Description

Foxboro FBM218 P0917XV Discrete Output Interface Module – Reliable Digital Actuation for I/A Series

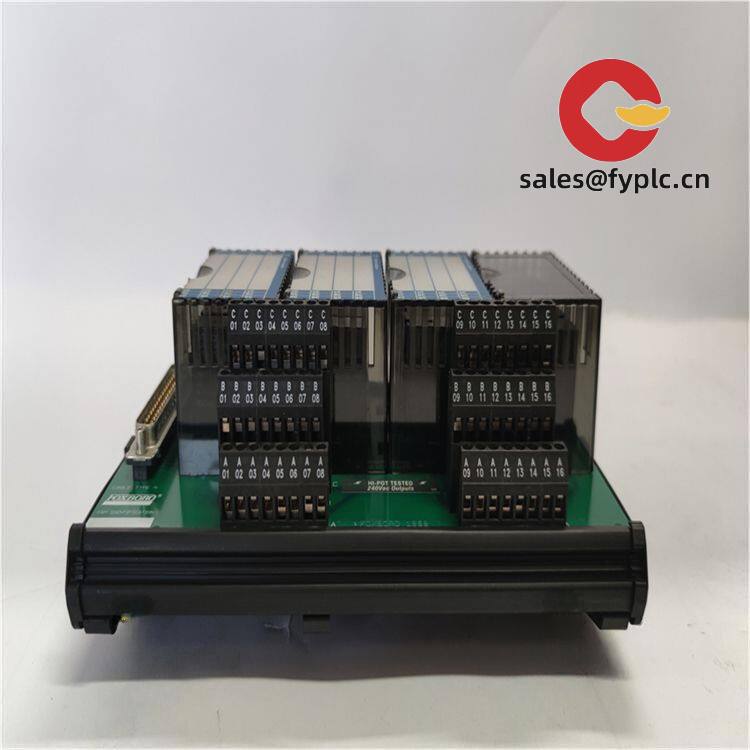

The Foxboro FBM218 (order code P0917XV) is a discrete output interface module used in Foxboro I/A Series and EcoStruxure Foxboro DCS systems to drive on/off field devices—solenoids, interposing relays, lamps, and similar loads. From my experience, the FBM218 is chosen when plants want stable, hot‑swappable digital outputs with robust diagnostics and clean integration through the standard 200 Series baseplate.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment, full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Discrete output channels – Purpose‑built for on/off control of relays, solenoids, beacons, and similar loads in 24 Vdc systems (typical in many installations).

- Hot‑swappable form factor – You can replace the module on the baseplate without shutting down the cabinet; plant downtime stays minimal.

- Bus redundancy – Interfaces through the Foxboro 200 Series baseplate with redundant module fieldbus, which helps continuity during single‑path faults.

- Integrated diagnostics – Health and channel status reporting that typically makes troubleshooting faster at the DCS level.

- Standardized wiring via Termination Assembly (TA) – Clean landing for field conductors, reducing panel complexity and wiring errors.

- Uniform 200 Series footprint – Same mechanical envelope as other FBMs, so cabinet planning is straightforward.

Technical Specifications

| Brand / Model | Foxboro FBM218 (P0917XV) |

| Product Type | Discrete Output Interface Module for I/A Series / EcoStruxure Foxboro DCS |

| HS Code | 8537.10 (Control panels/boards for electric control or distribution) |

| Power Requirements | Powered via Foxboro 200 Series baseplate; no separate logic supply. Field load power supplied per device/TA wiring. |

| Signal Output Types | Discrete (digital) outputs for on/off actuation; 24 Vdc applications are most common; output circuit style per TA/wiring option. |

| Communication Interfaces | Redundant module fieldbus through the 200 Series baseplate (no external comm ports on the module) |

| Dimensions & Weight | Standard Foxboro FBM form factor; one baseplate position; approx. 142 × 47 × 143 mm, ~0.5 kg (typical) |

| Operating Temperature | 0 to +60 °C (32 to 140 °F), non‑condensing environment |

| Installation Method | Plug‑in to 200 Series baseplate; field wiring via matched Termination Assembly (TA); baseplate mounts to DIN rail or backpanel |

Application Fields

Plants use the FBM218 wherever clean, deterministic on/off control is needed. Typical deployments include:

- Oil & Gas: skid packages, valve manifolds, pump start/stop, ESD relay actuation

- Petrochemical & Chemical: reactor interlock outputs, alarm beacons, purge solenoids

- Power & Utilities: breaker status relays, fans/dampers, lube oil skid outputs

- Water & Wastewater: blower/starter relays, gate valves, dosing pump enable

- Pharma & Food: CIP valve islands, conveyor gates, indicator towers

One thing I appreciate is how it behaves predictably with interposing relays; in many cases that keeps the load transients away from delicate cabinet electronics.

Advantages & Value

- System reliability – Redundant bus connectivity and robust FBM design help keep outputs available during single faults.

- Lifecycle continuity – FBM218 fits existing Foxboro 200 Series layouts, so upgrades are usually straightforward.

- Lower integration effort – TA‑based wiring reduces custom terminal work and speeds FAT/SAT.

- Diagnostics that save time – From my experience, clearer module and channel health cuts mean‑time‑to‑repair noticeably.

- Procurement confidence – Traceable sourcing, test records on request, and a 365‑day warranty make it simpler to justify.

Feedback from a packaging line integrator: “Swapping an FBM218 took minutes. We didn’t schedule a shutdown, and the TA wiring stayed untouched—that was the win.”

Installation & Maintenance

- Cabinet environment – Install in a clean, dry, non‑condensing enclosure. Provide ventilation to keep internal temps within 0–60 °C.

- Mounting – Fit the FBM218 into a Foxboro 200 Series baseplate; mount the baseplate on DIN rail or backpanel per panel standards.

- Wiring – Land all field conductors on the matched Termination Assembly (TA). Use interposing relays for inductive or high‑inrush loads when required.

- Grounding & segregation – Separate I/O, power, and communications wiring. Maintain proper shielding and cabinet ground to reduce noise.

- Safety – De‑energize field circuits before maintenance. Verify output states in the DCS and apply lockout/tagout during device changes.

- Routine care – Periodic visual checks for connector seating, TA terminal tightness, and dust removal. Apply firmware/config updates during planned outages when applicable.

Quality & Certifications

- Compliance: CE; typically UL/CSA for industrial control equipment; RoHS alignment in most current builds

- Manufacturing: Made to Foxboro’s 200 Series design standards with module‑bus redundancy

- Manufacturer’s warranty: typically 1‑year limited (varies by region and contract)

- Supplier warranty: 365 days from delivery

Commonly Paired Accessories

- Foxboro 200 Series FBM baseplate (8‑ or 16‑position) for cabinet mounting

- Matching Termination Assembly (TA) for FBM218 discrete outputs and field wiring

- Shielded multi‑core field cables and interposing relays for inductive loads

You might notice that selecting the correct TA option often determines whether outputs are wired as sourcing or via relay isolation—this is where we typically help confirm the right part mix.

Reviews

There are no reviews yet.