Description

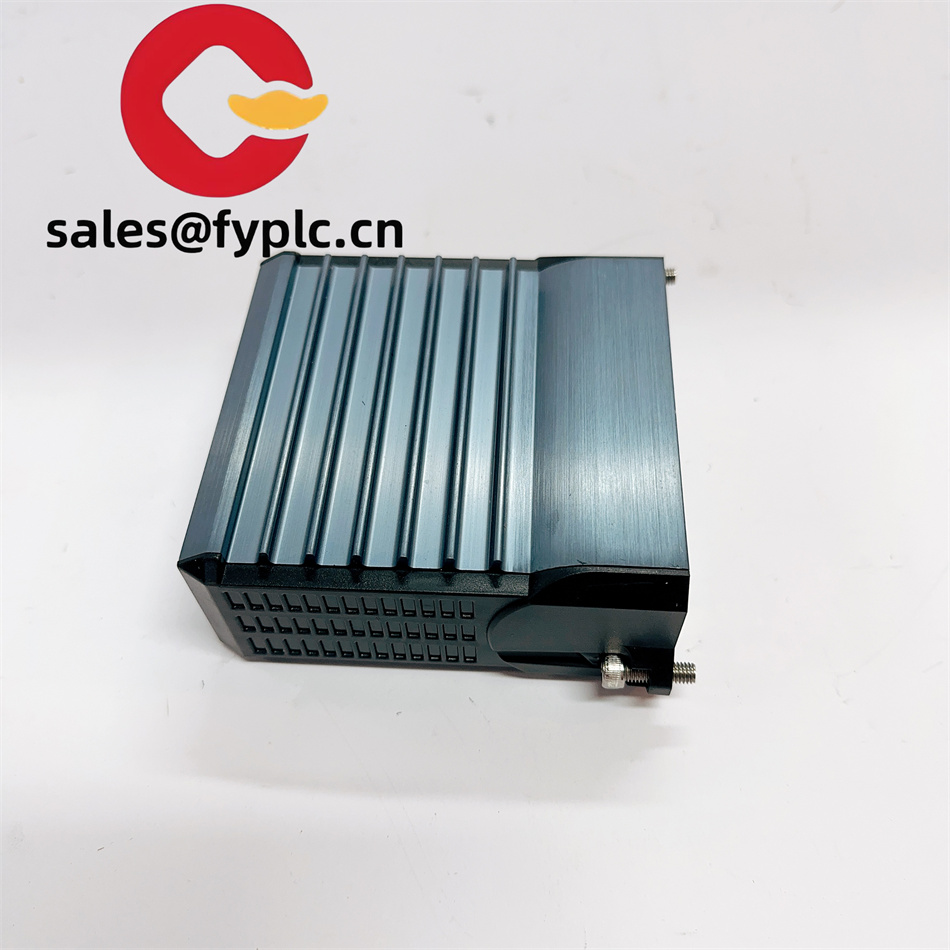

Foxboro FBM232 Input/Output Controller Module

Foxboro FBM232: An Efficient Communication Hub in Industrial Automation

In the intricate architecture of industrial automation, efficient and stable communication between devices is crucial for ensuring smooth production processes, enhancing productivity, and maintaining system safety. The Foxboro FBM232, an outstanding Field Device System Integrator (FDSI) module meticulously crafted by the renowned Foxboro company, demonstrates powerful connectivity and data interaction capabilities across numerous industrial scenarios. It has become a key component in building modern industrial control systems.

1. Core Functions and Exceptional Features

1.1 High – Speed Ethernet Communication

The FBM232 is equipped with a 10 Mbps or 100 Mbps copper Ethernet interface, establishing a high – speed data transmission channel between devices. Whether it’s the real – time monitoring of industrial processes with strict timeliness requirements or the rapid interaction of large – scale data, this module can ensure that data is delivered promptly, significantly improving system response speed and meeting the demand for efficient communication in industrial automation.

1.2 Robust Device Connectivity

By connecting to an Ethernet switch or hub, the FBM232 can communicate with up to 64 external field devices. This feature makes it suitable for industrial projects of all sizes, from small – scale production lines to complex control systems in large factories. It can flexibly build a vast and orderly device communication network.

1.3 Rich Protocol Adaptability

As a general – purpose Ethernet hardware module, the FBM232 can dynamically download I/O software drivers from a rich protocol library. These drivers act like intelligent keys, accurately identifying and adapting to the specific protocols used by devices, such as the common Modbus TCP/IP. This ensures seamless docking between field devices of different brands and types and the control system, enabling barrier – free data interaction and effectively solving the integration problems caused by diverse device protocols in industrial environments.

1.4 Mass Data Processing and Integration

The module supports the connection of up to 2000 Data Communication Interface (DCI) blocks. It can efficiently integrate data collected by field devices, such as various critical information like temperature, pressure, and flow rate, into the Foxboro DCS control database via Ethernet connections. This provides a comprehensive and accurate data foundation for the control system, helping enterprises achieve refined management and in – depth analysis of production processes and providing strong support for optimizing production decisions.

1.5 Durable Design

|

Parameter

|

Specification

|

|

Communication Protocol

|

Uses UDP/IP or TCP/IP for data exchange, widely compatible with various industrial devices and systems supporting these protocols to ensure stable and reliable data transmission.

|

|

IP Address Setting

|

Supports both fixed IP address setting to meet specific network configuration requirements and automatic address assignment via DHCP, simplifying the network deployment process and improving installation and debugging efficiency.

|

|

Supported Data Types

|

Can handle multiple data types, including 2 – byte or 4 – byte signed/unsigned integers, 4 – byte IEEE single – precision floating – point values, and binary values. And it can perform automatic type conversion according to the downloaded driver to ensure accurate data transmission and parsing between different devices and systems.

|

Diverse Industrial Applications

3.1 Manufacturing Industry

On the production line, the FBM232 can connect various sensors and actuators, real – time monitoring equipment operating status, product quality parameters, and other information, and feeding the data back to the control system. For example, by connecting temperature sensors and motor controllers, it can precisely regulate the temperature during the production process to ensure stable product quality; or according to the data from production progress sensors, it can automatically control the start and stop of material conveying equipment, realizing the automation and intelligence of the production process and improving production efficiency and product consistency.

3.2 Power Industry

Used in the monitoring and control systems of power plants, the FBM232 can integrate sensor data from various power equipment, such as temperature, voltage, and current sensors of generators, as well as oil temperature and oil level sensors of transformers. Through the real – time collection and analysis of this data, potential equipment failure hazards can be detected in a timely manner, and maintenance can be carried out in advance to ensure the safe and stable supply of electricity, avoiding power outages caused by equipment failures and reducing economic losses.

3.3 Oil and Gas Industry

During the extraction, transportation, and processing of oil and gas, the FBM232 connects field devices distributed in different areas, such as pressure sensors at wellheads, flow monitors in pipelines, and operation status monitoring devices of compressors. It transmits a large amount of collected data to the central control system, enabling remote monitoring and precise control of the entire production process, ensuring safe and efficient production, improving resource utilization, and reducing production costs.

For more information, please click below to learn more:

Reviews

There are no reviews yet.