Description

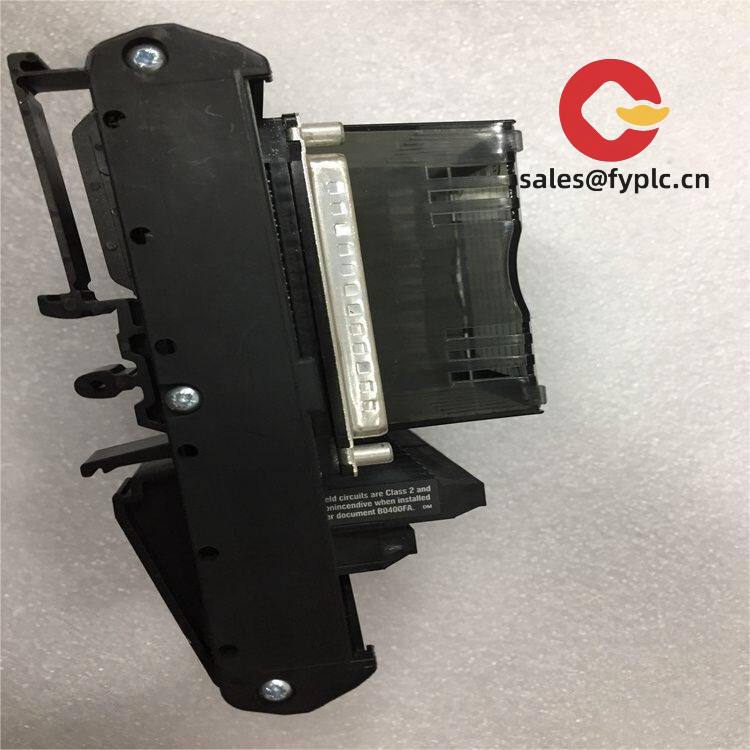

Foxboro FBM207B P0916JS Contact Sense Module – Reliable 16‑Channel Dry Contact Input for I/A Series Systems

The Foxboro FBM207B (part no. P0916JS) is a 200 Series Fieldbus Module designed to sense dry contacts cleanly and consistently. It’s the kind of module you drop in when you need dependable status monitoring for switches, relays, or limit contacts across process units. One thing I appreciate is how it brings internal wetting voltage and noise filtering into a compact, single‑wide form factor—so you get high channel density without fighting for cabinet space. In many cases, it’s paired in redundancy to keep critical interlocks and alarms always available.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express: FedEx, UPS, DHL

Key Features

- 16 dry contact input channels – Ideal for sensing switch closures, relay contacts, and limit switches.

- Internal wetting voltage – Typically provides 24 Vdc, so you don’t need external excitation for contact sensing.

- Debounce and filtering – Reduces chatter from mechanical contacts and improves event integrity.

- Channel diagnostics – You might notice faster troubleshooting thanks to per‑channel status indication.

- Redundancy capable – FBM207B supports redundant pairing on 200 Series baseplates for high availability.

- Hot‑swappable module – From my experience, swap‑outs can be done with process running, minimizing downtime.

- Galvanic isolation – Input-to-bus isolation helps protect the controller from field disturbances.

- Compact single‑wide form factor – Conserves cabinet space and simplifies layout.

- Tight system integration – Native 2 Mbps Module Fieldbus communication within Foxboro I/A Series architectures.

Technical Specifications

| Brand / Model | Foxboro FBM207B (P0916JS), 200 Series FBM |

| Product Type | Contact Sense Module, 16‑channel dry contact digital input |

| HS Code | 853890 (Parts for electrical control equipment) |

| Power Requirements | Powered via 200 Series baseplate; provides internally current‑limited wetting voltage for contact sensing |

| Dimensions & Weight | Single‑wide FBM form factor; approx. 45 W × 225 H × 140 D mm; ~0.6 kg |

| Operating Temperature | Typically 0 to 60 °C; 5–95% RH non‑condensing |

| Signal Input/Output Types | 16 x dry contact inputs, internally wetted (approx. 24 Vdc); per‑channel status indication and filtering |

| Communication Interfaces | Foxboro 2 Mbps Module Fieldbus via 200 Series baseplate to the controller |

| Installation Method | Plugs into 200 Series FBM baseplate; DIN‑rail or panel mounting via baseplate; supports redundant pairing |

Application Fields

This module is typically chosen wherever you need robust contact status collection:

- Oil & Gas: Pump run feedback, wellhead limit switches, ESD contact monitoring.

- Chemical & Petrochemical: Valve limit switches, interlock contacts, annunciation panels.

- Power Generation: Breaker/relay contact status, turbine package switches, permissive contacts.

- Water/Wastewater: Level switch status, door/hood interlocks, pump and blower feedback.

- Pharma & Food: Cleanroom door contacts, equipment safety circuits, conveyor limit switches.

- Pulp & Paper: Machine guards, jam detectors, proximity/contact closures across lines.

A maintenance supervisor told us their redundant FBM207B pair “took minutes to swap, no re‑termination,” which seems to be the norm on well‑kept baseplates.

Advantages & Value

- Reliability you can plan around – Redundant pairing and isolation help keep safety‑critical contacts online.

- Lower installed cost – Internal wetting voltage and high channel density reduce external hardware and cabinet footprint.

- Native compatibility – Works seamlessly with Foxboro I/A Series controllers and engineering tools, saving integration time.

- Serviceability – Hot‑swappable design and per‑channel indication speed up maintenance in most cases.

- Lifecycle support – Widely deployed module with strong availability of spares and technical know‑how.

Installation & Maintenance

- Cabinet and mounting – Install on a 200 Series baseplate mounted to 35 mm DIN rail or panel; allow front clearance for hot‑swap and labeling.

- Environment – Keep ambient within 0–60 °C, non‑condensing humidity; provide ventilation to avoid heat buildup around stacked modules.

- Wiring – Use the designated terminal assembly; segregate I/O signal wiring from power; screened cable for long runs can help with noise.

- Grounding – Bond shields at one end; maintain clean instrument ground to minimize contact bounce noise pickup.

- Safety – De‑energize field circuits before servicing; observe ESD precautions when handling the module.

- Routine checks – Periodically tighten terminal screws, clean dust filters, verify input status via diagnostics, and keep controller/FBM firmware at recommended revisions.

Quality & Certifications

- Certifications: CE and UL/cUL compliant; manufactured under ISO 9001 quality systems; RoHS conformity in many cases.

- Manufacturer’s policy: Typically 1‑year limited warranty; our coverage: 365‑day warranty from delivery.

- Each unit is inspected prior to dispatch to help ensure plug‑and‑play commissioning.

If you’re replacing an existing FBM207 or expanding I/O, the FBM207B P0916JS is a straightforward fit—usually zero surprises during commissioning when the baseplate and controller are in good shape.

Reviews

There are no reviews yet.