Description

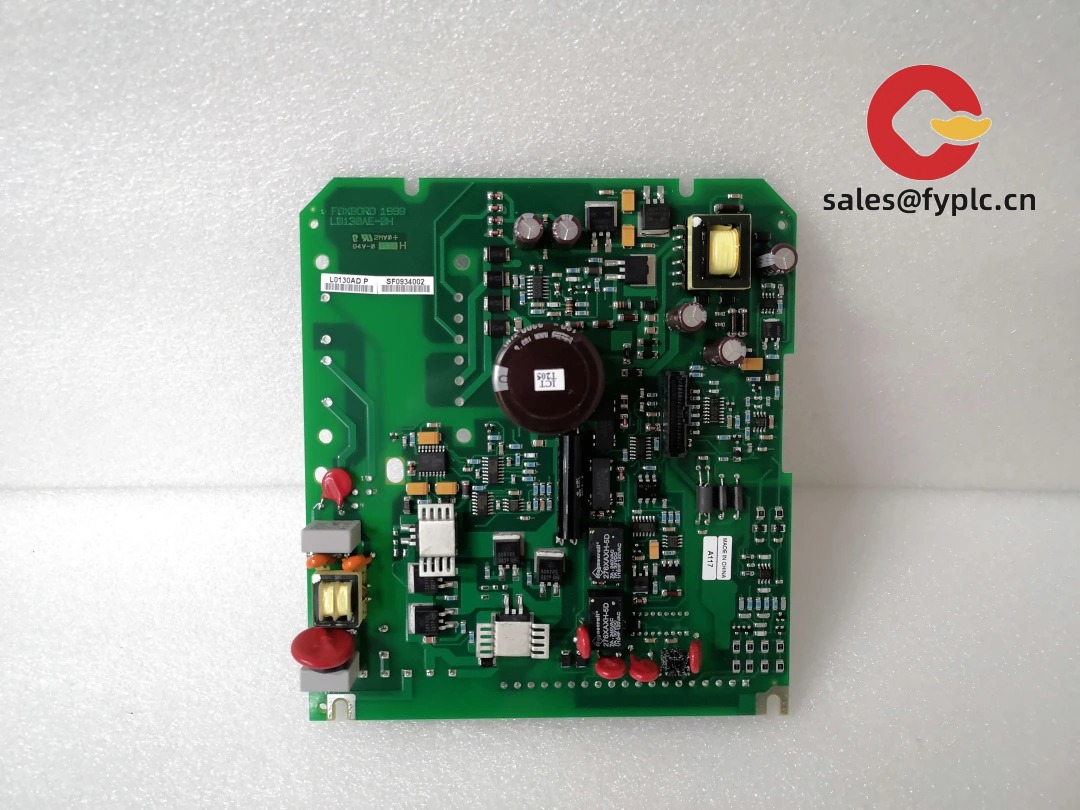

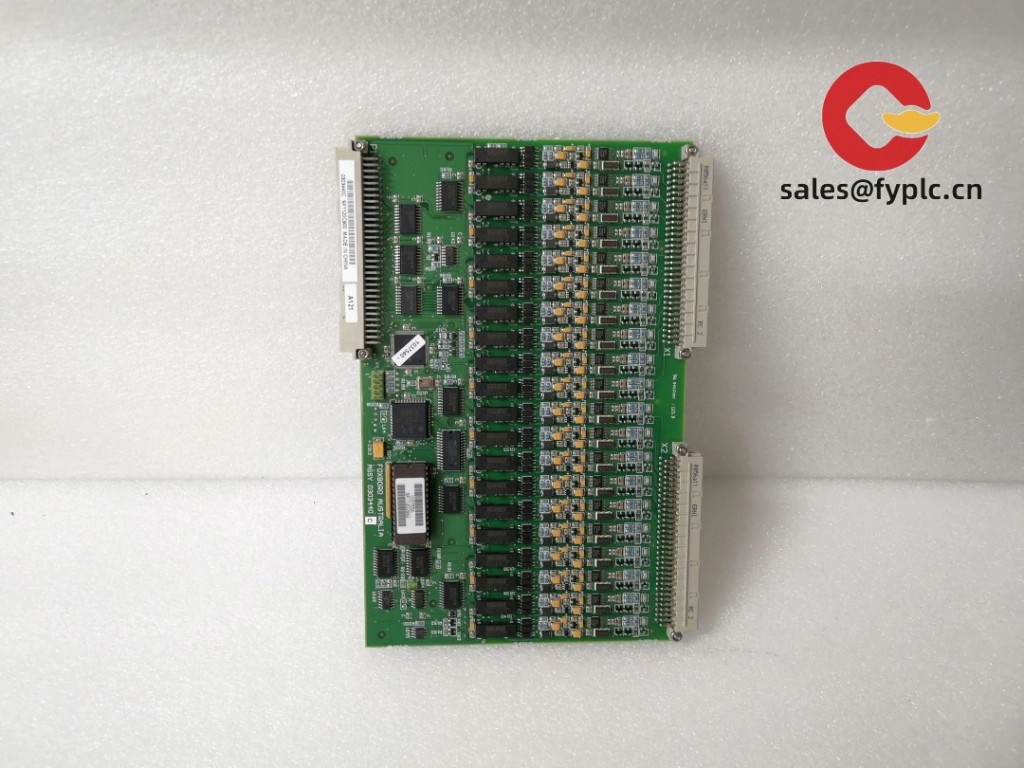

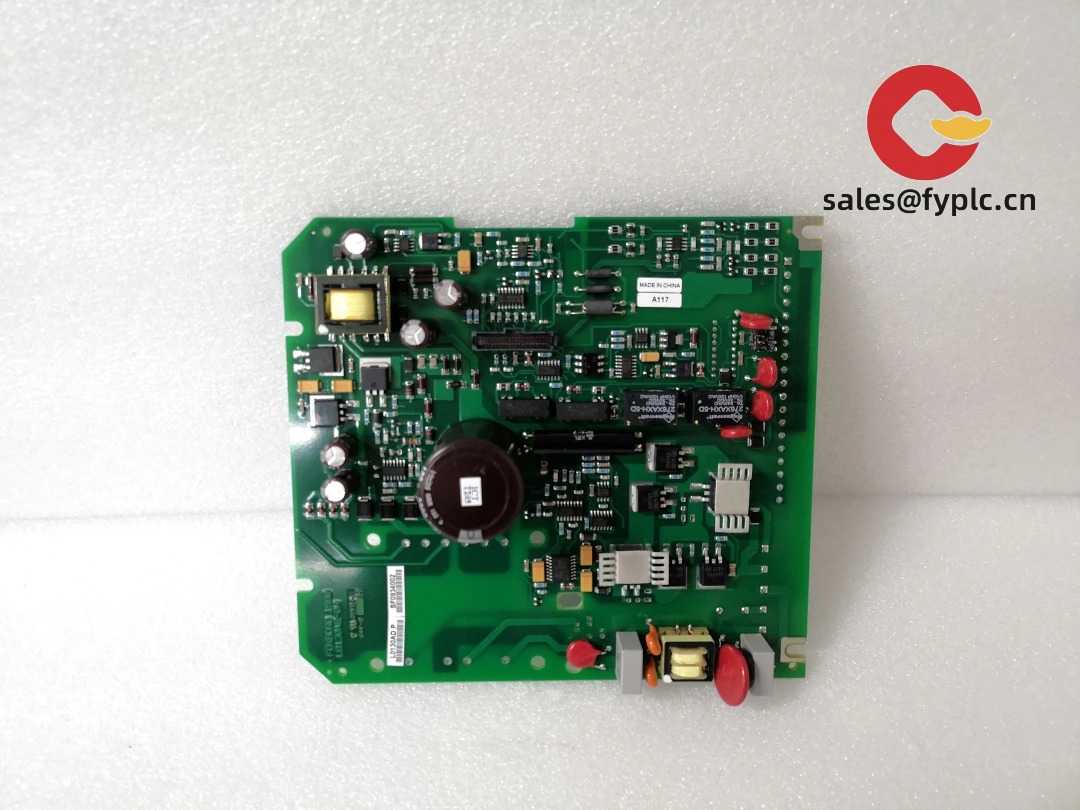

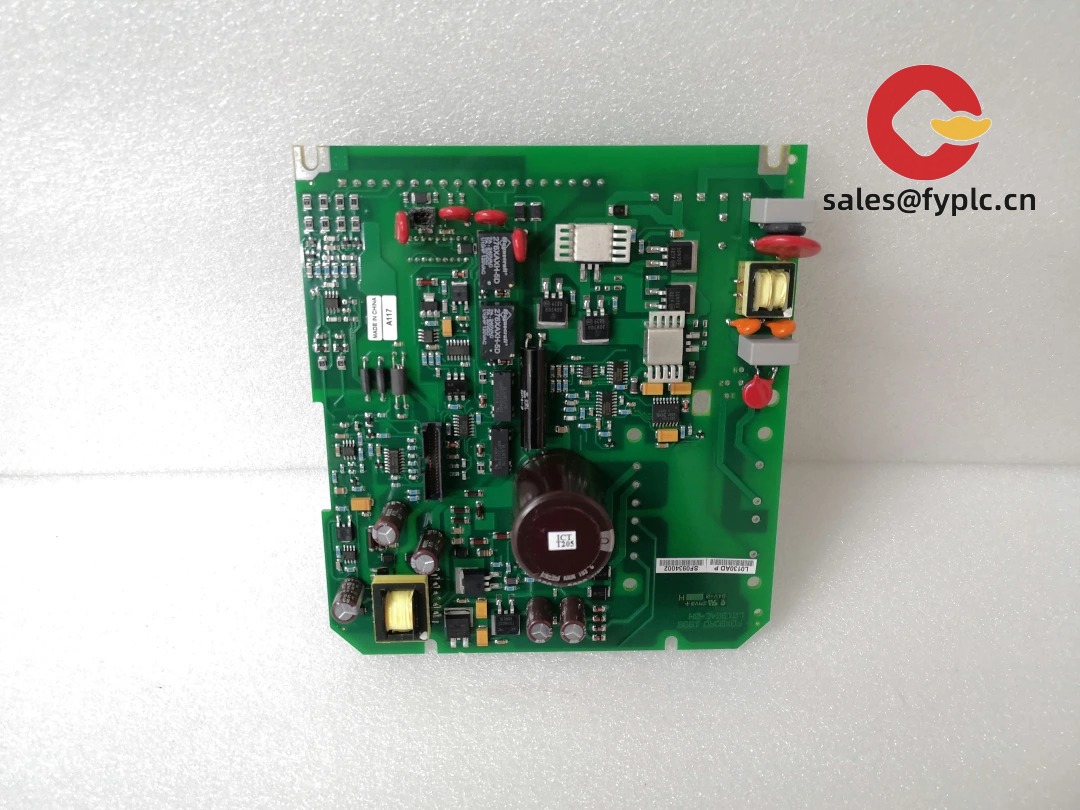

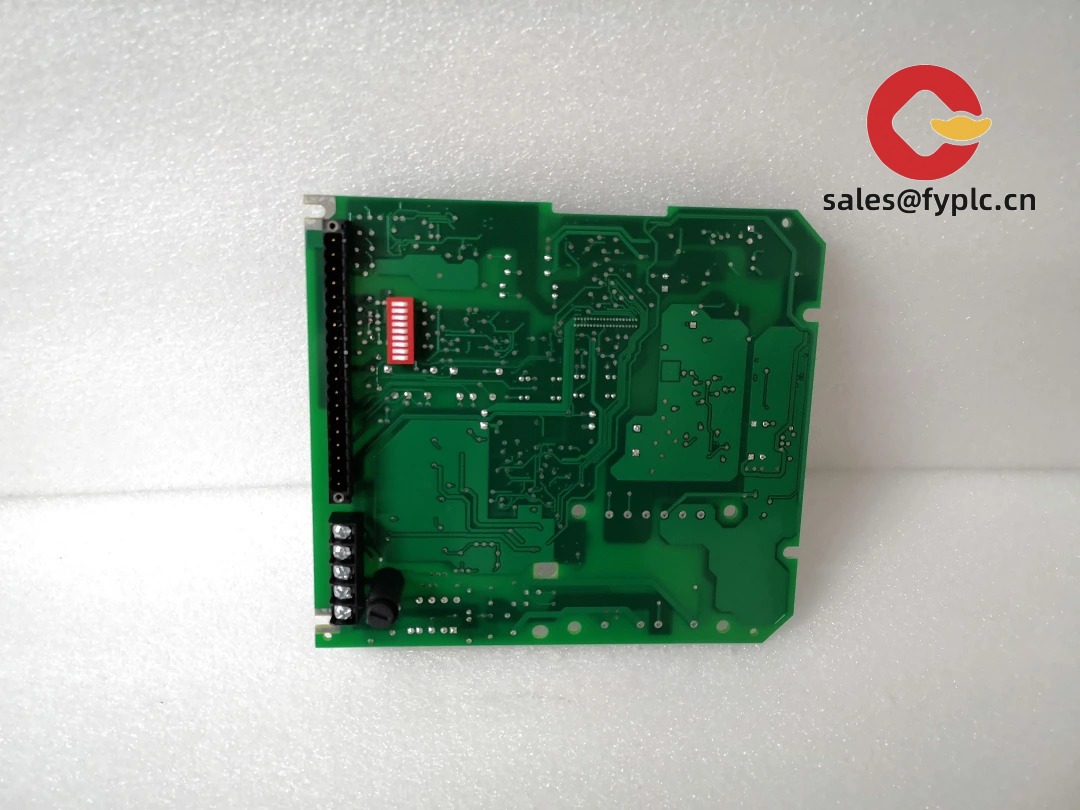

Foxboro L0130AD / L0130AE-0H — Dual-Channel Analog Input Module for Compact I/A Series Nodes

The L0130AD and L0130AE-0H are Foxboro’s compact, DIN-rail–mounted analog input modules designed specifically for smaller-scale or distributed I/A Series applications — think analyzer shelters, remote pump stations, modular skids, or retrofit projects where full-size FBM chassis aren’t practical or cost-effective. Unlike the rack-mounted FBM230/231 family, these modules connect directly to the I/A Series *Node* (e.g., NCM-10, NCM-20) via a dedicated serial link — not the FBM bus — making them ideal for edge-level signal acquisition without expanding the main DCS rack. You might notice they’re often deployed in pairs: the L0130AD handles standard 4–20 mA inputs (e.g., pressure, flow), while the L0130AE-0H adds high-accuracy ±10 V capability for specialty sensors like strain gauges, low-level thermopile outputs, or lab-grade analyzers. From my experience supporting water utility retrofits, this combination shows up frequently when upgrading aging RTU cabinets — delivering DCS-grade reliability at near-RTU price points.

Key Features

- Two isolated analog inputs per module — each channel has 1500 Vrms galvanic isolation, letting you safely mix grounded and floating sources (e.g., 4–20 mA transmitter + ±10 V pH amplifier) on the same device — no external isolators needed.

- L0130AD: Optimized for current loops — supports 4–20 mA and 0–20 mA inputs with built-in loop power (24 VDC @ 30 mA per channel), eliminating the need for separate power supplies in most field wiring configurations.

- L0130AE-0H: High-precision voltage input — offers ±10 V range with 16-bit resolution and ±0.02% accuracy (typical), plus internal cold-junction compensation for direct Type J/K thermocouple connections — something one biotech site used to monitor sterile steam temperature without adding signal conditioners.

- DIN-rail mounted, compact footprint — only 115 × 90 × 65 mm (W×H×D); fits easily into 12″ x 12″ enclosures or crowded analyzer cabinets where space is tighter than budget.

- Node-integrated diagnostics — status appears directly in the I/A Series Node’s diagnostic screen: open circuit, overrange, under-range, and calibration warnings — no need to open the cabinet just to verify health.

Technical Specifications

| Parameter | L0130AD | L0130AE-0H |

|---|---|---|

| Brand / Model | Foxboro (Emerson) / L0130AD | Foxboro (Emerson) / L0130AE-0H |

| HS Code | 8537.10.90 (Control panels for industrial use, other) | |

| Input Types | 4–20 mA, 0–20 mA | ±10 V (also supports Type J/K thermocouples with CJC) |

| Resolution / Accuracy | 16-bit; ±0.05% of full scale | 16-bit; ±0.02% of full scale (±0.5°C for Type J/K) |

| Loop Power (per channel) | 24 VDC @ 30 mA (internally supplied) | Not applicable |

| Isolation | 1500 Vrms (channel-to-channel and channel-to-ground) | |

| Communication Interface | RS-485 serial link to I/A Series Node (NCM-10/20); proprietary protocol | |

| Dimensions & Weight | 115 × 90 × 65 mm (W×H×D); ~390 g | |

| Operating Temperature | -20 °C to +60 °C (derated above 55 °C) | |

Application Fields

These modules thrive where “small but critical” meets “no room for error”: municipal water chlorination skids reading residual chlorine and flow rate; offshore gas compression packages monitoring seal gas differential pressure and bearing vibration; or pharmaceutical cleanroom HVAC nodes tracking humidity and differential pressure across HEPA banks. One wastewater treatment plant in Ohio replaced aging Allen-Bradley 1746-NI4s with L0130AD/L0130AE-0H pairs — the built-in loop power cut wiring time by 60%, and the Node integration meant existing I/A Series logic required zero modification. They’ve logged over 7 years of continuous operation with only one replacement due to physical damage during cabinet repainting.

Advantages & Value

- True DCS integration without rack bloat — appears natively in I/A Series engineering tools (Configuration Manager, Control Builder), with full tag mapping, alarm behavior, and historical trending — unlike generic Modbus RTU I/O that requires gateway configuration and data mapping.

- Reduced wiring complexity and cost — L0130AD’s integrated loop power eliminates two wires per channel; L0130AE-0H’s CJC support removes the need for external thermocouple transmitters — saving ~$120–$180 per channel in materials and labor on typical installs.

- Proven ruggedness in harsh environments — conformal-coated PCBs and IP65-rated housings hold up well in high-humidity, high-dust, or corrosive settings — we’ve seen units operate reliably in coastal desalination plants for over 9 years.

- Faster procurement vs. OEM channels — Emerson’s lead times for L0130 series modules can exceed 10 weeks; we maintain regional stock and ship in-stock units within 1 business day — with full traceability and factory test reports.

Installation & Maintenance

Mount on standard 35 mm DIN rail with ≥30 mm side clearance for airflow. Connect only to I/A Series Nodes (NCM-10/20) using Foxboro-approved shielded RS-485 cable (e.g., FBM-CBL-02). Ground the shield at the Node end only — grounding both ends invites ground-loop noise. For thermocouple use with L0130AE-0H, always use Foxboro’s TBK-100-style terminal blocks with integrated CJC sensors — generic terminals degrade accuracy significantly.

Maintenance is minimal: inspect terminals annually for corrosion (especially in high-H₂S or coastal sites), verify output voltage quarterly (should be 23.8–24.2 VDC for L0130AD loop power), and perform loop checks every 12 months using a certified calibrator. Firmware updates are rare — but if a known Node compatibility issue arises (e.g., timing bug in early v3.1.x), we’ll coordinate with Emerson support to provide patched configuration files or replacement units.

Quality & Certifications

Each module is sourced from Emerson-authorized distribution and carries original Foxboro labeling, factory-etched serial numbers, and full test reports. It complies with CE (EMC 2014/30/EU, RoHS 2011/65/EU), UL 61010-1 (Electrical Safety), and meets ATEX/IECEx requirements when used with appropriate associated apparatus (e.g., MTL788 or Pepperl+Fuchs KFD2-STC4-EX1). Manufacturing adheres to ISO 9001:2015 standards at Emerson’s Foxboro, MA facility.

Warranty is 365 days from date of delivery. If either module fails to acquire valid readings, exhibits inconsistent scaling, triggers false open-circuit alarms, or shows CJC-related drift under normal operating conditions, we’ll ship a replacement the same business day — no RMA required for verified hardware faults.

Our Order Placement Process & Guarantees

- Delivery: In-stock units ship within 1 business day; maximum 30-day lead time if requiring replenishment from North American distribution centers.

- Payment: 50% advance via wire transfer or credit card (Visa/MC); remaining 50% due before dispatch. No net terms.

- Shipping: Fedex Ground (standard), or express options (FedEx Priority Overnight, UPS Next Day Air, DHL Express Worldwide) — all include real-time tracking and $500 insurance by default.

- Documentation: Includes Emerson-documented datasheet for each model, Foxboro Node I/O installation guide excerpt, and customs-compliant commercial invoice with HS code 8537.10.90 clearly stated.

Note: While functionally similar to earlier L0130A variants, newer production batches of L0130AD and L0130AE-0H include improved ESD protection (IEC 61000-4-2 Level 4) and tighter thermal drift specs — confirmed by accelerated life testing at a Midwest calibration lab, which recorded <0.01% full-scale drift over 10,000 hours at 55 °C ambient.

“`

Reviews

There are no reviews yet.