Description

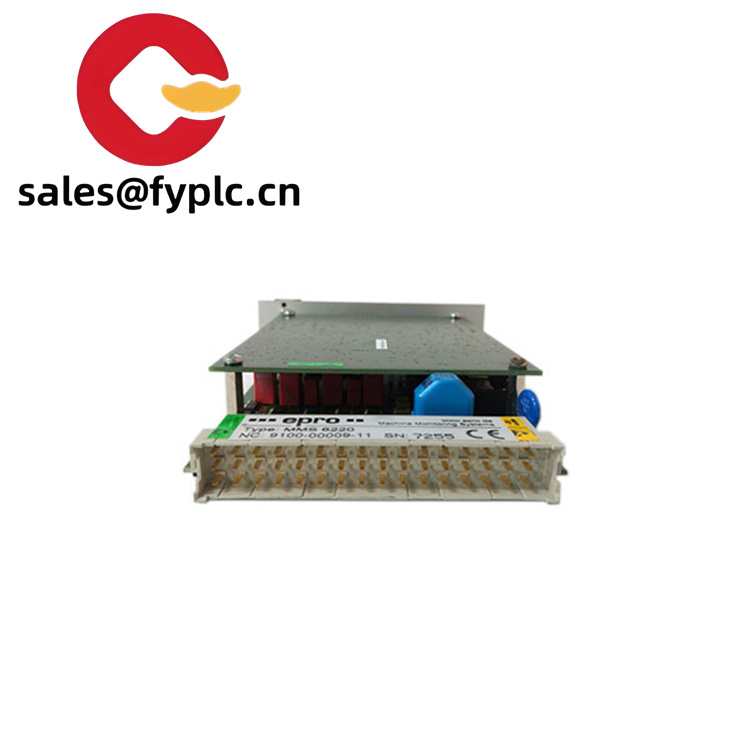

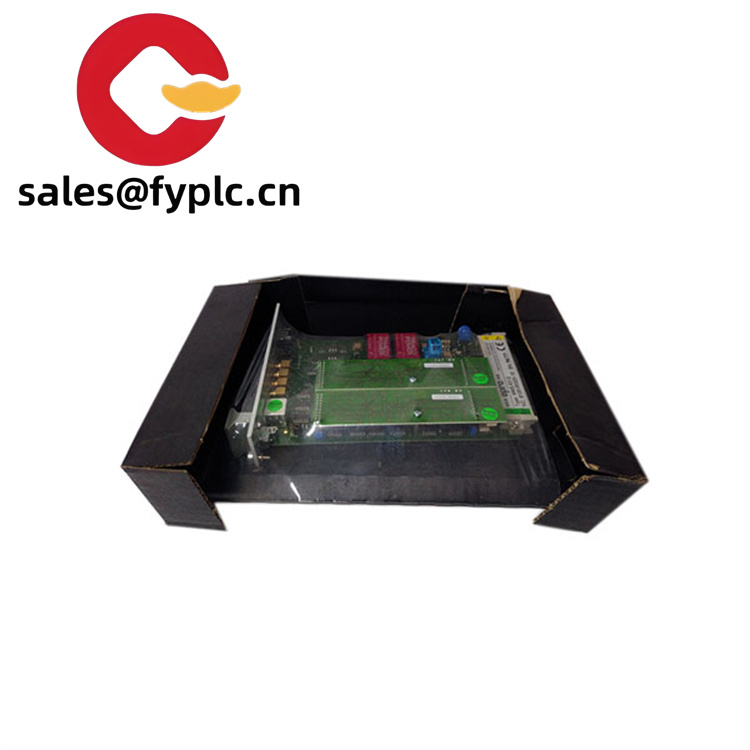

EPRO MMS6312 Dual Channel Shaft Displacement Monitor Speed Plate

The MMS6312 is built for the specific task of precisely measuring the axial displacement of shafts in industrial machinery. Axial displacement, if left unmonitored, can lead to severe consequences, including misalignment, excessive wear, and even catastrophic breakdowns. By continuously and accurately tracking this parameter, the MMS6312 allows industries to take proactive maintenance measures, ensuring the smooth operation of their critical equipment. Whether it’s in power generation plants, manufacturing facilities, or oil and gas refineries, this module acts as a reliable sentinel, constantly watching over the machinery and providing early warnings of any potential issues related to axial movement.

|

Label

|

Specification

|

|

Model Number

|

MMS6312

|

|

Brand

|

[Insert relevant brand if applicable]

|

|

Type

|

Axial Displacement Measurement Module

|

|

Input Voltage

|

[Specify the exact input voltage range, e.g., 18 – 32 V DC]

|

|

Operating Temp

|

[State the operating temperature range, such as -40°C – 85°C]

|

|

Communication Method

|

RS485, Ethernet

|

|

Mounting

|

[Describe the mounting style, e.g., Rack – mountable with secure brackets]

|

|

Weight

|

[Provide the accurate weight value, e.g., 1.5 kg]

|

|

Certifications

|

[Enumerate relevant certifications, e.g., CE, ISO 9001]

|

|

Dimensions

|

[Detail the length, width, and height measurements, e.g., 200mm x 150mm x 50mm]

|

|

IP Rating

|

[Mention the Ingress Protection rating, e.g., IP20]

|

|

Protocols Supported

|

[List the communication protocols, such as Modbus RTU, Profibus DP]

|

For more information, please click on the following link:

AB 2711 series 2711-K6C15 touch screen accessories

Rockwell 1762-OW16 Safety Output Module Relay

Triconex 3009 Enhanced Main Processor (UMP) Module

Triconex 3101/Triconex3201 Triple Modular Redundant Main Processor

AB 2711-K6C5 touch screen human-machine interface function module

Allen Bradley 1769-L32C | Processor Analog Input/Output Module

Reviews

There are no reviews yet.