Description

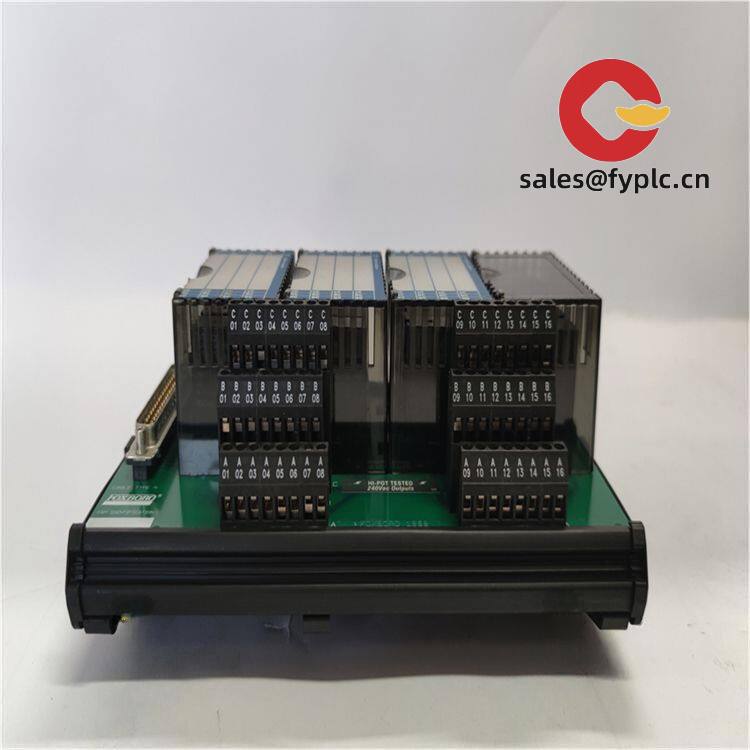

Foxboro FBM218 – HART Communication Redundant Output Interface Module for secure 4–20 mA actuation

The Foxboro FBM218 is designed for control rooms that can’t afford ambiguity on the output side. It provides multi-channel 4–20 mA analog outputs with HART communication and supports redundant configurations, so control to your valves, positioners, and smart field devices keeps running even if one module drops. One thing I appreciate is how it blends straightforward analog actuation with HART diagnostics, so you can command the loop and still read device status without extra hardware.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: Typically 1 week if in stock, no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Shipping: Express via FedEx, UPS, or DHL

Key Features

- Redundant output architecture: Supports paired operation for bumpless transfer in many cases, reducing single-point failures on critical loops.

- Multi-channel 4–20 mA outputs: Typically used to drive valve positioners, I/P converters, and other analog-actuated devices.

- Integrated HART communication: HART pass-through lets you configure and diagnose smart devices without breaking the loop.

- Hot-swappable in Foxboro I/A Series carriers: Replacement can usually be done online to minimize downtime.

- Channel isolation and noise resilience: Designed for industrial environments where ground loops and EMI tend to show up.

- Seamless system integration: Works within the Foxboro DCS architecture, so your engineering effort stays predictable.

- Asset management compatibility: Appears to be compatible with common HART device management tools for remote diagnostics.

Technical Specifications

| Brand / Model | Foxboro FBM218 (HART Communication Redundant Output Interface Module) |

| HS Code | 8537.10 (Programmable control equipment, ≤1000 V) |

| Power Requirements | 24 VDC nominal supplied via Foxboro FBM carrier/baseplate (redundant system power supported) |

| Signal Output Types | 4–20 mA analog outputs (multi‑channel) with HART communication overlay |

| Communication Interfaces | HART pass-through on output channels; backplane connection to Foxboro I/A Series system |

| Installation Method | Mounts on Foxboro FBM carrier/baseplate with field Termination Assemblies (TAs); DIN-rail cabinet mounting of carrier |

| Operating Temperature | Typically 0 to 50°C (control-room environments; check site standards for de-rating) |

Application Fields

From my experience, the FBM218 is a good fit wherever you’re driving analog final elements and want embedded device diagnostics. Typical deployments include:

- Oil & gas (upstream wellhead control, midstream compressor stations, downstream refining)

- Chemical and petrochemical units (valve actuation and reactor utilities)

- Power generation (boiler and balance-of-plant valve control)

- Water & wastewater (RPU dosing skids, blower control)

- Pulp & paper and mining (drive interfaces and process valve loops)

- Pharmaceuticals (utilities and HVAC dampers with HART-enabled positioners)

Advantages & Value

- Reliability: Redundant output capability helps keep loops in control during a module or channel fault.

- Compatibility: Works with most HART-capable valve positioners and 4–20 mA actuated devices; no exotic wiring.

- Lifecycle savings: HART diagnostics cuts blind trips and unnecessary callouts; you typically identify failing devices earlier.

- Maintainability: Hot-swap in the carrier reduces downtime and simplifies spares planning.

- Technical support: Mature Foxboro ecosystem with documentation and field-proven practices.

You might notice that adding HART on outputs doesn’t inflate project risk—most teams keep the same 4–20 mA design and simply enable HART pass-through for device management. A maintenance lead at a midstream gas plant told us their team shaved hours off valve troubleshooting because they could read device status directly through the DCS.

Installation & Maintenance

- Cabinet & environment: Install the FBM carrier in a clean, ventilated control cabinet. Maintain spacing for airflow and avoid mounting near high-heat sources.

- Wiring practices: Use shielded twisted-pair for analog outputs. Ground shields at one end to minimize loops. Verify loop load so that HART communication sees adequate impedance (commonly ~250 Ω in many cases).

- Redundancy setup: When configured in redundant mode, wire outputs and diagnostics per Foxboro guidelines to ensure bumpless transfer.

- Safety: De-energize affected loops before field terminations. Observe intrinsic safety requirements where applicable (use approved barriers if in hazardous areas).

- Routine maintenance: Periodically verify output calibration, inspect terminations for looseness or corrosion, and keep firmware at a qualified revision level for your site.

Quality & Certifications

- CE compliant for industrial environments

- UL/CSA recognized (typical for Foxboro I/A Series modules)

- RoHS compliant where applicable

- Manufacturer warranty practices apply; seller warranty: 365 days

If you’re migrating, the FBM218 is often a straightforward drop-in within existing Foxboro I/A Series infrastructure. Tell me the number of output loops, cabinet conditions, and whether you need full redundancy; I can suggest a practical spares and commissioning plan that avoids surprises during cutover.

Reviews

There are no reviews yet.