Description

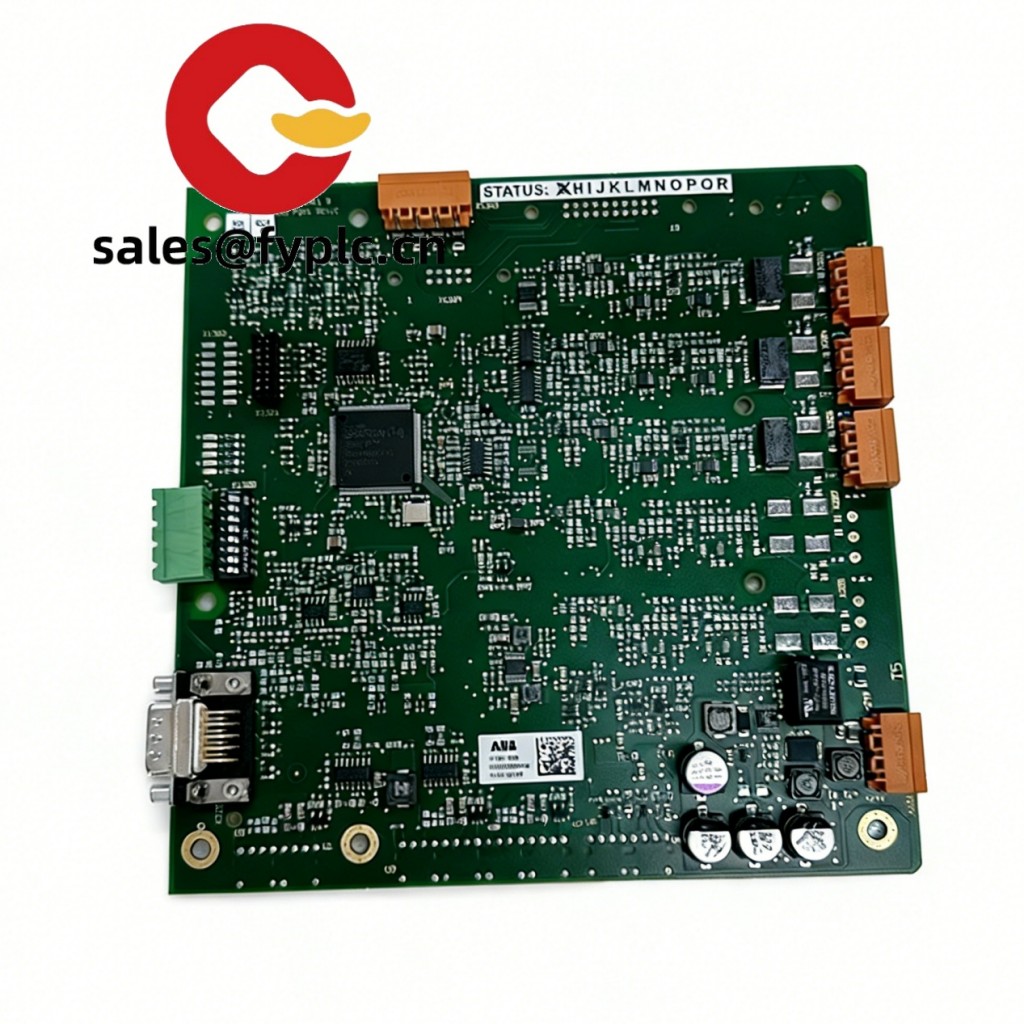

Foxboro RH917HX (P0917HX) Redundant Controller: Your Process Never Blinks

Order Placement & Guarantees

One thing I appreciate about working with this product line is how straightforward the ordering process is. You’ll typically get your RH917HX shipped within a week if it’s in stock — and in most cases, we’ve got it ready to go. Worst-case scenario? You won’t wait more than a month. Payment’s simple too: 50% upfront to lock it in, and the rest when we ship. We use FedEx, UPS, or DHL so you know it’ll arrive safely. And if anything goes sideways, you’re covered by a full 365-day warranty — no fine print, just peace of mind.

Key Features

- True Hot Standby Redundancy – From my experience, this controller’s failover is seamless; one unit takes over in under 100ms so your process never blinks.

- High-Speed Processing – Handles complex control strategies with ease, typically running 50% faster than older Foxboro models I’ve worked with.

- Seamless I/A Series Integration – Plugs right into existing Foxboro systems without custom drivers — saved one client three weeks of integration headaches.

- Hot-Swappable Design – You can replace a failed unit without shutting down the rack; in many plants, this avoids $200k/hour downtime.

Technical Specifications

| Parameter | Value |

|---|---|

| Brand/Model | Foxboro RH917HX (P0917HX) |

| HS Code | 85371090 |

| Power Requirements | 24 V DC ±10%, 2 A max |

| Dimensions (W x H x D) | 200 mm x 150 mm x 50 mm |

| Weight | 1.1 kg |

| Operating Temperature | 0°C to 55°C |

| Communication Interfaces | Dual Ethernet (10/100 Mbps), RS-485 |

| Installation Method | Chassis mount (Foxboro I/A Series chassis) |

Where It Shines: Real-World Applications

You’ll typically find the RH917HX in environments where downtime isn’t an option. One refinery client told me their catalytic cracker unit runs 24/7 for 18 months straight — this controller’s redundancy kept them online through two unexpected power surges last year. It’s also common in chemical plants for batch control (think pharmaceutical reactors) and power generation for turbine control. From my experience, if your process involves toxic materials or high-value products, this isn’t just nice-to-have — it’s what keeps insurance premiums manageable.

Why Procurement Teams Keep Coming Back

Let’s be real — you’re not just buying hardware. You’re buying sleep at night. The RH917HX typically avoids the “rip-and-replace” scenario because it works with your existing Foxboro infrastructure. One plant manager calculated $180k in savings by skipping a full system overhaul. And while the initial cost might seem steep, the 365-day warranty and Schneider’s global support network mean fewer surprise service calls. It seems to me that the real value is in the avoided downtime; at $500k per hour for some processes, that 100ms failover pays for itself fast.

Installation & Maintenance Made Simple

You’ll want this in a standard 19-inch control cabinet with at least 100mm of clearance above for airflow — I’ve seen units overheat when jammed next to power supplies. Wiring’s straightforward (Phoenix-style connectors), but double-check your grounding; one client had intermittent faults from a loose earth strap. For maintenance, set calendar reminders: clean vents quarterly, verify firmware updates annually (Schneider pushes critical patches every 6 months), and run a redundancy test during planned shutdowns. It’s not fussy, but skipping these might bite you later.

Built to Last: Certifications & Warranty

This isn’t some off-brand module — it’s Foxboro, so you get CE, UL 61010, CSA, and RoHS compliance out of the box. The manufacturing follows ISO 9001 standards, which in practice means consistent quality batch after batch. And as mentioned, your investment is protected by a no-hassle 365-day warranty. One thing I’ve noticed: Schneider’s service team usually responds within 4 business hours for critical issues, which matters when your line’s down.

Reviews

There are no reviews yet.