Description

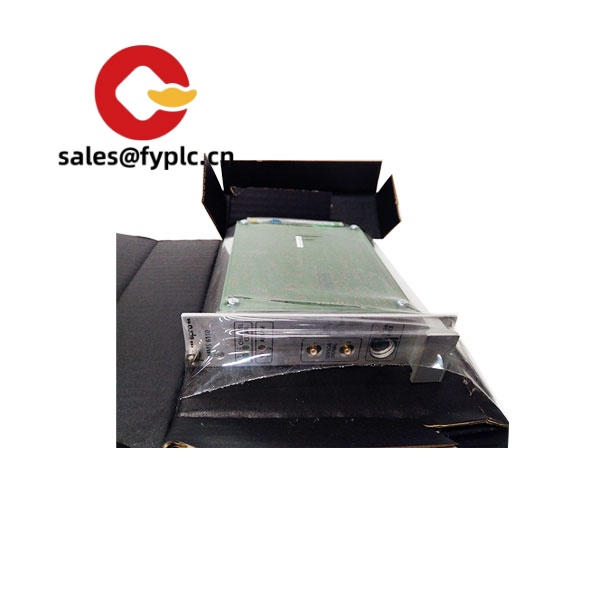

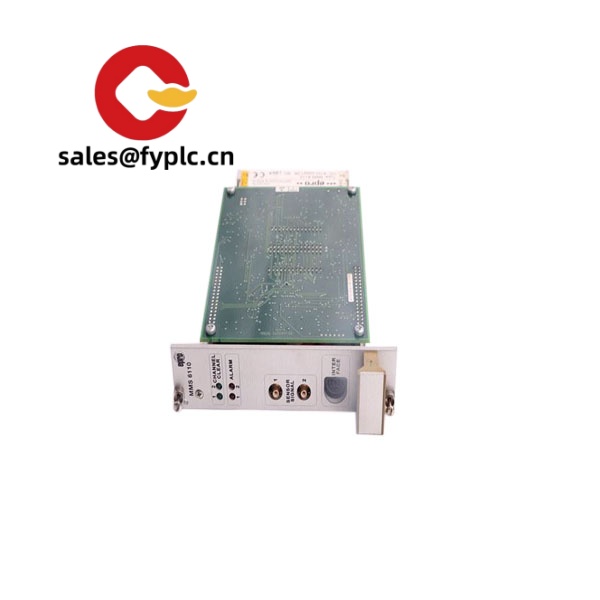

EPRO MMS6110 – Machinery Monitoring Module for MMS 6000 Racks

The EPRO MMS6110 is a plug-in measurement/protection module for the MMS 6000 machinery monitoring system. From my experience, it’s typically used to acquire vibration and position signals on critical rotating assets—compressors, steam/gas turbines, large pumps—then drive alarms and 4–20 mA outputs for the DCS. You might notice that the module’s strength lies in stable measurement, straightforward alarm logic, and clean integration through the MMS rack backplane.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock, no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Built for MMS 6000 racks – Slides into the MMS 6000 backplane for power, communications, and alarm bus. No separate power wiring at the module.

- Vibration and position measurements – Typically supports eddy-current proximity probes for shaft vibration/axial position; many setups also accommodate velocity or IEPE acceleration inputs via system configuration.

- API 670-friendly protection logic – Alert/Danger thresholds, OK channel supervision, and latched alarm behavior to match plant protection practices.

- 4–20 mA per channel – Scaled process outputs so your DCS or PLC sees stable engineering units without extra signal conditioners.

- Buffered signal access – Front-access buffered outputs (commonly BNC) for portable analyzers without disturbing the primary measurement.

- Backplane communications – Data is handed off to the MMS communication module (e.g., for Modbus) through the rack; wiring stays tidy.

- Serviceable in the field – From what I’ve seen, the module is straightforward to commission with clear channel OK indications and simple alarm setup.

Technical Specifications

| Brand / Model | EPRO MMS6110 |

| System Platform | MMS 6000 machinery monitoring rack (plug-in module) |

| HS Code | 903289 (Automatic regulating or controlling instruments; other) |

| Power Requirements | Powered via MMS 6000 backplane; system supply typically 24 V DC at rack level (no direct module power terminals) |

| Signal Inputs | Eddy-current proximity probes for shaft vibration/axial position; many installations also accept velocity or IEPE accelerometer signals depending on configuration |

| Signal Outputs | 4–20 mA per channel (scaled), buffered dynamic outputs (front access), Alert/Danger relay contacts (via module/rack) |

| Communication Interfaces | Through MMS 6000 rack bus to communication/gateway modules (e.g., Modbus via RS‑485 or Ethernet at the system level) |

| Operating Temperature | Typically 0 to +55 °C for normal operation in control cabinets |

| Installation Method | Front-insert, rack-mount plug-in module for 19″ MMS 6000 chassis; field wiring on front-access terminals/connectors |

A maintenance engineer at a combined-cycle plant told us the MMS6110 “saved several hours” during commissioning because the buffered outputs let them validate proximity probe gaps and phase without disconnecting anything.

Related or Supporting Products

- EPRO PR6422 / PR6423 proximity probes – Eddy-current probes commonly paired with MMS modules for shaft vibration and axial position. Choose tip size and extension length to match the application.

- EPRO CON011 / CON021 / CON031 drivers – Probe drivers that condition PR642x probe signals. One thing I appreciate is the stable bias voltage for accurate gap control.

- EPRO MMS6120 – Complementary MMS 6000 module used in many cases for additional process or temperature channels, depending on the rack configuration.

- EPRO MMS6210 (speed/phase) – If you need speed/phase reference for 1X tracking or overspeed trips, this module is typically selected alongside vibration cards.

- Bently Nevada 3500/42M – A functional alternative in sites standardized on 3500; different rack and software ecosystem, but a comparable role for radial/axial measurements.

Installation & Maintenance

- Cabinet & environment – Install in a 19″ MMS 6000 rack inside a clean, dry control cabinet. Aim for ambient 0…+55 °C with moderate humidity; allow airflow around the rack for cooling.

- Wiring & grounding – Use shielded twisted pairs for transducer leads; land shields at a single-point ground. Keep probe/accelerometer wiring separated from high-voltage or VFD cables.

- Proximity probe setup – Set the gap with a feeler gauge or micrometer kit and verify bias voltage (seems to be ~‑10 to ‑20 V typical on many systems). Confirm polarity and scale before enabling trips.

- Alarm configuration – Define Alert/Danger thresholds to your API 670 or site standard. From my experience, enabling time delays (e.g., 3–5 s) reduces nuisance alarms during startups.

- Routine care – Quarterly: check channel OK status, review event logs, wipe dust off the front panel. Annually: verify 4–20 mA scaling, confirm relay function, and back up the rack configuration.

- Firmware & spares – Keep the MMS configuration files and module firmware aligned with your plant’s revision policy. Holding one spare MMS6110 per rack (or per unit) is common practice.

Quality & Certifications

- CE conformity for EMC and safety (industrial environment)

- RoHS-compliant materials in most markets

- Manufactured under ISO 9001 quality systems

- Supplier warranty: 365 days

If you’re replacing a legacy MMS6110, share your rack slot map and probe types. A quick check on scaling, buffered output needs, and relay voting logic usually shortens commissioning—sometimes down to a single shift.

Reviews

There are no reviews yet.