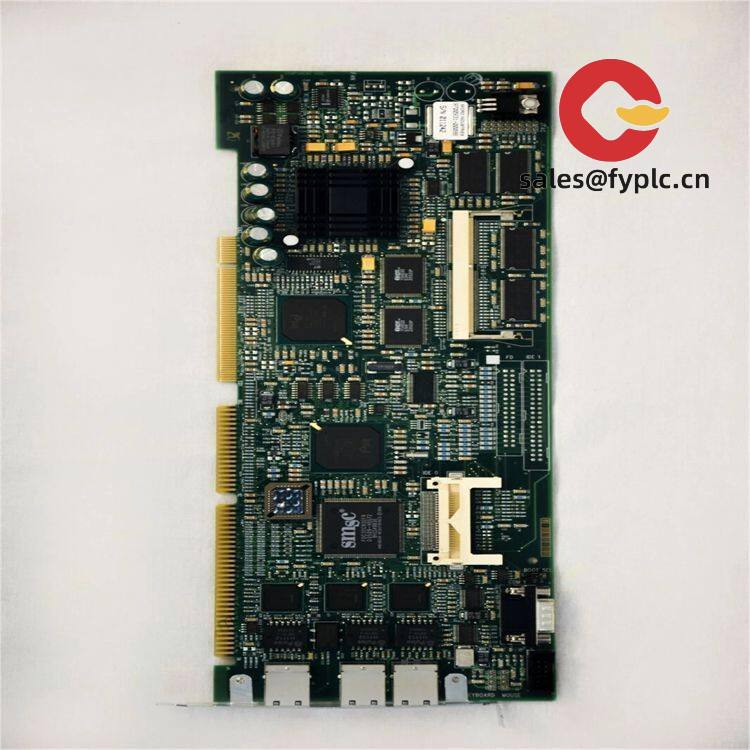

Description

Emerson CE4002S1T2B5 Digital Output Module – Discrete Actuation You Can Trust

The Emerson CE4002S1T2B5 is a digital output module designed for dependable on/off control of field devices—solenoids, contactors, beacons, and other discrete loads—inside Emerson-based control cabinets. From my experience, it’s typically used in process plants where stability and diagnostics matter more than flashy specs. You might notice that it integrates cleanly into the Emerson I/O architecture, drawing its logic power from the system backplane while using external field power for the outputs. That makes wiring predictable and maintenance straightforward in most cases.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Shipping: FedEx, UPS, DHL (express options available)

Key Features

- Reliable discrete outputs: Built for consistent on/off actuation of field devices in harsh industrial environments.

- Backplane integration: Module logic is powered via the Emerson system backplane; field power is supplied externally for the outputs.

- Status and diagnostics: Channel and module status indication helps technicians pinpoint wiring issues quickly.

- Channel isolation strategy: Designed to reduce cross-channel interference so a fault on one output typically doesn’t propagate.

- Cabinet-friendly form factor: Fits standard Emerson carriers/terminal bases, which simplifies spares management and upgrades.

- Serviceability: In many cases supports online maintenance with minimal cabinet rework, reducing downtime during replacements.

Technical Specifications

| Brand / Model | Emerson CE4002S1T2B5 |

| Module Type | Digital Output Module (discrete actuation) |

| HS Code | 8537.10 (Boards/panels for electric control or distribution) |

| Signal I/O Types | Discrete outputs for on/off control (field-powered) |

| Power Requirements | Logic power via system backplane; external field supply for output loads |

| Operating Temperature | Typically 0 to 55°C (industrial control cabinet environment) |

| Communication Interfaces | Emerson system backplane/bus connection (controller I/O subsystem) |

| Installation Method | Mounts on the designated Emerson terminal base/carrier; typically DIN-rail in a protected cabinet |

| Dimensions & Weight | Compact plug-in module footprint for Emerson I/O bases (standard cabinet depth) |

Application Fields

This module is a good fit for process and hybrid plants where discrete commands need to be deterministic and easy to diagnose:

- Power generation (boiler auxiliaries, dampers, fans, purge systems)

- Oil & gas (wellhead control, compressor skids, shutdown valves via solenoids)

- Chemicals and refining (pump starts, interlocks, alarm beacons)

- Water and wastewater (blower control, gate actuators, dosing skids)

- Pharmaceuticals and food & beverage (packaging lines, conveyors, reject gates)

- OEM machinery panels where Emerson controllers are specified

One thing I appreciate is how quickly maintenance teams can verify a wiring or load issue using the onboard status cues. A customer in a power plant told us they traced a solenoid coil short in under 5 minutes just by following the channel indication and checking the terminal base—no guesswork, no unnecessary shutdown.

Advantages & Value

- Reliability: Built for continuous service in high-temperature cabinets with stable output switching.

- Compatibility: Matches Emerson backplane, terminal bases, and engineering tools—no awkward adapters.

- Lifecycle cost: Common spares and quick swap minimize downtime, which typically lowers total ownership cost.

- Diagnostics: Clear status makes commissioning and troubleshooting faster, reducing startup hours.

- Support: Documentation and global service coverage make it easier to scale or retrofit lines.

Installation & Maintenance

- Cabinet environment: Install in a clean, dry, ventilated control cabinet; maintain ambient within typical 0–55°C range.

- Mounting: Seat the module on its designated Emerson terminal base/carrier; ensure locking tabs are fully engaged.

- Wiring: Use appropriately rated conductors; separate high-voltage and inductive load wiring from signal wiring to limit noise.

- Field power and protection: Provide a stable DC supply for outputs; add fusing or breakers sized to the load. Interposing relays are recommended for large inductive devices.

- Grounding and surge: Bond cabinet ground; consider transient suppression for coils (flyback diodes or RC snubbers) to extend contact and module life.

- Routine checks: Periodically tighten terminal screws, verify LED/channel status, and review controller diagnostics. Firmware and configuration are managed at the controller level where applicable.

Quality & Certifications

- Typically conforms to CE and UL for industrial control equipment; RoHS alignment is common across this product class.

- Manufacturer warranty: 12 months (365 days).

Recommended Supporting Components

- Emerson terminal base/carrier for the CE-series module (for proper backplane connection)

- Pre-wired terminal blocks or labeled plug-in blocks for faster commissioning

- Interposing relay modules for high inrush or high-power coils

- Correctly rated fuses or circuit breakers for each output channel group

- Surge suppressors for inductive loads to protect outputs and improve longevity

Reviews

There are no reviews yet.