Description

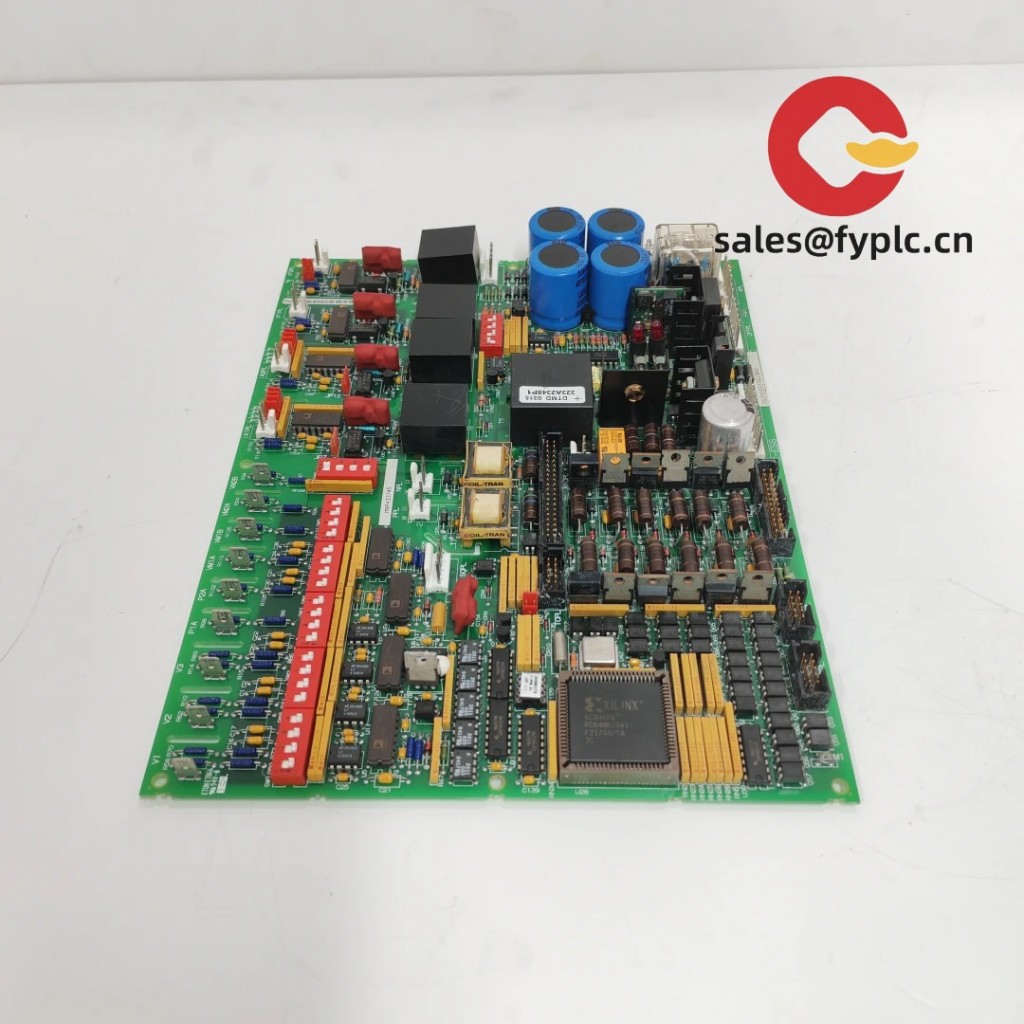

Foxboro FBM217 P0916PW – 8‑Channel Thermocouple/mV Input Module for Precise Temperature Acquisition

The Foxboro FBM217 P0916PW is the kind of I/A Series input module you pick when you need stable, low‑level temperature signals to come into the DCS cleanly and consistently. From my experience, this unit is typically used for multi-point thermocouple and millivolt measurements across process heaters, reactors, and furnaces—anywhere accurate temperature profiling really matters. It slots into the standard 200‑series baseplate, supports hot‑swap maintenance, and seems to be a reliable spare for long-running Foxboro installations where uptime is critical.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express options: FedEx, UPS, DHL

Key Features

- 8-channel thermocouple/mV inputs – Suited for Type J, K, T, E, N, R, S, B thermocouples and low‑level mV signals for flexible temperature coverage.

- Integrated linearization & cold-junction compensation – Reduces external hardware and typically improves accuracy in multi-sensor installations.

- Noise-aware input design – Practical input filtering and stable A/D conversion help in high‑EMI cabinets and near heavy drives.

- Redundant fieldbus architecture – Works within Foxboro’s redundant I/A Series environment; you can hot‑swap the module to minimize downtime.

- Self-diagnostics & channel status – Clear fault reporting helps maintenance teams pinpoint wiring issues or failed probes faster.

- Standard 200‑series footprint – Fits existing baseplates and termination assemblies, which, in many cases, keeps retrofit work minimal.

Technical Specifications

| Brand / Model | Foxboro FBM217 P0916PW |

| HS Code | 8537.10 (Boards/panels for electric control; typical classification for PLC/DCS I/O) |

| Power Requirements | 24 VDC nominal supplied via the 200‑series baseplate; typical consumption < 3 W |

| Signal Input/Output Types | 8 × thermocouple/millivolt inputs (Types J, K, T, E, N, R, S, B; mV ranges typically within ±100 mV) |

| Communication Interfaces | Foxboro I/A Series high‑speed fieldbus via baseplate; supports redundant bus operation |

| Operating Temperature | 0 to 60 °C (industrial control cabinet environment) |

| Installation Method | Plugs into Foxboro 200‑series FBM baseplate; field wiring via matching termination assembly (TA) |

| Dimensions & Weight | Standard single‑width 200‑series FBM form factor; typically under 0.5 kg |

Application Fields

You’ll usually see the FBM217 in temperature‑intensive processes:

- Petrochemical and refining – multi‑point furnace and exchanger thermocouples with mixed sensor types on one module.

- Chemicals and specialty materials – reactor jackets and pilot plant skids where millivolt accuracy matters.

- Power and utilities – boiler and HRSG temperature profiles to support reliability programs.

- Metals & glass – high‑temperature zones with robust noise immunity in harsh electrical environments.

- Pharma & food – validated temperature monitoring with traceable calibration practices.

Advantages & Value

- Drop‑in compatibility – Keeps existing Foxboro cabinets and baseplates in service; typically no re‑wiring of the backplane.

- Lower downtime risk – Hot‑swap capability and clear diagnostics help maintenance finish in minutes instead of hours.

- Lifecycle support – Stable spares strategy for installed I/A Series plants; consistent behavior across FBM families.

- Cost control – Reusing termination assemblies and marshalling reduces project hours on brownfield upgrades.

- Measurement stability – Filtering and CJC/linearization reduce drift and operator “chasing” of temperature loops.

Installation & Maintenance

- Cabinet & environment – Mount in a ventilated control cabinet; maintain 24 VDC supply quality and keep ambient within 0–60 °C.

- Wiring – Use correct thermocouple extension wire, observe polarity, and keep low‑level mV runs away from VFD cables; ground/shield at one end.

- Baseplate & TA – Install on a standard 200‑series baseplate with the matching termination assembly (TA) for T/C wiring and CJC.

- Hot‑swap – Module replacement can typically be done online; follow site MOC and lockout procedures.

- Routine checks – Verify CJC references, perform annual calibration checks with a traceable source, and align firmware revisions with your DCS maintenance plan.

- Spare strategy – Keep at least one spare FBM217 per critical unit; it appears that this reduces mean time to repair significantly.

Supporting Components (Typical Pairings)

- 200‑Series FBM baseplate (multi‑slot) – provides power and fieldbus backplane connectivity.

- Thermocouple termination assembly (TA) – labeled terminals and integrated CJC for clean field wiring.

- Fieldbus/Controller redundancy – used with redundant I/A Series node architecture for high availability.

- Pre‑fabricated interconnect cables – simplifies TA to cabinet marshalling and reduces wiring errors.

One thing I appreciate is how these accessories typically let teams standardize across units—same baseplate, same TAs—so you carry fewer spare varieties and training is simpler for new technicians.

Quality & Certifications

- Conformity: CE marking; UL/CSA recognized for industrial control use (Class I, Div 2 suitability is common on Foxboro FBMs; confirm by revision).

- RoHS: Many units are RoHS compliant depending on manufacturing revision.

- Warranty: 365 days from shipment.

Reviews

There are no reviews yet.