Description

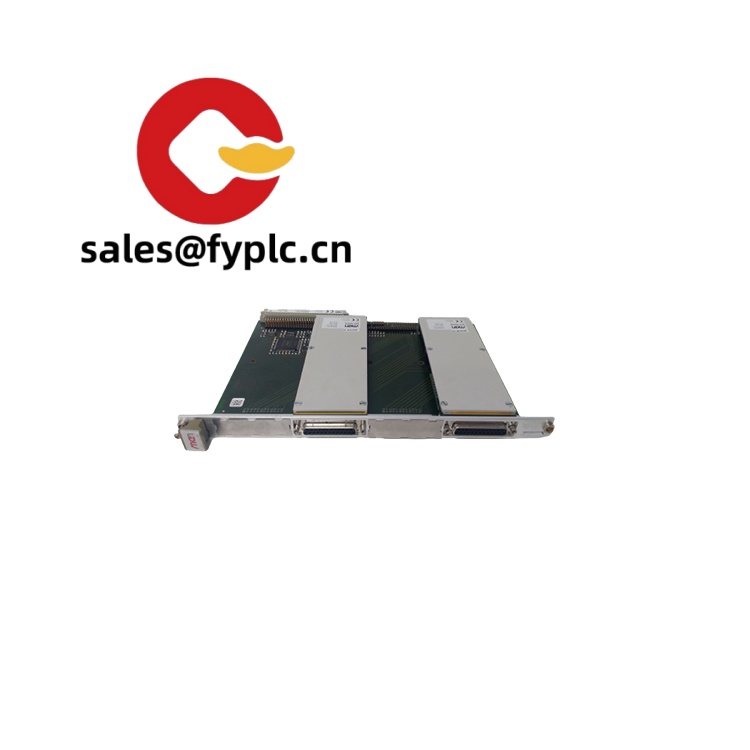

Foxboro A201SR04 / 01A201S12 / 5880-0009 – I/A Series control modules and accessories for dependable plant uptime

From my experience, these Foxboro part numbers are commonly specified as I/A Series plug-in modules and supporting parts used for signal interfacing, power distribution, and interconnect within existing cabinets. If you’re maintaining a legacy Foxboro DCS footprint, the A201SR04, 01A201S12, and 5880-0009 typically slot straight into the original baseplates without any rewiring changes, which is exactly what maintenance teams want during an urgent swap.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Drop-in compatibility – Designed for Foxboro I/A Series baseplates, which typically means no cabinet modifications and shorter downtime.

- Stable operation in control rooms – Built for continuous-duty process environments; seems to be very tolerant of electrical noise when installed with proper grounding.

- Channel isolation where applicable – Many I/A Series modules include galvanic isolation on signal paths to reduce cross-talk and ground loops.

- Backplane communication – Uses the I/A Series backplane, so the controller recognizes the module without external adapters.

- Service-friendly mechanicals – Tool-less latches and keyed connectors help avoid installation mistakes during a quick changeover.

- Lifecycle support – Widely used in brownfield upgrades; keeps your control strategy intact while you plan long-term migrations.

Technical Specifications

| Brand / Model | Foxboro – A201SR04 / 01A201S12 / 5880-0009 |

| HS Code | 9032.89 (Automatic regulating or controlling instruments and apparatus; region-specific classification may vary) |

| Power Requirements | 24 VDC supplied via I/A Series backplane/baseplate (consumption depends on sub-model) |

| Operating Temperature | Typically 0 to +60 °C (control room/cabinet environments) |

| Signal Input/Output Types | Varies by sub-model; commonly discrete 24 VDC, analog 4–20 mA, or relay/contact output on I/A Series channels |

| Communication Interfaces | I/A Series backplane to system controller; no separate external comm port on the module |

| Installation Method | Plug-in to Foxboro I/A Series baseplate/rack inside a ventilated control cabinet |

| Form Factor | Foxboro I/A Series module format; keyed connectors and latching front handle |

Application Fields

These parts are typically used in continuous process industries where system stability matters more than anything: oil & gas (upstream and refining), petrochemical, specialty chemicals, power generation (including combined-cycle), water and wastewater, food processing, and pulp & paper. One thing I appreciate is how they let sites retain existing I/O wiring and sequences, so a plant turnaround doesn’t grow in scope just to replace a single questionable card.

Advantages & Value

- Reduced downtime risk – Drop-in replacement behavior helps shorten maintenance windows and avoid retesting loops.

- Compatibility – Works within the I/A Series ecosystem, so controller recognition and diagnostics are straightforward in most cases.

- Cost control – Keeps your installed base running without a full migration; ideal when CAPEX is tight.

- Documented traceability – Clear part numbers and revision IDs make storeroom management easier.

- Technical support – We can match part revisions, provide installation notes, and share common field tips for these models.

Installation & Maintenance

- Cabinet & environment – Install in a clean, ventilated control cabinet. Maintain ambient temperature within control room range and avoid direct heat sources.

- Wiring & grounding – Use shielded signal cabling where specified; tie shields at a single point. Verify cabinet earth bonding before powering.

- Handling – Observe ESD precautions. Power down the baseplate if the specific slot is not rated for hot-swap in your configuration.

- Commissioning – After seating the module, confirm the controller recognizes the part number and firmware (if applicable). Run a quick loop check for critical I/O.

- Routine care – Visual inspection every shutdown, check terminal tightness, clean dust with dry air, and document any channel deviations. Firmware updates are rare on these, but apply per vendor notice.

Quality & Certifications

- Manufacturing quality aligned with ISO 9001 environments

- CE conformity for industrial control equipment (where applicable)

- UL/CSA component recognition typical for control cabinet installation

- RoHS status may vary by vintage; many legacy Foxboro spares predate RoHS mandates

- Warranty: 365 days functional warranty

Related Supporting Components

To round out an installation, most sites keep baseplate terminal blocks, backplane connectors, and interconnecting cables on hand. If you’re pairing A201-series modules, we can help match the correct baseplate revision, terminal assemblies, and any required ribbon or shielded harnesses so everything lines up on the first attempt.

You might notice that many maintenance teams prefer stocking one complete spare set per critical cabinet. A maintenance lead at a chemical plant told us, “We swapped the card in under 30 minutes and were back on spec without touching the logic,” which, in many cases, is exactly the outcome you want.

Reviews

There are no reviews yet.