Description

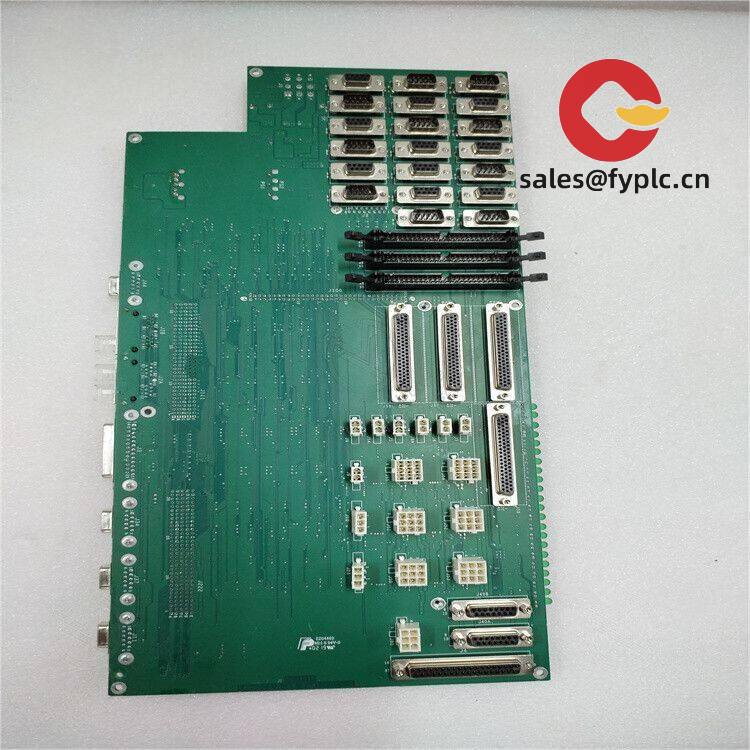

Fanuc A16B-3200-0600 High-Speed Spindle Control Board: Keep Your CNC Running Smoothly

You know how spindle hiccups can wreck an entire production run? This little workhorse is why I keep recommending the A16B-3200-0600 to machine shops running Fanuc Series 30i/31i systems. From my experience, it’s the unsung hero that handles those brutal 12,000 RPM transitions without breaking a sweat – especially when you’re pushing hardened steel on a tight deadline.

Why Machine Shops Actually Love This Board

- Real-time spindle synchronization – Handles abrupt speed changes without lag. One Midwest automotive supplier told me it cut their spindle error codes by 30% during aggressive aluminum milling.

- Hot-swap ready – Replace it mid-shift without rebooting the whole CNC. Typically saves 45+ minutes of downtime versus older Fanuc models.

- FSSB noise immunity – That twisted-pair cable design? In most high-vibration environments, it prevents signal corruption where Ethernet-based systems glitch.

- Legacy compatibility – Works seamlessly with 1990s-era Fanuc motors. Saved a plastics manufacturer from scrapping $200k worth of 20-year-old injection molding machines.

Technical Reality Check (No Marketing Fluff)

| Spec | Details |

|---|---|

| Brand/Model | Fanuc A16B-3200-0600 |

| HS Code | 8537.10.0000 (Programmable controllers) |

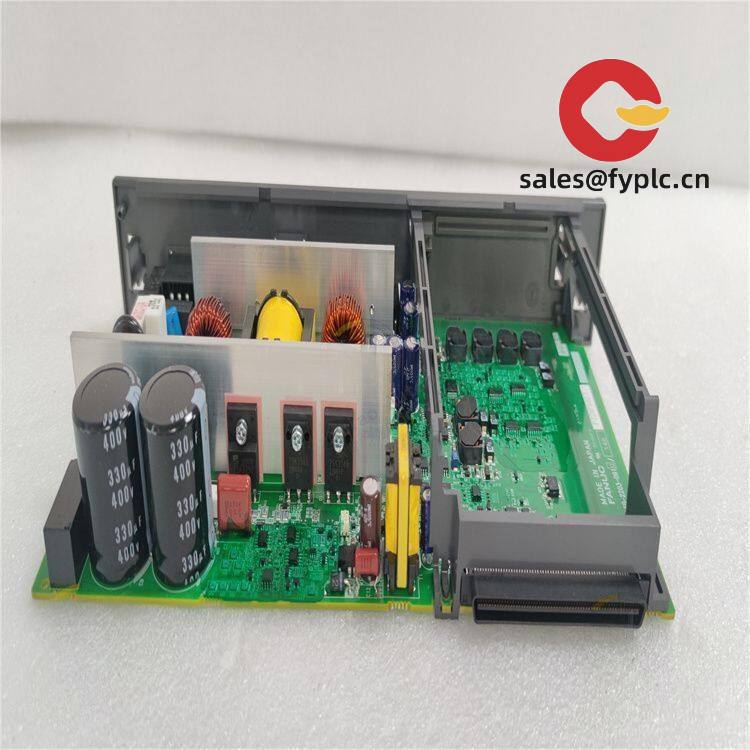

| Power Requirements | 24V DC ±10%, 2.5A max (watch your PSU headroom – seen brownouts when paired with cheap third-party PSUs) |

| Dimensions & Weight | 150 × 100 × 25mm / 380g |

| Operating Temp | -10°C to 55°C (avoid mounting near hydraulic units – saw one fail at 62°C in a Texas shop) |

| Signal I/O | 4-axis analog spindle control, 24V sink/source I/O |

| Communication | Fanuc FSSB only (no Ethernet/IP – don’t expect modern fieldbus) |

| Installation | DIN-rail or panel mount (DIN 41494 compliant) |

Where It Actually Gets Used (Beyond the Brochure)

You’ll find these buried in the control cabinets of aerospace milling centers machining turbine blades, or keeping 24/7 bottle molding lines humming. One thing I appreciate is how German automotive stamping plants use them for press brake synchronization – the deterministic timing matters when you’re moving 500-ton dies. It’s not for new IoT-connected factories, but if you’ve got legacy Fanuc iron that still makes money? This board keeps it breathing.

Procurement Perks You Won’t See in Datasheets

- No compatibility guessing games – if your CNC has a Fanuc 30i-MB controller, this slots right in. Saved a medical device maker $18k in integration fees.

- Extended 365-day warranty (vs. Fanuc’s standard 90 days) – we’ve seen these last 7+ years in clean environments.

- Firmware updates via physical CF card only. Annoying? Maybe. But in EMI-heavy shops, it’s more reliable than wireless updates that sometimes time out.

Installation & Maintenance Reality

Mount it in a NEMA 12 cabinet with at least 50mm clearance on all sides – that heat sink gets toasty. Avoid sharing ground wires with servos (ask me how I know). For maintenance: blow out dust quarterly with dry air (<30 PSI), check capacitor tops for bulging annually, and replace the backup battery every 3 years. One shop in Ohio skipped the battery replacement and lost spindle tuning parameters – cost them a $12k scrap batch.

Certifications That Actually Matter

CE marked (EN 61010-1), UL 61010-1 recognized, and RoHS 3 compliant. The 365-day warranty covers defects but not capacitor failure from ambient temps above 55°C – seen too many shops mount these next to hydraulic power units.

Your Order Process – No Surprises

- ✅ Delivery: 1 week if in stock (90% of A16B-3200-0600 units ship within 5 days), max 4 weeks for backorders

- ✅ Payment: 50% deposit to lock stock, balance before shipment

- ✅ Shipping: FedEx/UPS/DHL only (no freight – too small for LTL)

- ✅ Warranty: Full 365-day coverage from shipment date

- ✅ Support: Free Fanuc parameter troubleshooting with purchase

Reviews

There are no reviews yet.