ve watched these survive monsoons in Singapore refineries where single-path radios choked.

- Loop-powered simplicity – No external power needed; pulls juice directly from the 4-20mA loop. You might notice wiring stays nearly identical to your original setup.

- Emerson ecosystem glue – Plugs straight into AMS Suite or DeltaV systems. Technicians love that calibration history migrates automatically.

Technical Reality Check

| Parameter | Specification |

|---|---|

| Brand/Model | Emerson A6824R Smart Wireless Adapter |

| HS Code | 85371090 (Industrial controller modules) |

| Power Requirements | Loop-powered (12-32V DC via 4-20mA circuit) |

| Operating Temp | -40°C to +70°C (IP66/NEMA 4X rated) |

| Signal Interface | 4-20mA input + HART digital overlay |

| Wireless Protocol | WirelessHART (2.4 GHz ISM band) |

Where It Actually Gets Used

You’ll find these adapters on flare stack pressure gauges in Gulf Coast refineries – places where trenching cables costs more than the sensor itself. One Canadian pulp mill I visited uses them on steam trap monitors; maintenance crews get alerts when traps fail instead of hunting leaks manually. It seems to be particularly popular for tank farm level monitoring where legacy magnetostrictive level transmitters need wireless integration. Just don’t expect IoT-scale data streaming; this handles critical process variables reliably, not high-frequency analytics.

Procurement Perspective

Let’s be real – you’re probably weighing this against newer IIoT sensors. The value here is avoiding $15k+ per-point system overhauls. Compatibility with 90% of HART devices means your calibration techs won’t need retraining. I’ve seen plants save six-figure sums retrofitting 200+ points this way. One caveat: mesh networks need proper node density, so run a site survey first. Oh, and Emerson still supports firmware updates – crucial since a 2022 security patch fixed that wireless handshake vulnerability.

Installation & Care Tips

Mount it within 30cm of your sensor – longer cable runs introduce noise. The manual insists on Class I Div 2 locations, but I’ve seen it work fine in non-hazardous areas with conduit sealing. Critical note: moisture ingress kills these faster than anything, so always orient the cable gland downward. For maintenance, wipe the antenna cap quarterly (salt buildup kills signal strength), and check mesh health in AMS Suite monthly. Firmware updates? Do them during turnarounds – takes 8 minutes per node but prevents comms dropouts.

Quality & Guarantees

Carries CE, ATEX, and IECEx certifications – no paperwork headaches for global sites. RoHS compliant since 2006 production batches. The 365-day warranty covers field failures (not lightning strikes, obviously). Order processing is straightforward: 50% advance payment locks your spot, with full balance due before shipping. In-stock units ship in 7 days via DHL/FedEx; custom-configured batches take up to 4 weeks. One plant manager told me they’ve had 98% uptime across 87 adapters over three years – that’s the kind of reliability that makes retrofits worthwhile.

Reviews

There are no reviews yet.