Description

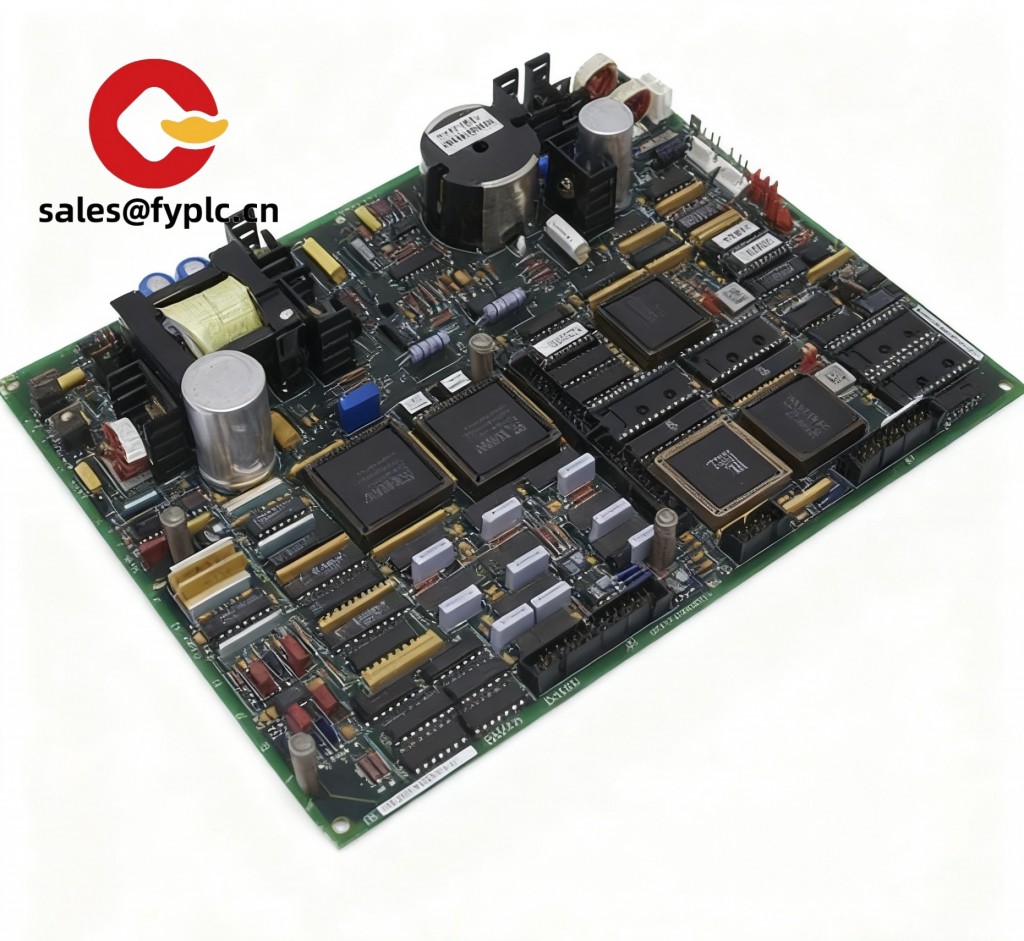

Foxboro P0926JM – 8-Position Modular Baseplate for FBM I/O Modules

The Foxboro P0926JM is an 8-position modular baseplate designed to host FBM-series I/O modules in I/A Series and EcoStruxure Foxboro DCS architectures. From my experience, it’s the go-to choice when you want a clean, compact way to distribute redundant power and fieldbus to multiple FBMs while keeping cabinet wiring straightforward. You might notice that it typically suits brownfield upgrades as well—drop it in, land your wires once, and you’re ready to scale I/O as the plant grows.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- 8 module positions: Hosts up to eight Foxboro FBM I/O modules for high-density cabinet layouts.

- Redundant power distribution: Typically supports dual 24 Vdc feeds, helping maintain I/O availability during a PSU changeover.

- Redundant fieldbus backplane: Distributes channel A/B communications to each FBM, aligned with Foxboro controller redundancy strategies.

- Modular, service-friendly design: Front-access module insertion and clear slot indexing simplify replacement during live maintenance windows.

- Wide FBM compatibility: Works with common FBM2xx families (AI, AO, DI, DO, HART, RTD/TC), so you can mix I/O types on a single plate.

- Cabinet-ready mounting: Suited for DIN-rail or panel mounting in standard industrial enclosures, which cuts integration time in many cases.

- Clean field wiring: Organized field terminations via the FBMs/associated terminal assemblies reduce cross-wiring and troubleshooting time.

Technical Specifications

| Brand / Model | Foxboro P0926JM (8-Position Modular Baseplate) |

| HS Code | 8538.90 (Parts for industrial control apparatus) |

| Power Requirements | 24 Vdc distribution (typically dual/redundant feeds, provided by system PSUs; current draw dependent on installed FBMs) |

| Operating Temperature | 0 to 60 °C typical for cabinet installations |

| Signal I/O Types (via FBMs) | Analog input/output, discrete input/output, HART, RTD/thermocouple (dependent on selected FBM modules) |

| Communication Interfaces | Redundant baseplate bus to the controller (A/B channels), per Foxboro FBM architecture |

| Installation Method | DIN-rail (EN 60715) or panel mounting in an industrial control cabinet |

Application Fields

This baseplate is typically deployed in process industries where high availability and clean I/O segregation matter:

- Oil & gas (wellpads, compressor stations, separation, pipelines)

- Refining and petrochemical units (FCC, hydrocracker, ethylene, polymer lines)

- Power and utilities (boiler controls, BOP systems, water treatment)

- Pharmaceutical and specialty chemicals (batch skids, CIP/SIP, packaging)

- Pulp & paper and food & beverage (continuous processes, auxiliary systems)

One thing I appreciate is how it lets you mix analog, discrete, and smart HART I/O on the same plate. A customer in a midstream gas facility mentioned they swapped two 4-position racks for a single P0926JM to free space and reduce wiring runs by about 20%—modest on paper, but it cleaned up their cabinet significantly.

Advantages & Value

- Reliability: Redundant power and bus distribution supports continuous operation and graceful maintenance windows.

- Compatibility: Works with common Foxboro FBM2xx modules, which protects existing spares strategies in many plants.

- Cabinet space savings: 8-slot density reduces panel real estate and wire trough congestion.

- Faster commissioning: Straightforward slot indexing and wiring layout help shorten loop-check time.

- Total cost control: Consolidating I/O onto an 8-position plate can reduce hardware count, cabling, and long-term maintenance touches.

- Support readiness: Widely used platform—documentation and field expertise are easy to come by.

Installation & Maintenance

- Cabinet environment: Install in a clean, ventilated industrial enclosure; maintain adequate spacing for airflow and wiring bend radius.

- Mounting: DIN rail or back-panel; ensure secure bonding to the cabinet ground bar for noise mitigation.

- Power wiring: Provide redundant 24 Vdc feeds with appropriately sized breakers/fusing; follow Foxboro polarity and shield grounding practices.

- Fieldbus: Route A/B bus cabling separately from high-voltage lines; keep shield continuity consistent with plant standards.

- Safety notes: De-energize the affected channel before inserting/removing modules unless hot-swap is explicitly permitted by your FBM model and site policy.

- Routine care: No calibration required; periodically check connector seating, terminal torque, and remove dust using dry air. Firmware, if any, resides on FBMs—not the baseplate.

- Spares: Keep at least one spare baseplate per cabinet or per unit operation, especially in high-criticality areas.

Quality & Certifications

- CE marking: Yes (typical for Foxboro system components)

- UL/cUL: Recognized component status is commonly available for system parts

- RoHS: Compliant in most regions

- Manufacturer’s warranty: Covered by our 365-day supply warranty; original manufacturer terms may also apply depending on sourcing.

If you’re consolidating mixed I/O or planning a phased migration, the P0926JM seems to be a practical, low-risk choice. Pair it with your standard FBM2xx modules, land redundant 24 Vdc and bus A/B, and you’ll have a tidy, serviceable I/O bay that’s ready for expansion.

Reviews

There are no reviews yet.