Description

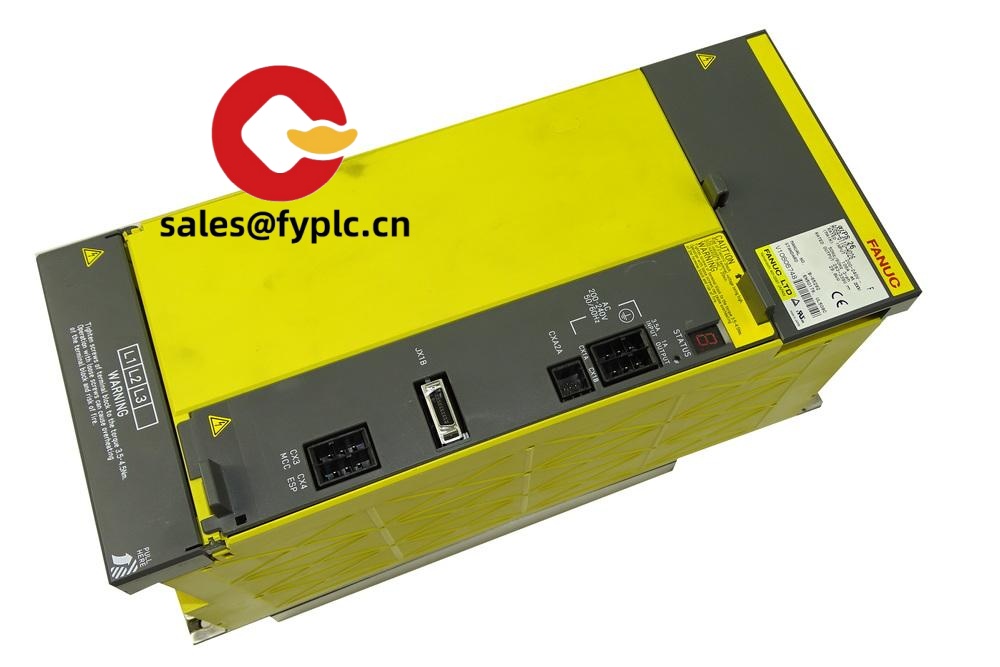

FANUC A06B-6110-H030 αi Servo Amplifier Module – Reliable dual‑axis motion drive for FANUC CNC machines

The A06B-6110-H030 is a FANUC αi Series Servo Amplifier Module (often referenced as GE Fanuc on legacy nameplates). From my experience, this H030 variant is typically deployed as a two‑axis SVM in 200/230 V αi systems, pairing seamlessly with αi servo motors and 0i/30i/31i/32i controls via FSSB fiber optics. If you’re replacing a failed SVM in a machining center or turning cell, this model tends to be a straightforward, drop‑in match—minimal parameter tweaking, fast recovery.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in‑stock items; no more than 1 month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Native FSSB interface – Fiber‑optic FANUC Serial Servo Bus ensures low‑latency, noise‑immune communication with 0i/30i/31i/32i controls.

- Dual‑axis configuration – H030 units are commonly used to drive two servo axes, balancing cabinet space and power density.

- Direct pairing with αi servo motors – Works with αiS/αiF series motors and serial encoders for precise, closed‑loop control.

- Shared DC bus from αi Power Supply Module – Power is delivered via the DC link from an A06B‑6114‑Hxxx PSM; regeneration is handled at the PSM level, simplifying thermal design.

- Protective functions built‑in – Over‑current, over‑voltage, short‑circuit, and thermal safeguards to protect motors and drive electronics.

- Service‑friendly layout – Clear status LEDs, front‑access connectors, and quick fiber replacement speed up maintenance.

- Backwards/legacy compatibility – In many cases, it can replace earlier α/αi SVMs with minor parameter adjustments.

Technical Specifications

| Brand / Model | FANUC A06B-6110-H030 (αi Series Servo Amplifier Module) |

| HS Code | 850440 (Static converters; servo/drive units) |

| Power Requirements | DC bus from αi Power Supply Module (A06B‑6114‑Hxxx), typically ~283–325 VDC; 24 VDC control power; PSM fed by 200–230 VAC 3‑phase |

| Operating Temperature | 0 to 55 °C (non‑condensing, cabinet‑mounted) |

| Signal I/O Types | Motor phases U/V/W per axis; 24 VDC brake control; serial encoder interface for αi motors; status/ready/alarm signals |

| Communication Interfaces | FSSB fiber‑optic link to FANUC CNC |

| Installation Method | Panel mounting inside control cabinet; vertical orientation; bonded to ground backplate; DC bus connection to PSM |

Application Fields

You’ll typically see the A06B-6110-H030 driving X/Y or Y/Z axes in compact machining centers, high‑speed lathes, and small gantry systems. We also see it a lot on:

- Vertical and horizontal machining centers with FANUC 0i/31i controls

- Turning centers with turret and sub‑axis control

- Robotic transfer axes and precision positioning stages

- Packaging and electronics assembly lines retrofitted to αi platforms

“Swapped an H030 into a 0i‑MD mill—fiber, DC bus, motor leads, then a quick parameter verify. Machine was cutting within the hour.” — Maintenance Supervisor, Tier‑2 Automotive

Advantages & Value

- Reliability that reduces downtime – The αi SVM lineage is known for long run‑time and consistent thermal behavior.

- Compatibility – Plays nicely with existing FANUC controls and αi motors; minimal re‑engineering during replacement.

- Cost control – In many cases, a direct replacement avoids rewiring and mechanical changes, cutting labor costs.

- Support readiness – We can help cross‑check motor/axis sizing and FSSB topology to avoid surprises on startup.

Installation & Maintenance Guidance

- Cabinet environment – Mount vertically on a grounded backplate in a sealed cabinet with forced air ventilation; keep ambient 0–55 °C and non‑condensing humidity.

- Wiring – Connect the DC bus and control power from the αi Power Supply Module; route motor U/V/W and brake lines separately from the FSSB fiber to minimize noise.

- Grounding & EMC – Bond motor frames and amplifier PE to a common ground bar; use shielded motor/encoder cables terminated at one end.

- Commissioning – Backup CNC parameters first; verify axis current ratings and motor series match; check LED status and alarms before jog.

- Routine maintenance – Quarterly dust removal (dry air), annual connector re‑seat/inspection; keep firmware and CNC parameters consistent across axes.

Quality & Certifications

- Conforms to CE and RoHS; many builds carry UL recognition when part of the complete FANUC system

- Each unit is function‑tested on representative loads where applicable

- Warranty: 365 days (repair/replace policy, subject to evaluation)

Commonly Paired Components (for planning)

- A06B-6114-Hxxx αi Power Supply Module (PSM) – required DC bus source

- FSSB fiber‑optic cables – CNC to SVM link (short and long runs available)

- αiS / αiF Series servo motors – size per axis torque/current requirements

One thing I appreciate about the A06B‑6110‑H030 is how predictable it is during swaps—you might notice most of the time it’s the cabinet conditions or a loose ground that causes issues, not the module itself. If you want, share your machine model and axis lineup and I’ll sanity‑check the selection before you order.

Reviews

There are no reviews yet.