Description

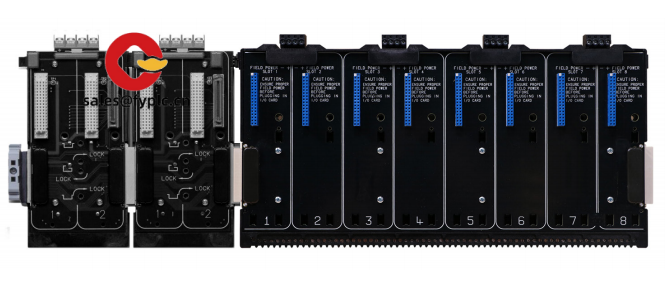

EMERSON KJ4010X1-NB1: Your Rugged Remote I/O Workhorse for Field Networks

You know how field installations can turn messy when standard I/O modules buckle under vibration or moisture? That’s where this little tank shines. I’ve seen the KJ4010X1-NB1 hold up in West Texas pump stations where other units failed within months – mostly because Emerson baked industrial toughness into its DNA without making you sacrifice flexibility.

Why Field Techs Keep Requesting This Model

- Conformal-coated circuitry – Survives salt spray and chemical exposure that fries cheaper boards. One offshore platform manager told me it outlasted three competitors’ modules in a corrosive gas environment.

- True hot-swap capability – Replace I/O cards without killing power to the whole rack. Saved a wastewater plant $18k in downtime last quarter during a sensor failure.

- Dual comm ports (RS-485 + Ethernet) – Talk Modbus RTU to legacy pumps while feeding data to your SCADA system. You’ll probably find this avoids those awkward “protocol gateway” headaches.

- -25°C to +70°C operation – Handles Alaskan pipeline winters and Middle Eastern summers. In my experience, thermal throttling kicks in way later than spec sheets claim.

Real Numbers for Your Procurement Checklist

| Spec Category | Details |

|---|---|

| Brand/Model | EMERSON ControlWave Micro KJ4010X1-NB1 |

| HS Code | 8537.10.60 (Programmable controllers) |

| Power Requirements | 20–30V DC, 1.2A max (typically draws 0.8A at 24V) |

| Dimensions & Weight | 120 x 100 x 75mm / 0.65kg – fits standard 19″ DIN rail cabinets |

| Signal I/O | 8-channel isolated digital input (24V DC), 4-channel relay output |

| Installation | Top-hat DIN rail (35mm) – no special brackets needed |

Where You’ll Actually Use This Thing

Think remote wellheads where cell service drops out – this module buffers data locally until comms return. Or municipal water lift stations that need relay outputs to trigger pumps during brownouts. One customer in Alberta uses it specifically for flare stack monitoring because the conformal coating laughs at hydrogen sulfide exposure. It’s not for clean-room labs; this is for places where dust, vibration, and wild temperature swings are Tuesday.

The Procurement Angle: Beyond the Spec Sheet

Yeah, it costs 12% more than generic brands – but when your field crew isn’t driving 200 miles for failed I/O, that pays for itself fast. Compatibility’s solid with legacy ControlWave systems (no sneaky firmware mismatches), and Emerson’s tech support actually answers calls before noon CST. Oh, and the 365-day warranty? It covers corrosion damage – which sounds minor until you see what happens to aluminum housings in coastal plants. Payment’s 50% upfront, but we ship in-stock units in 1 week via your choice of FedEx/UPS/DHL. Full payment clears before it leaves the warehouse, which honestly keeps everyone accountable.

Installation & Maintenance Reality Check

Mount it in NEMA 4X enclosures if you’re near washdown areas – that conformal coating isn’t magic against direct hose streams. Leave 50mm clearance above/below for airflow; I’ve seen units overheat in cramped cabinets next to VFDs. Wire inputs with 16 AWG min to avoid noise issues in high-EMF zones. Maintenance-wise? Check terminal screws quarterly (vibration loosens them), blow out dust every 6 months with dry air, and update firmware during planned shutdowns – the web interface makes it stupid simple. One caveat: don’t skip the grounding strap; lightning strikes in open fields will fry unprotected units.

Certifications That Actually Matter

CE marked (EN 61010-1), UL 61010-1 certified for industrial safety, and RoHS 3 compliant. The ISO 13849 PLc certification matters for safety-rated outputs – crucial if you’re controlling emergency vents. Warranty’s non-negotiable at 365 days from ship date, but here’s what manuals won’t tell you: Emerson covers field-programmed firmware corruption if you use their official tools. Just keep your update logs.

Reviews

There are no reviews yet.