Description

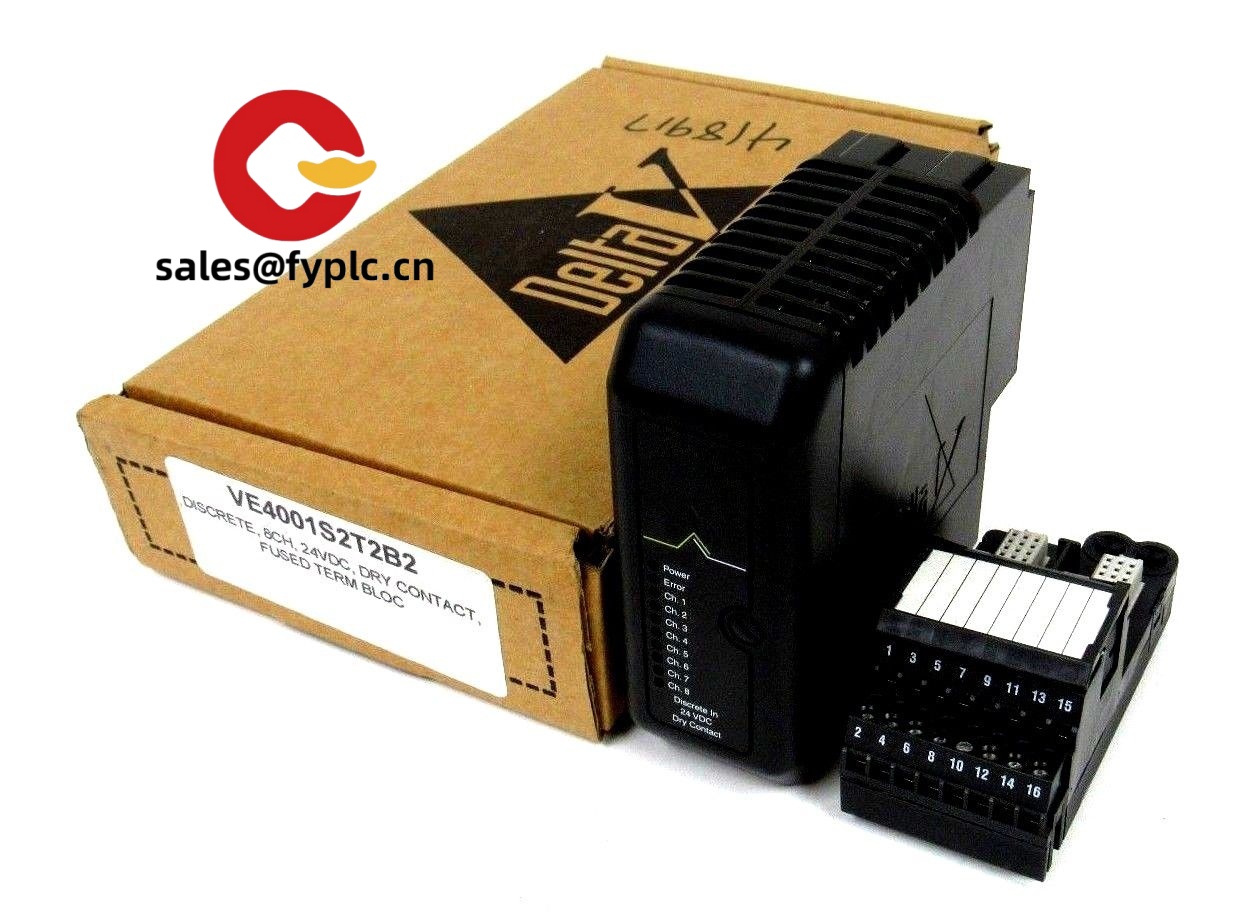

EMERSON VE4001S2T2B2 – DeltaV S-series I/O Base and T2 Terminal Assembly for Reliable Field Wiring

The EMERSON VE4001S2T2B2 is part of the DeltaV S‑series I/O family, used as a robust field‑wiring interface and base assembly for process signals. From my experience, this assembly is chosen when teams want straightforward, serviceable wiring with a removable terminal style (T2) and a sturdy S‑series base (B2) that snaps onto standard DIN rail. It typically pairs with the appropriate S‑series I/O module to handle analog (including HART), discrete, or temperature signals, depending on your application.

One thing I appreciate is how it keeps maintenance simple—techs can access the terminal block without disturbing the backplane, and HART passthrough (when used with HART-capable I/O) makes device diagnostics less of a chore. In many cases, it’s a clean drop‑in for brownfield expansions where cabinet space and wiring time are tight.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- T2 removable terminal block – Clean, serviceable field connections; typically supports rapid swap without re-landing wires.

- B2 S‑series base for DIN rail – Mounts on standard 35 mm DIN rail for fast panel integration and neat cable management.

- Works across common signal types – When paired with the appropriate S‑series I/O module, it supports analog 4–20 mA (often with HART), discrete I/O, or temperature inputs.

- HART passthrough capability – In most cases, HART-capable I/O modules pass device diagnostics to asset management tools without extra wiring.

- Maintenance-friendly design – You might notice that the terminal form factor and keyed connections reduce wiring mistakes and downtime.

- Industrial operating range – Built for typical control-room temperatures and continuous-duty operation in process environments.

Technical Specifications

| Brand / Model | EMERSON VE4001S2T2B2 (DeltaV S‑series I/O base + T2 terminal assembly) |

| HS Code | 8538.90.00 (Parts suitable for 8535/8536/8537; final classification may vary by country) |

| Power Requirements | Powered via the DeltaV S‑series backplane; no separate external power feed to the terminal block (24 VDC nominal system bus, typical) |

| Dimensions & Weight | S‑series 2‑wide profile for 35 mm DIN rail; typical assembly weight under ~0.6 kg |

| Operating Temperature | 0 to +55 °C (32 to 131 °F), typical for DeltaV S‑series installations |

| Signal Input/Output Types | Depends on paired I/O module; commonly supports 4–20 mA (with/without HART), discrete I/O, or RTD/thermocouple |

| Communication Interfaces | Backplane connection to DeltaV controller via S‑series I/O bus; HART passthrough when using HART-capable modules |

| Installation Method | 35 mm DIN rail mounting; T2 terminal style; B2 base assembly |

Notes: Specifications reflect typical S‑series assemblies; confirm exact pairing and channel details against your DeltaV I/O module selection.

Related or Supporting Products

- VE4001S2T2B1 – Similar assembly with alternative base configuration; chosen where cabinet layout differs.

- VE4001S1T1B2 – T1 terminal style for plants standardizing on a different terminal form factor.

- VE4002S2T2B2 – Same family with a different density/type pairing; used when channel count or signal mix changes.

- DeltaV S‑series I/O modules (AI/AO/DI/DO/RTD/TC) – Pair with the VE4001S2T2B2 to achieve the exact signal functionality and HART capability you need.

- DeltaV S‑series carriers and end stops – For neat rail mounting, cable support, and spacing in compact cabinets.

Quick field report: a maintenance lead at a refinery mentioned that swapping to the T2 terminal style reduced their average loop checkout time by ~15% during a turnaround, mostly because the removable blocks made access easier in crowded panels.

Installation & Maintenance

- Cabinet & environment – Install on 35 mm DIN rail in a clean, dry enclosure. Provide ventilation so internal cabinet temperatures remain within 0–55 °C, typically with 20–30% headroom.

- Wiring practice – Separate low‑level analog from high‑voltage or relay wiring. Use shielded twisted pairs for 4–20 mA/HART and ground shields at a single point per plant standard.

- Grounding & bonding – Bond DIN rail and panel ground; keep backplane and shield drains consistent to minimize noise and ground loops.

- Hot‑swap considerations – When the paired I/O allows, modules can be replaced live; follow DeltaV maintenance procedures and verify that channels are inhibited before removal.

- Routine care – Inspect terminal torque or clamp retention during scheduled outages, vacuum dust from enclosures, and review diagnostics in DeltaV/AMS. Firmware updates apply to the I/O modules, not the passive terminal base.

- Safety – De‑energize affected loops when practical. Label and document all terminations; verify polarity and channel mapping before commissioning.

Quality & Certifications

- CE compliant for industrial environments (EMC and LVD, typical for S‑series)

- UL/cUL listed; commonly used in North American control panels

- RoHS compliant (varies by specific build and market)

- Manufacturer warranty: typically 1 year; our coverage: 365 days

Reviews

There are no reviews yet.