Description

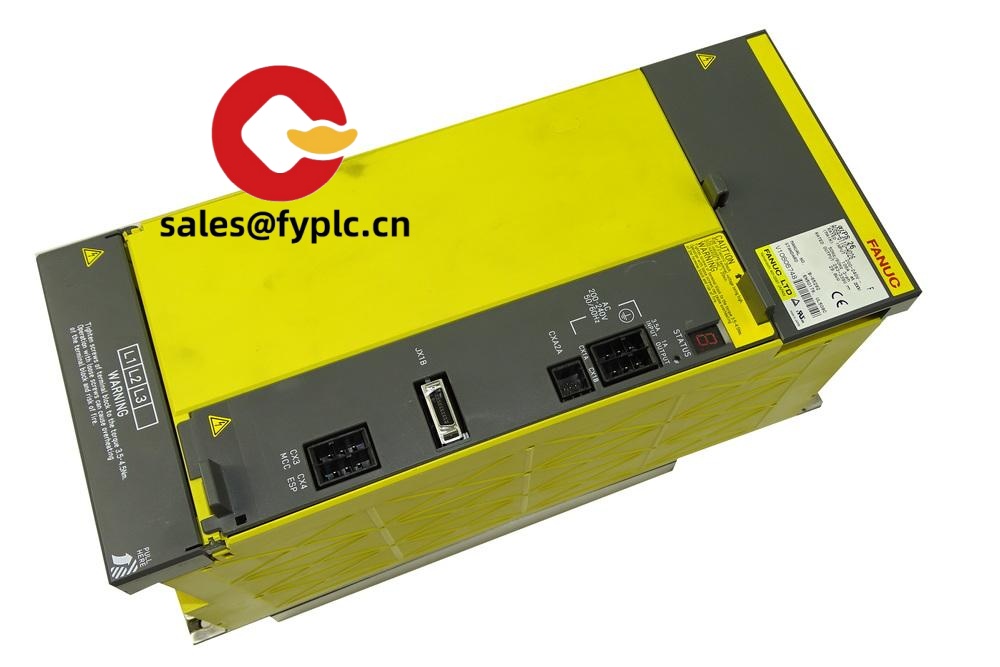

FANUC A06B-6093-H153 – Alpha Series Multi‑Axis Servo Amplifier for CNC Motion Control

The FANUC A06B-6093-H153 is part of the α-series servo amplifier family, widely used to drive multiple CNC axes on machining centers, turning lines, and grinding machines. From my experience, this model is chosen when you want compact, reliable multi‑axis control with FANUC’s FSSB fiber‑optic interface to 0i/16i/18i/21i-series controls. It typically supports multiple servo channels in a single module, helping reduce cabinet space and wiring complexity while keeping performance tight and predictable.

Company’s Order Placement Process and Guarantees

-

- – Warranty: 365 days from delivery

-

- – Delivery: 1 week if in stock; no more than one month at the latest

-

- – Payment terms: 50% advance payment; full balance prior to delivery

- – Express delivery: FedEx, UPS, DHL

Key Features

- Multi‑axis α-series design – Consolidates several servo channels in one module, which in many cases simplifies cabinet layout and reduces parts count.

- FSSB fiber‑optic interface – Direct connection to FANUC 0i/16i/18i/21i controls for fast, noise‑immune communication and straightforward parameterization.

- 200–230 VAC main input – Standard factory power for most CNCs; no unusual transformers needed in typical installations.

- Built‑in regenerative circuitry – Supports dynamic braking; external resistor connection is available for heavier decel loads.

- Diagnostics and alarms – Clear 7‑segment status/AL codes make troubleshooting faster on the shop floor.

- Compatibility with FANUC α servo motors – Works with mainstream α series motor sizes used on machining centers and lathes.

- Compact, panel‑mount form factor – You might notice it fits well in standard CNC electrical cabinets with top‑to‑bottom airflow.

Technical Specifications

| Brand / Model | FANUC A06B-6093-H153 (α-series servo amplifier, multi‑axis) |

| HS Code | 8504.40 (Static converters / servo drive) |

| Power Requirements | Main: 3‑phase 200–230 VAC, 50/60 Hz; Control: 24 VDC (typical for logic/brake circuits) |

| Operating Temperature | 0 to 55 °C, non‑condensing environment, cabinet‑mounted |

| Signal I/O Types | FSSB fiber‑optic link to CNC; motor outputs U/V/W per axis; 24 V brake output; regen resistor terminals |

| Communication Interfaces | FANUC FSSB (fiber‑optic) |

| Installation Method | Vertical panel mounting inside an electrical cabinet with forced ventilation |

| Dimensions & Weight | Compact modular enclosure; typically mid‑size α SVM frame, weight in the ~6–9 kg range (varies by revision) |

Application Fields

You’ll commonly find the A06B-6093-H153 in:

- CNC machining centers – X/Y/Z servo axes with coordinated motion and high feed stability.

- Turning and mill‑turn machines – Smooth contouring with turret or linear axes.

- Grinding equipment – Consistent low‑speed control where surface finish matters.

- Retrofit/expansion projects – Upgrading older cabinets to FSSB‑based α drives without a full electrical redesign.

One thing I appreciate is how predictable the servo behavior is when paired with standard FANUC α motors; commissioning usually goes faster, and maintenance teams tend to feel comfortable with the familiar alarm codes.

Advantages & Value

- Reliability – These modules are known for long service life; in many cases, uptime improves simply by standardizing on this series.

- Compatibility – Works cleanly with FANUC 0i/16i/18i/21i controls and α motors, reducing parameter chasing and unexpected quirks.

- Lower total cost – Multi‑axis in one module cuts mounting hardware and cabling; energy is recovered through regen during decel.

- Supportability – Abundant field knowledge, straightforward AL code diagnostics, and ready access to replacement sub‑components.

A maintenance manager told us their team swapped to this model during a spindle line retrofit and noticed fewer nuisance alarms on rapid decels—seems to be the regen circuit doing its job properly.

Installation & Maintenance

- Cabinet and ventilation – Mount vertically on a flat, grounded panel. Keep top/bottom clearances for airflow; use forced ventilation in warm shops.

- Power and grounding – Supply 3‑phase 200–230 VAC with proper overcurrent protection. Bond PE ground with a short, low‑impedance strap.

- FSSB handling – Keep fiber‑optic bends generous and connectors clean; avoid crushing the cable routing in tight ducts.

- Motor/brake wiring – Size cables to motor current, and verify 24 V brake output polarity before first enable.

- Regen resistor – For aggressive accel/decel profiles or heavy tables, fit the recommended external resistor and mount it where heat can dissipate safely.

- Routine checks – Quarterly dust cleaning, fan inspection, terminal re‑torque, and alarm history review. Back up CNC parameters after any changes.

- Safety – Lockout/tagout before servicing. DC bus can remain charged after power‑off; wait for discharge indicator and confirm with a meter.

Quality & Certifications

- Typically CE marked and UL recognized for industrial control equipment.

- RoHS compliance depends on production year and revision; many late α-series batches comply.

- Manufacturer’s warranty support available; our coverage is 365 days as stated above.

Related/Supporting Components

- FANUC α series servo motors (various frame sizes commonly paired with A06B‑6093‑H153)

- FANUC CNC controls with FSSB (e.g., Series 0i, 16i, 18i, 21i)

- External regenerative resistors matched to decel duty

- 24 VDC control power supplies for brake/logic circuits

- Fiber‑optic FSSB cables and cabinet cooling fans/filters

Reviews

There are no reviews yet.