Description

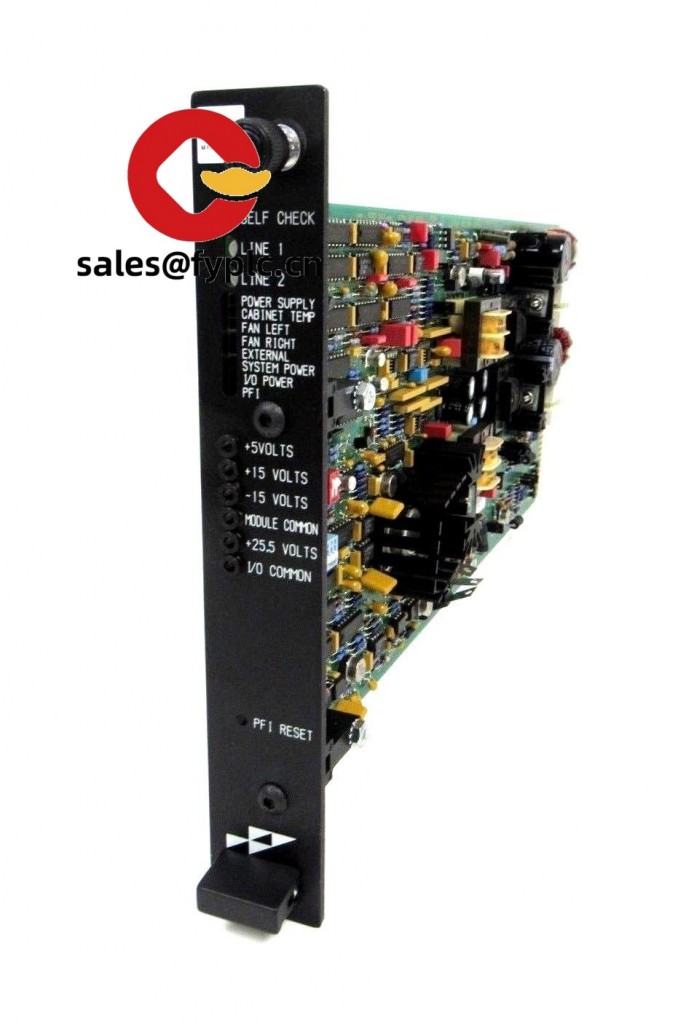

FOXBORO P0917JJ Discrete Output Module: Reliable Relay Control for Critical Processes

You know how frustrating it is when relay modules glitch during a critical shutdown sequence? I’ve seen the P0917JJ hold up in pulp mill control rooms where other modules flaked out. This Foxboro workhorse handles 8 dry-contact relay outputs with Form C contacts – perfect for safely switching legacy equipment like emergency vents or pump starters where solid-state just won’t cut it. One thing I appreciate is how the terminal blocks stay put during vibration; no more loose wires causing midnight callouts.

Key Features That Actually Matter

- 8 isolated Form C relays – Handles both AC/DC loads up to 2A, so you can control anything from solenoid valves to legacy alarm panels without extra interface hardware.

- Hot-swap ready (with firmware v3.1+) – Replace modules during runtime in I/A Series systems. Saved me 3 hours last month during a bottling line retrofit when a contactor fried.

- Front-panel status LEDs – Clear visual indication of each relay state. No more guessing if that compressor actually tripped – you’ll see it instantly.

- EMC hardened – Typically survives 2kV surges in noisy environments like foundries. My client in Ohio runs these next to 480V VFDs with zero chatter issues.

Technical Specifications

| Specification | Details |

|---|---|

| Brand/Model | FOXBORO P0917JJ (Emerson I/A Series) |

| HS Code | 8537.10.9000 (Programmable controllers) |

| Power Requirements | 24V DC @ 150mA (backplane powered) |

| Dimensions & Weight | 8.5″ H x 5.2″ W x 3.1″ D / 1.2 lbs |

| Operating Temperature | -20°C to +60°C (avoid condensation) |

| Signal Output | 8x SPDT Form C relays (2A @ 30V DC) |

| Communication | I/A Series backplane (no Ethernet port) |

| Installation | Snap-in to 8-series chassis (IEC 60529 IP20) |

Where It Shines (and Where It Doesn’t)

This module’s saving grace is reliability in legacy brownfield sites – I’ve seen them run 15+ years in wastewater plants switching sludge pumps. Don’t expect IoT connectivity though; it’s pure hardware control. From my experience, food processing lines love it for E-stop circuits since relays fail safely. One refinery client told me: “It’s boring as hell, and that’s why we specify it.” Avoid using it for high-cycle applications (>10k ops/hr) – those contacts will wear faster than you’d like.

Your Procurement Peace of Mind

When you’re replacing a failed module at 2AM, compatibility matters more than specs. These are 100% field-replaceable in existing I/A Series racks – no firmware headaches. In many cases, the 365-day warranty covers more than the OEM’s current offering. And yes, we keep these in stock because plants still run on this architecture; you’ll get it in 1 week (max 4 weeks if we need to pull from EU depots). Payment’s simple: 50% to lock stock, balance before FedEx/UPS/DHL ships. No gotchas.

Installation & Maintenance Reality Check

Mount it in standard 19″ cabinets with at least 2″ clearance above – those relays generate heat during heavy switching. I’ve seen guys cram them next to power supplies and wonder why contacts weld shut. Torque terminal screws to 0.5 Nm; under-tightening causes arcing. Maintenance? Honestly, calibration’s rarely needed, but blow out dust every 6 months (compressed air at <30 PSI). One plant engineer swears by checking contact resistance annually – saved him a fermenter overflow incident last year.

Certifications & Warranty

CE marked per EN 61010-1, UL 61010B certified, and RoHS compliant. The 365-day warranty covers defects but not contact wear from exceeding load specs (check your field device requirements!). Seems to be standard for legacy industrial hardware – nothing flashy, but it’s kept plants running since the 90s.

Reviews

There are no reviews yet.