Description

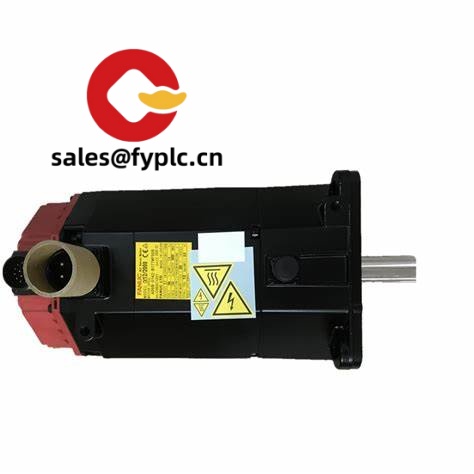

FANUC A06B-0142-B177 – 200V-class α Series AC Servo Motor for Precision CNC Axes

The FANUC A06B-0142-B177 is a proven α-series AC servo motor, commonly used on machining centers and CNC lathes where smooth torque, tight positioning, and drop-in compatibility matter. From my experience, this variant is the “2000 rpm class” motor many OEMs spec for X/Y/Z axes on mid-sized machines. The B177 option typically indicates a straight keyed shaft with a holding brake and FANUC serial pulse coder feedback—ideal for vertical axes and safety-critical stops.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- 200V-class α-series motor – Designed to run with FANUC α/αi servo amplifiers for stable torque and quick response.

- B177 configuration – Typically includes a straight, keyed shaft and an integrated holding brake for vertical axes or safety holding.

- FANUC serial pulse coder – Robust encoder feedback (serial type) for high-resolution positioning and smooth low-speed control.

- Mechanical drop-in fit – Common α-series flange pattern and connector layout helps reduce retrofit time on existing FANUC-equipped machines.

- Industrial protection – IP-rated front end with oil seal options for use in coolant and chip-laden environments (typical machine-tool duty).

- Service-friendly – Clear U/V/W power leads, brake leads, and encoder connector make field replacement straightforward in most cases.

Technical Specifications

| Brand / Model | FANUC A06B-0142-B177 (α-series AC servo motor) |

| HS Code | 8501.52 – Electric AC motors, output >750 W and ≤75 kW (typical classification for this motor class) |

| Power Requirements | 200–240 VAC class via FANUC α/αi servo amplifier (3-phase from amplifier; not connected directly to mains) |

| Nominal Speed (typ.) | 2000 rpm class, suited for positioning and feed axes |

| Dimensions & Weight | α12-class frame; 130 mm square flange is typical for this series; weight commonly in the ~11–14 kg range (confirm exact outline for your machine) |

| Operating Temperature | 0 to 40°C ambient; 85% RH non-condensing (machine-tool cabinet conditions) |

| Signal I/O Types | U/V/W 3-phase motor leads; serial pulse coder feedback; 24 VDC brake leads (for B177); integrated thermal sensor (PTC/thermistor) |

| Communication Interfaces | FANUC serial encoder interface to matching servo amplifier (no Ethernet/fieldbus on the motor) |

| Shaft & Brake | Straight keyed output shaft; integral holding brake (per B177 configuration) |

| Installation Method | Flange mount; horizontal or vertical installation; IP-rated front end with oil seal for machine-tool environments |

Application Fields

You’ll typically find the A06B-0142-B177 on:

- CNC machining centers and drilling/tapping machines (X/Y/Z feed axes)

- CNC lathes and mill-turns (turret or linear axes)

- Robotics and automation fixtures requiring precise, holding-brake-equipped axes

- Retrofits for legacy FANUC α-series systems where fast, drop-in replacement is crucial

One thing I appreciate is how quickly maintenance teams can swap this motor with its like-for-like connectors. A Tier-1 machining line told us they returned a vertical Z-axis to service in under an hour after a planned motor change—zero surprises during homing and backlash checks.

Advantages & Value

- Reliability under load – Built for machine-tool duty; smooth torque delivery at low speed reduces chatter and finish issues.

- Compatibility – Works with FANUC α/αi servo amplifiers and CNC controls commonly found on Japanese and European machines.

- Lower downtime – Mechanical and electrical drop-in fit means less rewiring and fewer parameter changes.

- Cost control – In many cases, reusing your existing amplifier/cables is feasible; no need to redesign the axis drive.

- Technical support – We can share motor outline drawings, connector pinouts, and alignment tips to shorten your maintenance window.

Installation & Maintenance

- Cabinet and environment – Keep the amplifier in a ventilated control cabinet; target 0–40°C ambient, clean/dry air flow.

- Mounting – Ensure the flange face is clean and true; align couplings to avoid radial load on the motor bearings. Use the correct pilot fit.

- Wiring – Route U/V/W power separately from encoder/brake lines; confirm ground continuity. Brake typically requires 24 VDC.

- Safety – Lockout/tagout before handling; the brake can engage suddenly on power loss—support the axis during service.

- Commissioning – Perform zero-return and backlash checks; verify encoder orientation and motor parameters in the CNC/drive.

- Routine care – Inspect connectors/seals, clean chips/coolant residue, and verify cabinet filters. Firmware/parameters on the drive should be backed up after tuning.

Quality & Certifications

- Manufacturing standards: ISO 9001 quality system (manufacturer)

- Compliance: CE and UL for applicable motor families; RoHS alignment typical for current production

- Warranty: 12 months (365 days) from delivery

If you’re replacing an existing α-series motor, share your current amplifier model and machine make. We’ll verify the B177 option set (shaft, brake, encoder) and confirm fit so your team isn’t guessing during installation.

Reviews

There are no reviews yet.