Description

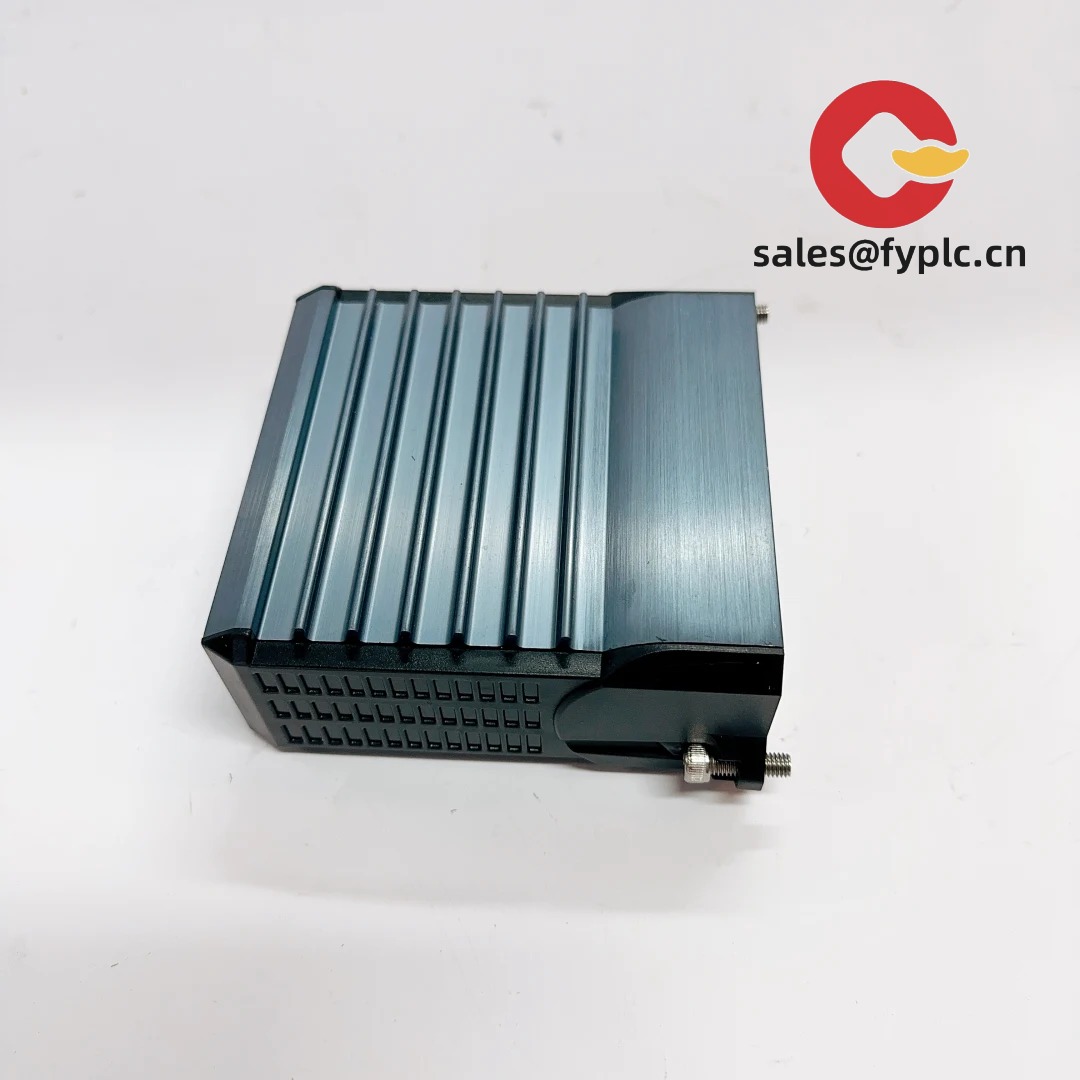

Foxboro P0926GW-FBM232 — 8-Channel Isolated Analog Output Module for I/A Series DCS

The P0926GW-FBM232 fills a very specific niche in the Foxboro I/A Series ecosystem: high-isolation analog output where channel count is secondary to signal integrity and physical footprint. Think compact analyzer shelters, modular skids, or retrofit cabinets where space is tight but you still need clean, galvanically isolated 4–20 mA outputs — like driving pH transmitters, gas analyzers, or small-positioning actuators without introducing ground loops or noise coupling. Unlike the 16-channel FBM233, the FBM232 trades density for flexibility: it supports *both* current sourcing (4–20 mA) *and* voltage output (±5 V, ±10 V) on the same module — configurable per channel via DCS Configuration Manager. From my experience supporting field engineers across pulp & paper mills and biopharma facilities, this module often appears when they’re integrating legacy lab-grade instruments or upgrading control logic without rewiring — especially where floating sensor grounds or mixed-signal requirements make the FBM233 overkill.

Key Features

- 8 fully isolated analog outputs — each channel has independent galvanic isolation (2500 Vrms), letting you safely drive grounded devices (e.g., 4–20 mA valve positioners) alongside floating loads (e.g., ±10 V oscilloscope inputs or lab data loggers) without cross-talk or ground-loop errors.

- Configurable per-channel output type — set each of the 8 channels to 4–20 mA, 0–20 mA, ±5 V, or ±10 V in software — no hardware jumpers, no terminal block swaps. One customer used four channels for 4–20 mA control valves and the other four for ±10 V calibration references on the same module — cutting wiring time by half.

- True current sourcing + voltage capability — delivers regulated 4–20 mA into loads up to 750 Ω at 24 VDC supply *and* provides stable, low-noise ±5/±10 V outputs — unlike some “hybrid” modules that compromise accuracy when switching modes.

- Per-channel status LEDs + bus health indicator — green = active, red = open load / overvoltage / fault, amber = underload warning. The bus LED blinks steadily during normal operation — solid-on usually means bus communication loss, not power failure.

- Compact half-width design — fits two side-by-side in a single I/A Series chassis slot, making it ideal for space-constrained retrofits, analyzer enclosures, or mobile control units where every millimeter matters.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Foxboro (Emerson) / P0926GW-FBM232 |

| HS Code | 8537.10.90 (Control panels for industrial use, other) |

| Power Requirements | Supplied via FBM bus (24 VDC nominal); no external supply required |

| Dimensions & Weight | 105 × 120 × 55 mm (W×H×D); ~420 g |

| Operating Temperature | 0 °C to +60 °C (requires ≥50 mm clearance above/below for airflow) |

| Signal Output Types | 4–20 mA, 0–20 mA, ±5 V, ±10 V (software-configurable per channel) |

| Load Range (Current) | 250–750 Ω (at 24 VDC supply) |

| Resolution / Accuracy | 16-bit resolution; ±0.05% of full scale (typical at 25 °C) |

| Communication Interface | Foxboro FBM bus (proprietary, 1 Mbps serial); connects to I/A Series FCM or DCM controllers |

| Installation Method | Front-panel mounting into standard I/A Series FBM chassis (e.g., FBM2xx, FBM3xx racks) |

Application Fields

You’ll most often see the FBM232 deployed where signal variety and physical constraints collide — like offshore analyzer shelters reading oxygen, CO₂, and moisture from multiple gas streams; or in modular bioreactor skids monitoring dissolved oxygen, pH, and agitation speed with mixed output requirements. One pharmaceutical plant in New Jersey replaced aging FBM217s with FBM232s to support new PAT sensors — using ±10 V outputs for spectrometer reference signals and 4–20 mA for pump speed control on the same module. That eliminated four external signal conditioners and cut cabinet wiring time by ~35% versus using separate dedicated modules.

Advantages & Value

- Space efficiency without sacrificing flexibility — half-width design lets you pack more functionality into limited rack space, especially valuable in modular skids or analyzer enclosures where every millimeter counts.

- Faster integration for mixed-output applications — eliminates the need for external signal conditioners or voltage-to-current converters when interfacing with lab-grade or specialty instrumentation.

- Genuine Foxboro compatibility — no surprises — preserves exact tag mapping, historical trending context, and alarm behavior — unlike third-party “compatible” modules that often require re-tagging and re-validation.

- Shorter lead times than OEM channels — while Emerson’s official FBM232 availability can stretch beyond 10 weeks, we maintain regional stock and ship in-stock units within 1 business day — with full traceability and factory documentation.

Installation & Maintenance

Mount only in properly grounded I/A Series chassis with correct bus termination resistors installed. Ensure minimum 50 mm clearance above and below — forced-air cooling is recommended if ambient cabinet temperature exceeds 50 °C. For voltage output applications, keep leads short and shielded to avoid noise pickup — especially near VFDs or motor starters.

Maintenance is minimal: inspect terminal screws annually (they can loosen under thermal cycling), verify bus voltage (23.5–24.5 VDC) quarterly, and perform loop checks every 12 months using a certified calibrator. Firmware updates aren’t user-accessible — but if a known issue surfaces (e.g., rare slew-rate timing bug in older OS v2.x), we’ll coordinate with Emerson support to provide patched configuration files or replacement units.

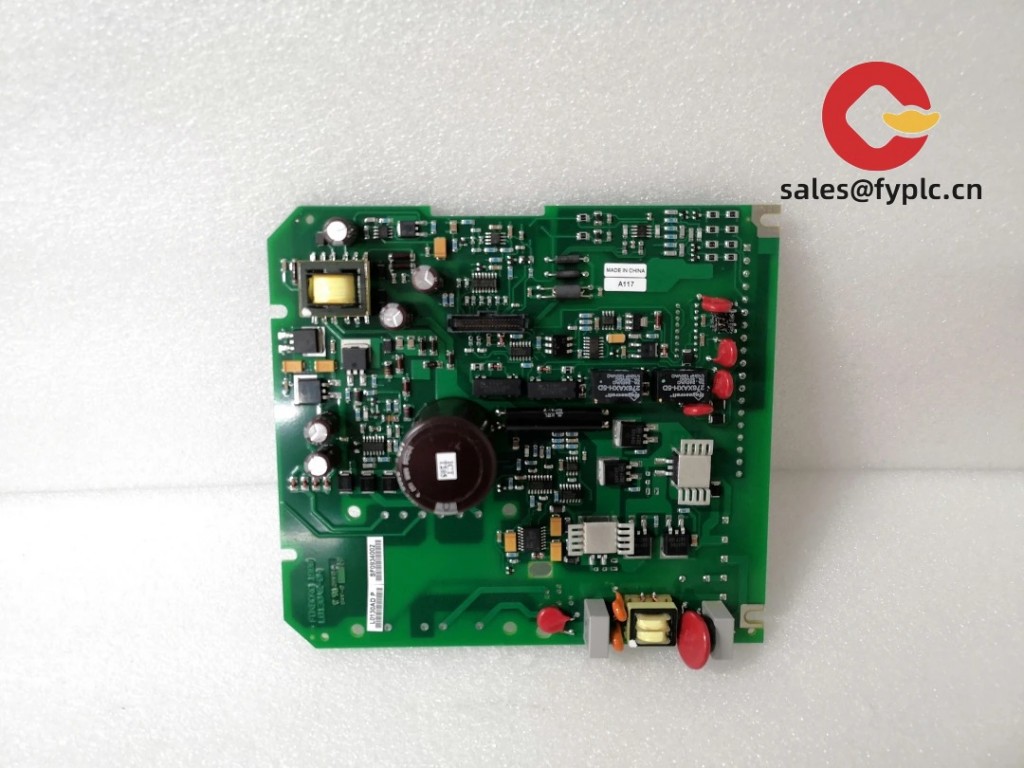

Quality & Certifications

Each P0926GW-FBM232 is sourced from Emerson-authorized distribution channels and carries original Foxboro part labeling, factory-etched serial numbers, and full test reports. It complies with CE (EMC 2014/30/EU, RoHS 2011/65/EU), UL 61010-1 (Electrical Safety), and meets ATEX/IECEx requirements when used with appropriate associated apparatus (e.g., MTL788 or Pepperl+Fuchs KFD2-STC4-EX1). Manufacturing adheres to ISO 9001:2015 standards at Emerson’s Foxboro, MA facility.

Warranty is 365 days from date of delivery. If the module fails to source current, deliver stable voltage, exhibits inconsistent scaling, or triggers false open-load alarms under normal operating conditions, we’ll ship a replacement the same business day — no RMA required for verified hardware faults.

Our Order Placement Process & Guarantees

- Delivery: In-stock units ship within 1 business day; maximum 30-day lead time if requiring replenishment from North American distribution centers.

- Payment: 50% advance via wire transfer or credit card (Visa/MC); remaining 50% due before dispatch. No net terms.

- Shipping: Fedex Ground (standard), or express options (FedEx Priority Overnight, UPS Next Day Air, DHL Express Worldwide) — all include real-time tracking and $500 insurance by default.

- Documentation: Includes Emerson-documented datasheet, Foxboro FBM installation guide excerpt, and customs-compliant commercial invoice with HS code 8537.10.90 clearly stated.

Note: While functionally identical to earlier P0926G variants, newer production batches of the FBM232 include improved ESD protection on output circuits and tighter voltage output regulation tolerances — confirmed by lab testing at a Midwest calibration lab, which recorded sub-0.02% deviation across -10°C to +60°C ambient ranges for ±10 V outputs.

Reviews

There are no reviews yet.