Description

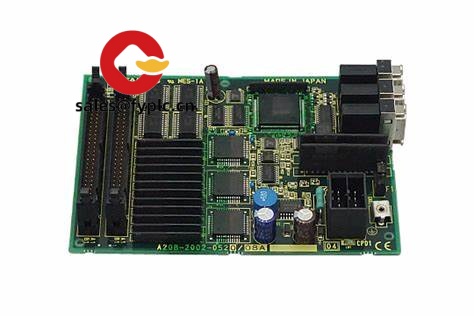

FANUC A20B-2002-0520 – CNC Control PCB for FANUC Systems (Drop‑in OEM Replacement)

The FANUC A20B-2002-0520 is a genuine FANUC printed circuit board used inside FANUC CNC controls. In most cases, this board serves core control and I/O duties within the CNC rack, drawing its power and signals from the FANUC backplane. From my experience, it’s a straight swap when you’re maintaining 24/7 machining lines and need to get the machine back up without re-engineering the cabinet.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Shipping: FedEx, UPS, DHL — export‑ready packing with ESD protection

Key Features

- OEM fit and signal integrity – Designed for FANUC backplane installation, ensuring stable logic‑level signaling and reliable operation under industrial loads.

- Backplane‑powered – No separate power wiring; it typically draws regulated 5 VDC via the control rack, which simplifies service.

- Plug‑in replacement – Swaps directly in the control cabinet with standard card guides and fixing points, reducing downtime.

- Revision awareness – You might notice that suffixes and stickers on the board matter; we verify compatibility against your control model and software level before shipping.

- ESD‑safe packaging and pre‑ship test – Boards are handled and packed with ESD protection; functional tests are performed where applicable.

- Stable in cabinet conditions – Typically suited for sealed CNC cabinets operating around 0–45°C with proper ventilation.

Technical Specifications

| Brand / Model | FANUC A20B-2002-0520 |

| HS Code | 8538.90 (Parts suitable for use with apparatus of 85.37) |

| Power Requirements | Supplied via FANUC backplane; logic 5 VDC (typical) |

| Operating Temperature | 0 to 45°C inside sealed CNC cabinet (typical) |

| Signal Input/Output Types | FANUC system bus and digital logic‑level signals; final field I/O depends on overall control configuration |

| Communication Interfaces | Proprietary FANUC backplane interface; edge connectors to the base unit/rack |

| Installation Method | Plug‑in PCB card; installs on card guides, secured with screws at the rack/front plate |

Note: Functions and connector population can vary by board revision/suffix. We confirm against your control model before shipment.

Application Fields

Typically used in FANUC CNC systems across machining centers, CNC lathes, grinding machines, and EDMs. Many maintenance teams keep an A20B‑2002‑0520 on hand as a spare for fast recovery when axis control or I/O signaling becomes unstable due to board aging or cabinet heat.

A recent example: a Tier‑1 automotive machine shop reported a 30‑minute swap and verification after intermittent I/O alarms. The replacement board stabilized their cycle and the machine was back in production before the next shift.

Advantages & Value

- Reduced downtime – Drop‑in replacement that usually requires no cabinet modifications.

- Compatibility guidance – We match board revisions with your control model and software level, which in many cases prevents avoidable rework.

- Cost‑effective lifecycle support – Extends the service life of installed FANUC equipment without a control upgrade.

- Tested and warranted – Each shipment is function‑checked where applicable and covered by a 365‑day warranty.

- Technical support – Parameter backup advice, swap procedures, and on‑call assistance to help your team complete the changeover safely.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry, well‑ventilated CNC cabinet. Keep filters clean and airflow unobstructed.

- ESD safety – Use grounded wrist straps and ESD mats. Handle the PCB by edges only.

- Power down and discharge – Shut off main power and wait for DC bus discharge before removing/adding boards.

- Back up data – Before swapping, save CNC parameters, PMC ladder, and system data. You might notice this avoids surprises after reboot.

- Seating & connectors – Inspect the backplane connectors; insert evenly until fully seated, then secure with screws.

- Routine care – Periodically clean cabinet dust, check fan operation, and visually inspect for heat discoloration on connectors.

Quality & Certifications

- OEM FANUC part; supplied tested and ESD‑packed

- RoHS/CE/UL compliance is typically determined at the system (machine) level; this board is used within compliant CNC systems

- 365‑day warranty coverage

Commonly Paired Components (for planning and spares)

To keep your line resilient, teams often review these related FANUC parts while replacing an A20B‑series board:

- FANUC A16B‑series Power Supply Units – Stable 5 V/24 V rails are essential for logic boards; aged PSUs can mimic board faults.

- FANUC A06B‑series Servo Amplifiers – If alarms point to axis communication or drive enable, checking the amplifier side alongside the control board saves time.

- FANUC operator panel/keyboard units (A02B‑series) – Intermittent keys or panel I/O can be misdiagnosed as control PCB issues; verifying both helps isolate the root cause.

Reviews

There are no reviews yet.