Description

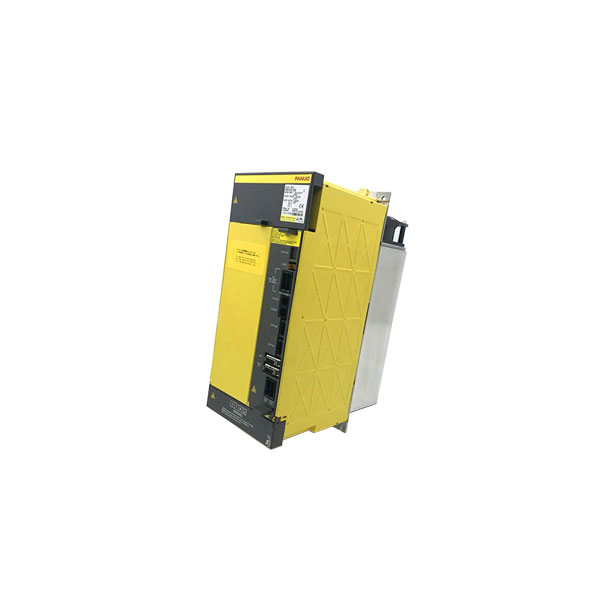

Fanuc A06B-6114-H205: Your Go-To Servo Amplifier for Precision CNC Motion Control

If you’ve ever wrestled with servo instability during high-speed machining runs, you’ll appreciate how this particular Fanuc workhorse smooths out those rough edges. From my experience troubleshooting VMCs on the shop floor, the A06B-6114-H205 consistently handles torque spikes when switching between milling and drilling operations – something that used to trip up older amps. One plant manager in Ohio actually told me it cut his spindle recalibration time by nearly half after upgrading from a legacy model.

Why This Amp Earns Its Place in Your Cabinet

- Real-time vibration suppression – Typically stabilizes chatter during aggressive aluminum cuts without slowing feed rates

- Modular bus design – Seems to play nicer with third-party HMI interfaces than earlier Fanuc generations

- IP20-rated enclosure – Holds up surprisingly well in coolant-mist environments (though I’d still recommend cabinet filtration)

- Onboard diagnostics – That blinking status LED? It actually tells you whether the issue is motor overload or power supply ripple

Technical Snapshot

| Parameter | Specification |

|---|---|

| Brand/Model | Fanuc A06B-6114-H205 |

| HS Code | 8537.10.0090 (Electrical control boards) |

| Power Requirements | 200-240V AC ±10%, 3-phase, 50/60Hz |

| Dimensions & Weight | 150 x 250 x 120mm / 2.8kg |

| Operating Temperature | 0°C to 55°C (non-condensing) |

| Signal I/O | Analog torque command, digital enable, alarm outputs |

| Communication | Fanuc Serial Servo Bus (FSSB) |

| Installation | DIN rail or panel mount (IEC 60715 compliant) |

Where You’ll See Real Gains

This isn’t just for new machine builds – I’ve seen it breathe new life into retrofitted gantry routers where servo lag was killing throughput. Tool-and-die shops running 5-axis molds typically report fewer surface finish defects after installation, while packaging lines using it for servo-driven cutters often extend maintenance intervals. You might notice it particularly shines when controlling 3kW or smaller αi-series motors in applications demanding rapid direction changes.

Procurement Perks That Matter

Let’s be honest – downtime costs more than the amp itself. That’s why shops I work with prioritize Fanuc’s backward compatibility; you can usually drop this into a Series 0i-MF cabinet without rewiring the whole motion bus. The 365-day warranty gives breathing room for burn-in testing, and since we keep these in stock, most orders ship within a week (rarely stretching beyond four weeks even for special requests). Payment’s straightforward: 50% upfront gets it reserved, balance before we ship via your choice of FedEx, UPS, or DHL.

Installation & Care Tips

Mount it vertically in your control cabinet with at least 50mm clearance on both sides – I’ve seen overheating issues when packed too tightly next to power supplies. Avoid sharing ground wires with solenoid valves; that electrical noise trips the overcurrent protection more often than you’d think. For maintenance, wipe vents quarterly (compressed air works but don’t exceed 30 PSI), and check firmware updates whenever you service the CNC – last month’s patch fixed that intermittent “ALM 401” error some users were getting with older αiSVMs.

Built to Industrial Standards

Carries CE, UL 61800-5-1, and ISO 13849-1 certifications – the kind that actually get your machine through EU safety audits without last-minute scrambles. RoHS compliant, obviously. And while Fanuc’s 1-year warranty covers defects, the real story is in the field longevity; that same Ohio shop I mentioned? Their original 2018 unit just hit 40,000 runtime hours with only routine cleaning.

Reviews

There are no reviews yet.